Method for judging life of air purifier filter screen

An air purifier and purifier technology, applied in the field of air purification, can solve problems such as different air volume, inability to distinguish machine gears, and different filter sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

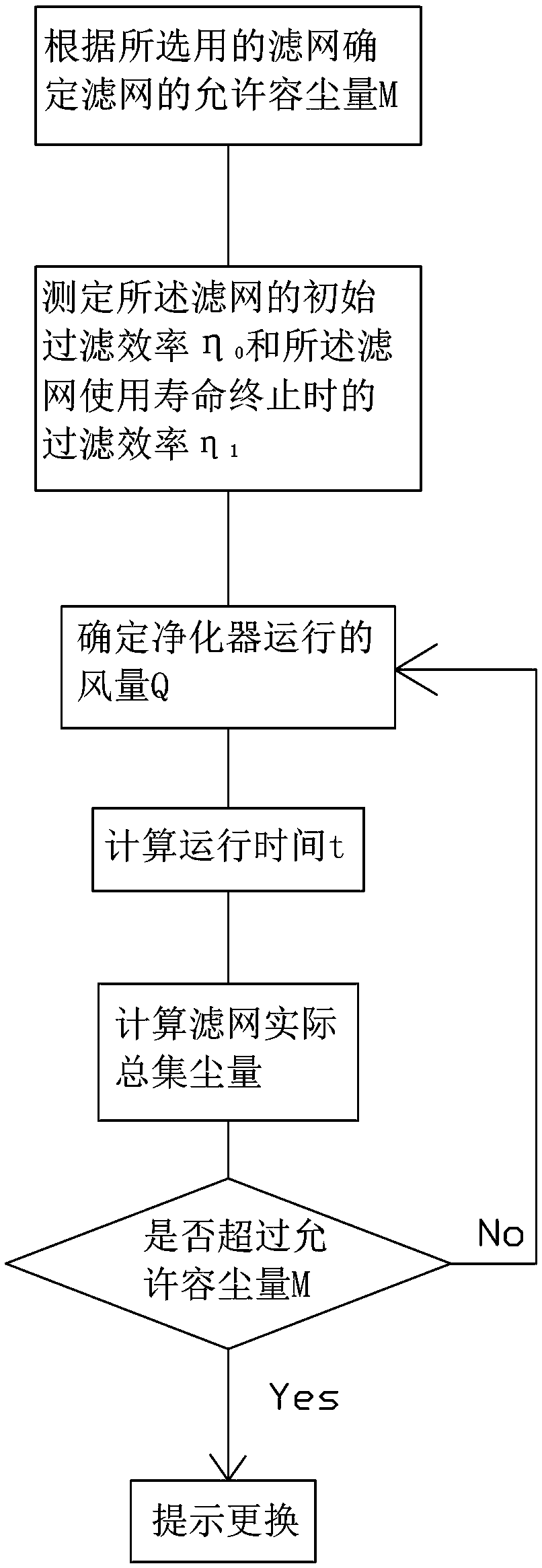

Method used

Image

Examples

Embodiment 1

[0046] 1) The allowable dust holding capacity M of the selected filter is 20g;

[0047] 2) measure the filtering efficiency η of described strainer to be 99% 0 ;

[0048] 3) The air volume Q of the purifier is low-grade 1.5m 3 / min);

[0049] 4) t read by the timer 0 , t 1 , t 2 ...t k point in time;

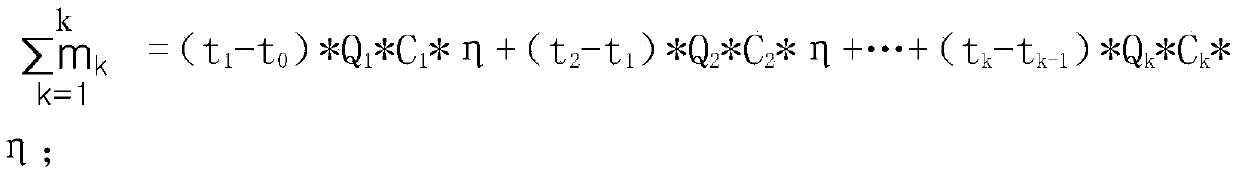

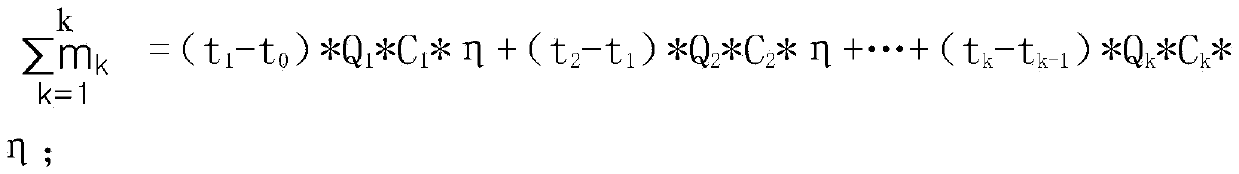

[0050] 5) Dust concentration C is 10μg / m 3 , then the dust collection capacity of the filter during the working hours is m=△t*C*Q*η*10 -6 =1.5*10*99%*1=14.85 μg, through the timer t installed in the air duct of the air purifier 0 , t 1 , t 2 ...t k Read the data of the machine's operating gear at the time point, and obtain the air volume at the time point as Q 0 , Q 1 , Q 2 …Q k . Read the data of the dust sensor, and obtain the dust concentration at each time point as C 0 、C 1 、C 2 …C k , the actual total dust collection capacity of the filter is

[0051] 6) Σ ...

Embodiment 2

[0054] 1) The allowable dust holding capacity M of the selected filter is 20g;

[0055] 2) measure the filtering efficiency η of described strainer to be 99% 0 ;

[0056] 3) The air volume Q of the purifier is a high-grade 5m 3 / min;

[0057] 4) t read by the timer 0 , t 1 , t 2 ...t k point in time;

[0058] 5) Dust concentration C is 100μg / m 3 , then the dust collection capacity of the filter during the working hours is m=△t*C*Q*η*10 -6 =5*100*99%*1=495 μg, through the timer t installed in the air duct of the air purifier 0 , t 1 , t 2 ...t k Read the data of the machine's operating gear at the time point, and obtain the air volume at the time point as Q 0 , Q 1 , Q 2 …Q k . Read the data of the dust sensor, and obtain the dust concentration at each time point as C 0 、C 1 、C 2 …C k , the actual total dust collection capacity of the filter is

[0059] 6) Σ ...

Embodiment 3

[0062] 1) The allowable dust holding capacity M of the selected filter is 20g;

[0063] 2) measure the filtering efficiency η of described strainer to be 99% 0 ;

[0064] 3) The air volume Q of the purifier is 3m in the middle range 3 / min;

[0065] 4) t read by the timer 0 , t 1 , t 2 ...t k point in time;

[0066] 5) Dust concentration C is 100μg / m 3 , then the dust collection capacity of the filter during the working hours is m=△t*C*Q*η*10 -6 =297μg, through the timer t installed in the air duct of the air cleaner 0 , t 1 , t 2 ...t k Read the data of the machine's operating gear at the time point, and obtain the air volume at the time point as Q 0 , Q 1 , Q 2 …Q k . Read the data of the dust sensor, and obtain the dust concentration at each time point as C 0 、C 1 、C 2 …C k , the actual total dust collection capacity of the filter is

[0067] 6) Σ m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com