Component mounting device

A technology for installing devices and components, applied in the direction of electrical components, electrical components, etc., can solve the problems of large weight and cost increase of component installation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

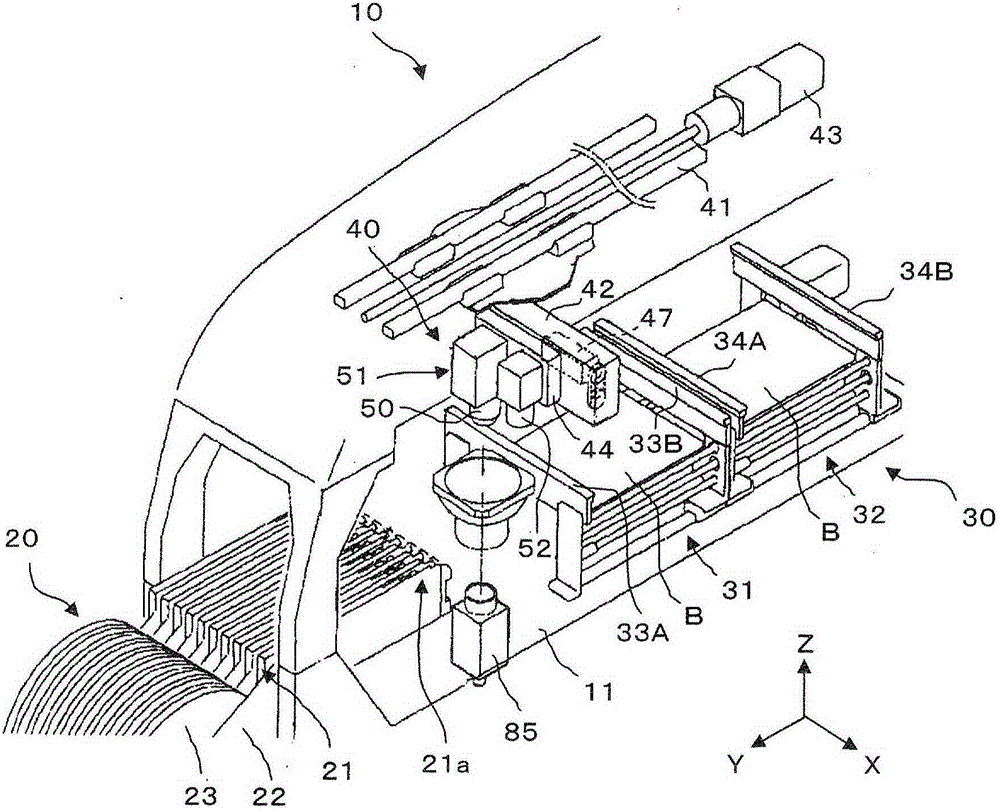

[0029] Embodiments of the present invention will be described below based on the drawings. like figure 1 As shown, the component mounting device 10 includes a component supply device 20 , a board transfer device 30 , and a component transfer device 40 .

[0030] As an example, the components supply apparatus 20 is configured so that a plurality of tape feeders 21 are arranged side by side in the X-axis direction on the base 11 . The tape feeder 21 is detachably attached to the main body frame 22 detachably attached to the base 11, and has a structure in which a plurality of electronic components (hereinafter referred to as components) are wound and accommodated at intervals. The tape formed in one row is supplied to the tape reel 23 . Inside the tape feeder 21, although not shown in the figure, there is built-in a motor which becomes the driving source of the pitch conveyor belt, and the motor is used to send the tape one pitch at a time, and the components accommodated in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com