Aluminum Alloy Extrusion Sheet Die with Adjustable Surface Angle

An aluminum alloy and panel technology, applied in the field of aluminum alloy profiles, can solve the problems of easy occurrence of wrinkles or cracks, inability to meet, etc., and achieve the effects of improving the rendering of environmental atmosphere, improving decoration and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

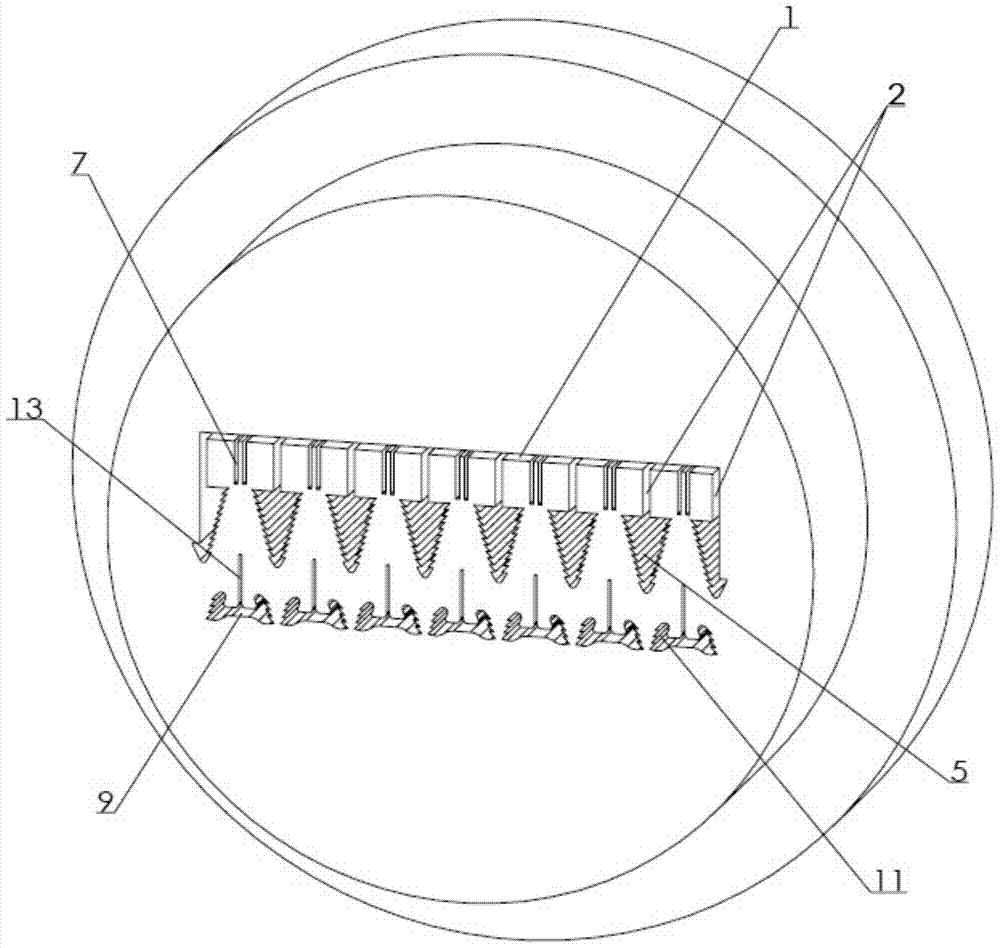

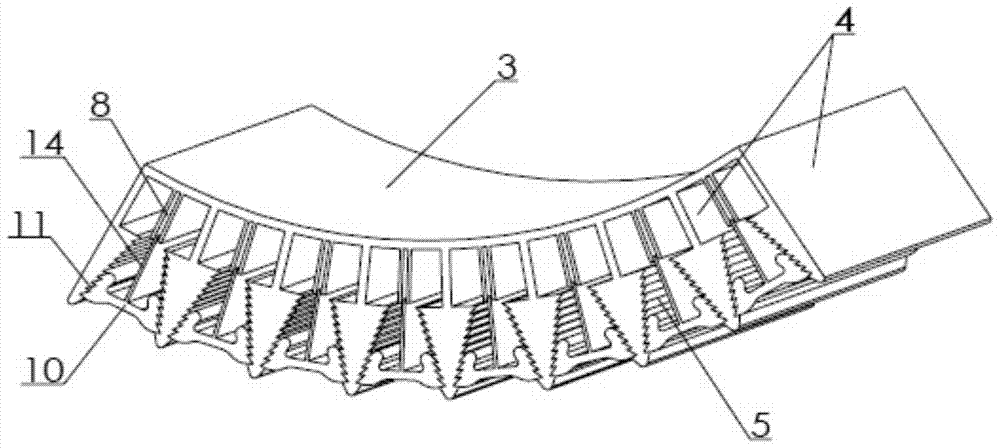

[0012] Examples of the present invention figure 1 , 2 As shown, the aluminum alloy extruded plate mold with adjustable internal angle has a panel flow channel 1 and a wing plate flow channel 2, which is used to extrude an aluminum alloy panel 3 and a wing plate 4, and the cross section of the panel flow channel is straight , the extruded panel is used as a decorative surface. It is a flat plate before it is used. There are at least three wing flow channels. This embodiment is nine pieces. The specific number can be set according to needs. The wing plate flow channel and the panel flow channel Vertically, the wing plate flow channel is equidistantly distributed from one side edge to the other side edge in the width direction of the panel flow channel and connected to the panel flow channel, and the adjacent wing plate flow channel is away from the outer half of the panel. The opposite sides are symmetrically distributed The inverted tooth runner 5 is used for extrusion to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com