Aluminum alloy extruded plate with adjustable internal angle of curved surface

An aluminum alloy and panel technology, applied in the field of aluminum alloy profiles, can solve the problems of easy occurrence of wrinkles or cracks, inability to meet, etc., and achieve the effects of improving the rendering of environmental atmosphere, improving decoration and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

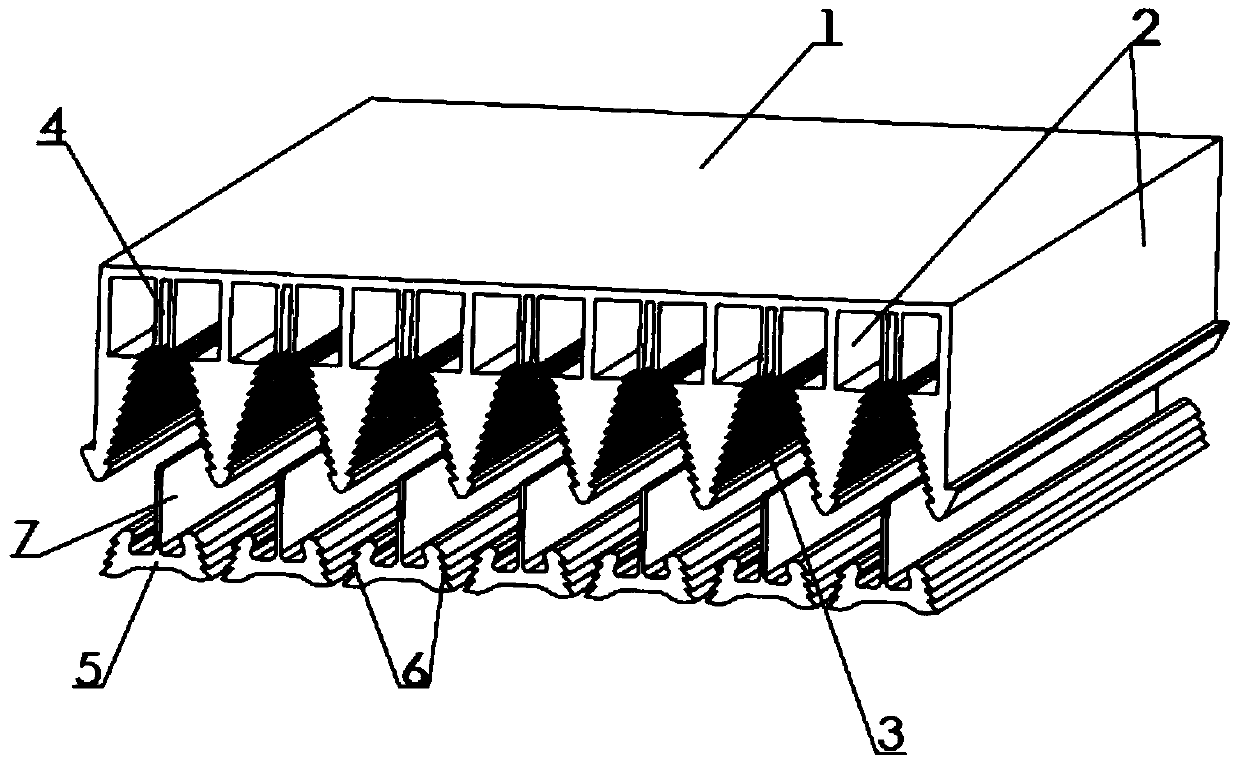

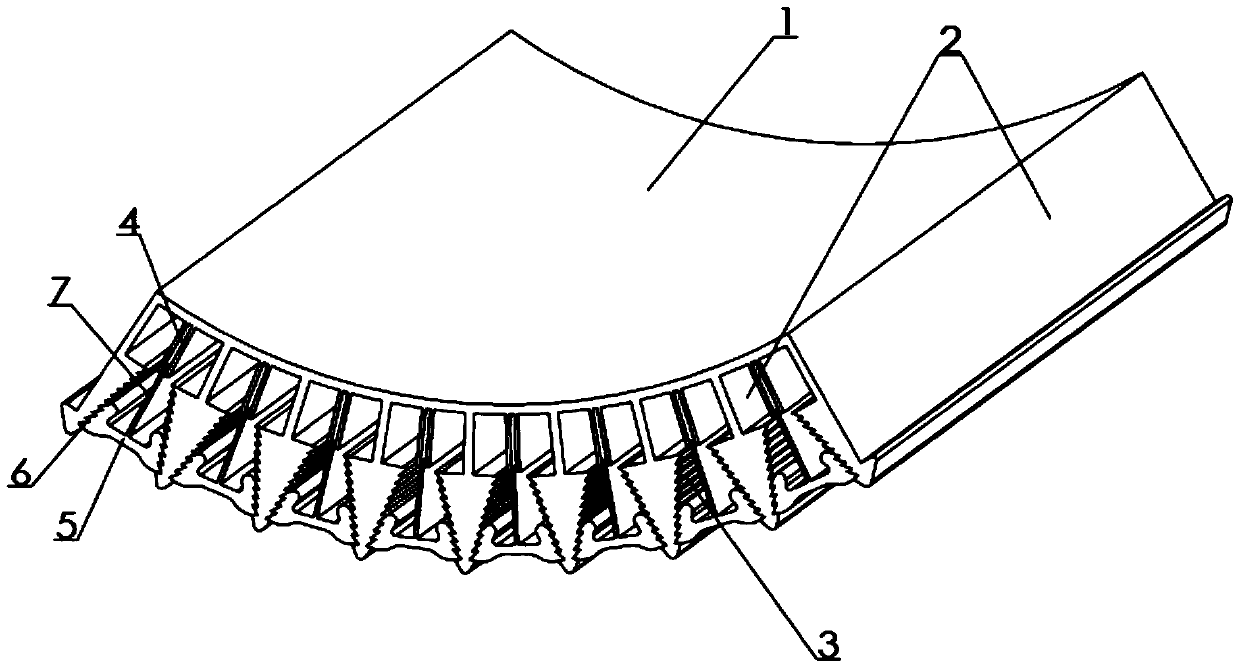

[0012] Examples of the present invention figure 1 , 2 As shown, the aluminum alloy extruded plate with adjustable internal corners is provided with a panel 1 and a wing 2, the panel is used as a decorative surface, and is a flat plate before use, and the wing is at least three pieces, nine pieces in this embodiment, The specific quantity can be set as needed. Both the panel and the wing plate are long strip plates. The longitudinal direction of the wing plate is the same as the longitudinal direction of the panel and the width direction of the wing plate is perpendicular to the back of the panel. The edge of the other side is equidistantly distributed and connected to the back of the panel, and the opposite sides of the adjacent wing plate away from the outer half of the panel are provided with symmetrically distributed inverting teeth 3, and the inverting teeth on each side are more than five levels. This embodiment There are ten levels of barb teeth on each side, and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com