Low emission gas combustion furnace and its combustion air configuration method

A gas combustion, combustion-supporting air technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of increasing blower power and power consumption, easily causing surge, etc., to avoid the generation of carbon monoxide and local High temperature, stable and reliable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings, but this embodiment is not used to limit the present invention. Any similar structure and similar changes of the present invention should be included in the protection scope of the present invention. The dots in both indicate the relationship of and.

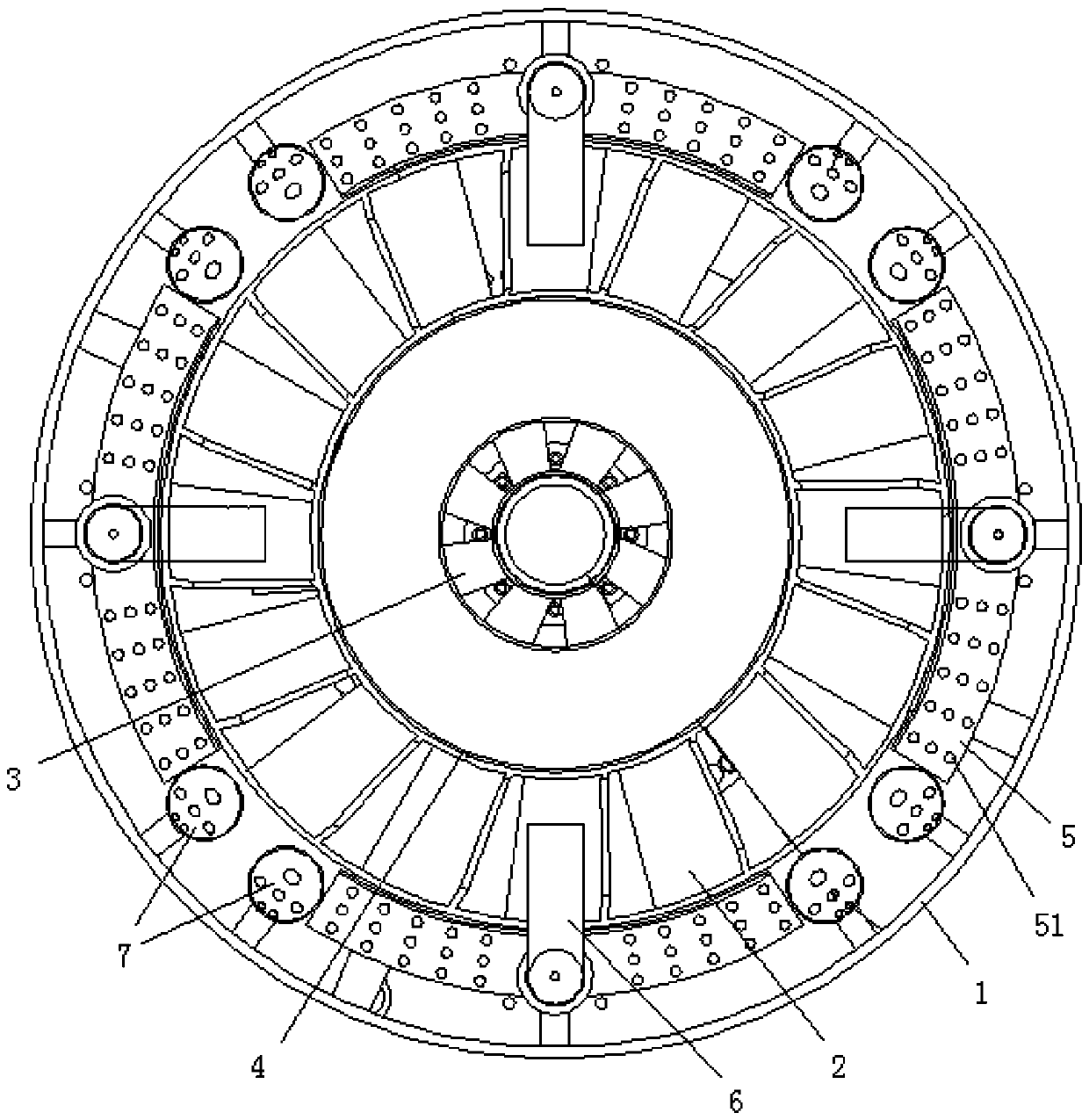

