O-shaped rotary engine

A rotary engine and engine technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as low energy conversion efficiency, loss of mechanical energy, and high noise, and achieve high energy conversion efficiency, easy processing and production, The effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

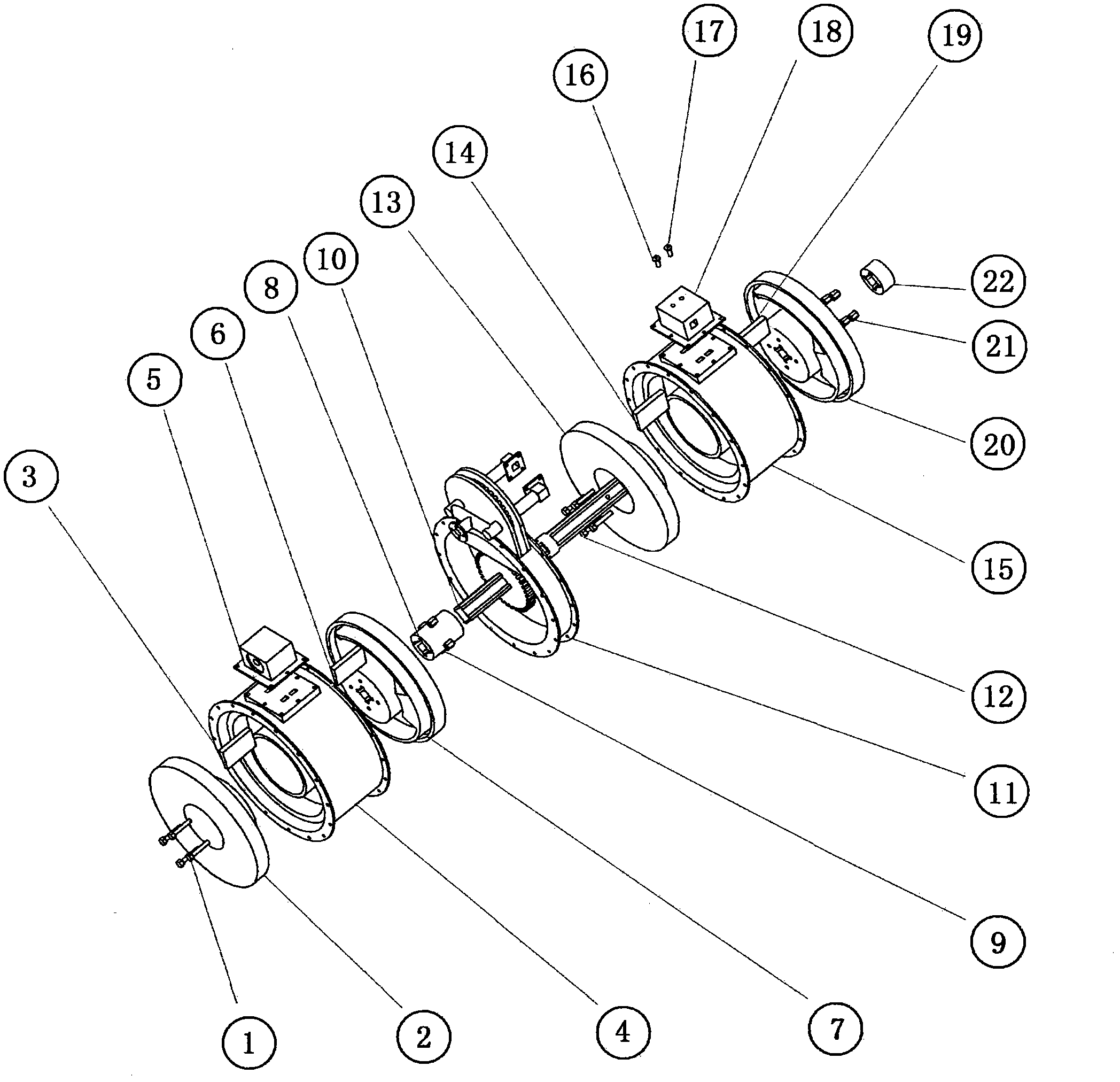

[0037] Structural features of O-type rotary engine:

[0038] like figure 1 shown. Compressor rotor fastening screw (1), compressor inner rail rotor (2), compressor inner diaphragm (3), compressor stator (4), compressor outer diaphragm (6), compressor outer rail rotor ( 7), the compressor rotor fastening nut (9) is respectively connected with the power machine rotor fastening screw (12), the power machine rotor (13), the power machine inner partition (14), the power machine stator (15), and the power machine outer partition (19) 1. The power machine outer guide rail rotor (20) and the power machine rotor fastening nut (21) have the same structure. In specific implementation, the volume of the compressor should be greater than or equal to the volume of the power machine, and the volume of the compressor is larger than the volume of the power machine. , the higher the compression ratio of the fuel-air mixture at the ignition moment. Both the compressor and the power machine ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com