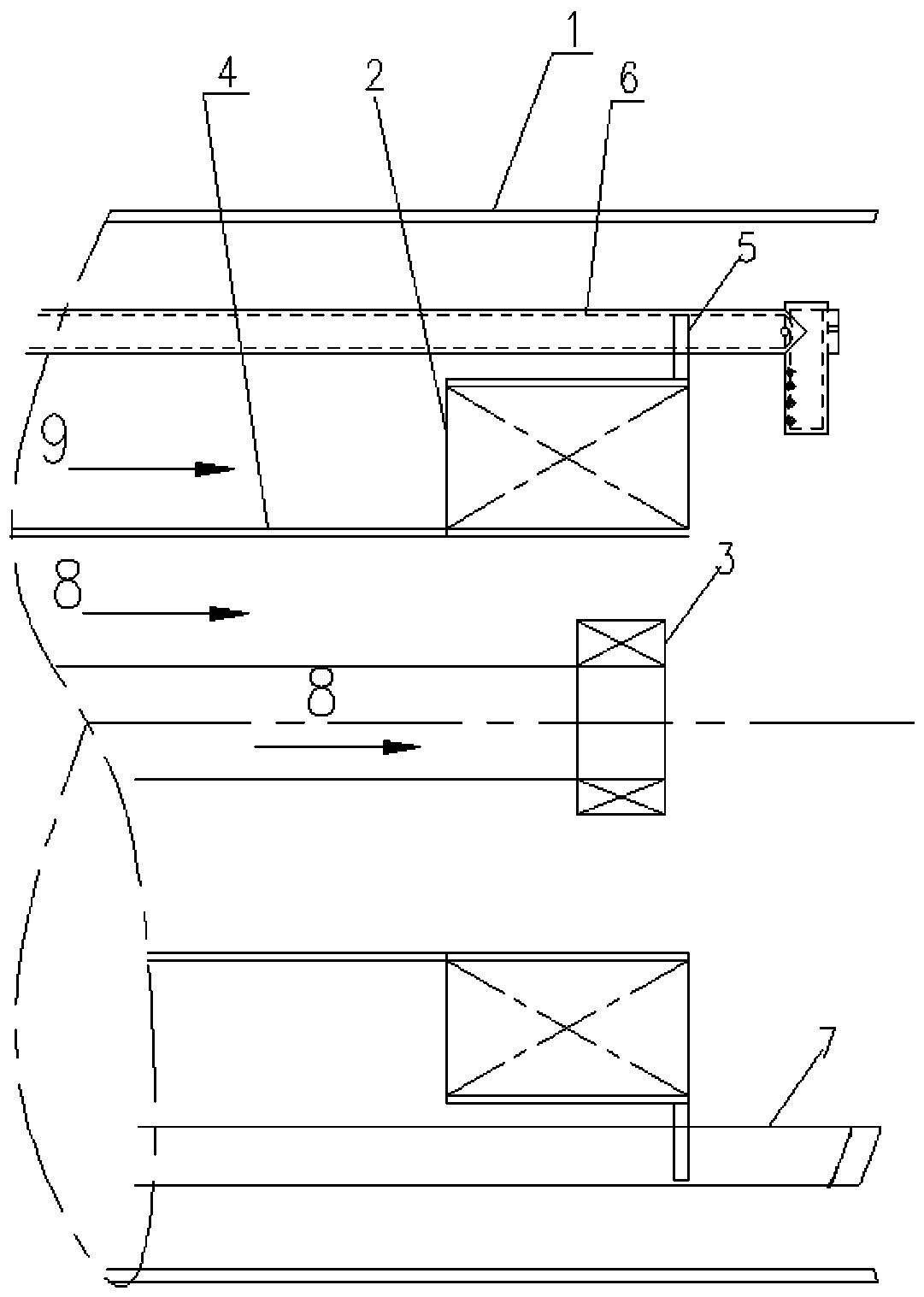

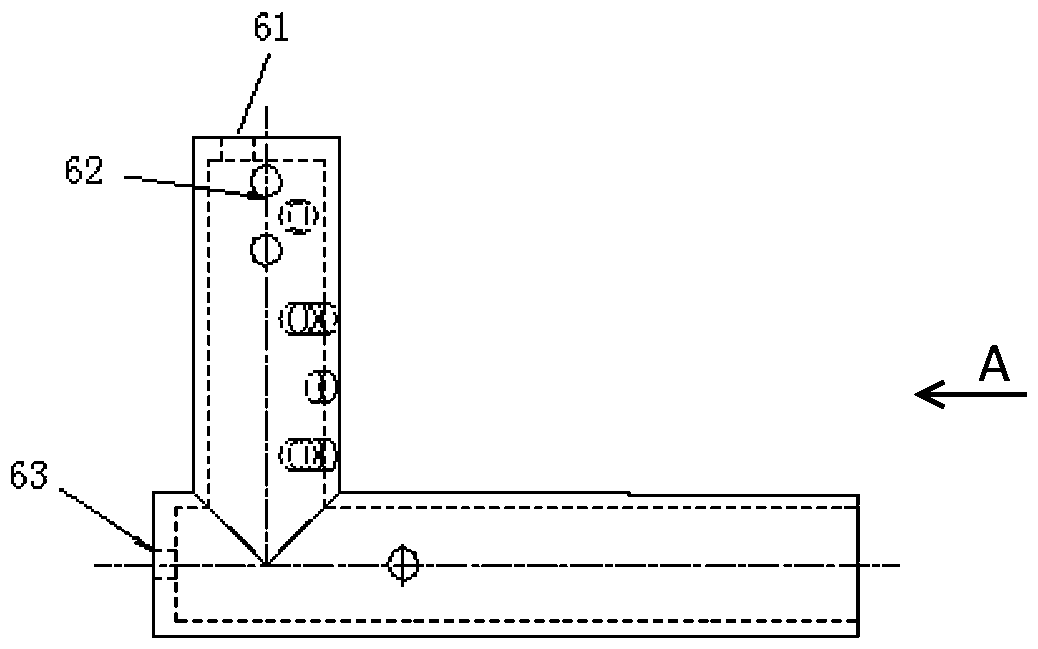

[0024] Such as Figure 1-Figure 5 As shown, the low-emission gas combustion furnace provided by the embodiment of the present invention includes a throat 1, and a first cyclone 2, an intermediate tube 4, and a second cyclone 3 respectively installed in the throat 1. Its characteristics are:

[0025] The throat 1, the first cyclone 2, the intermediate tube 4, and the second cyclone 3 are sleeved coaxially in sequence from the outside to the inside. The inner wall of the first cyclone 2 and the intermediate tube 4 The outer walls are connected and the ends are flush;

[0026] The outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com