Fusion welding method for copper plates and alloys thereof

A technology of fusion welding, alloy, applied in the field of arc welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The present invention comprises the steps:

[0039] 1. Preparation before welding:

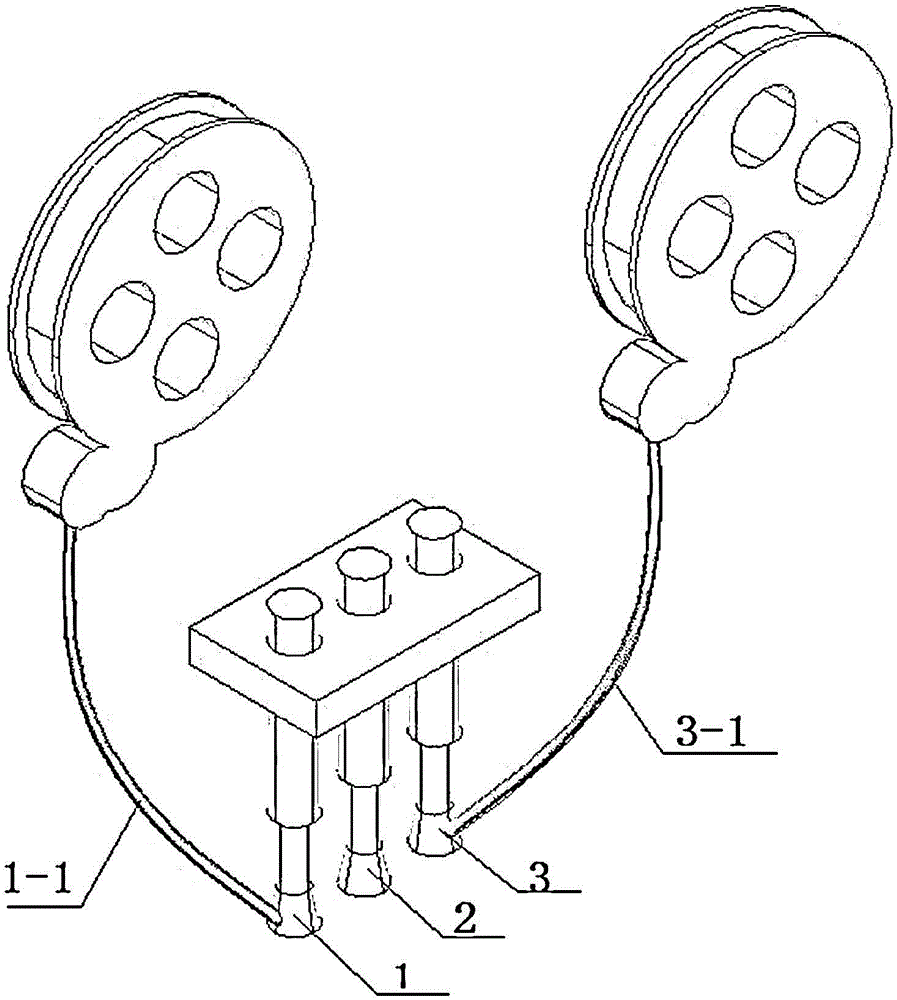

[0040] (1) According to the size of the weldment, place the support legs of the weldment on the welding site, set at least 6 under each base metal, and weld the bottom line terminal on a certain support leg.

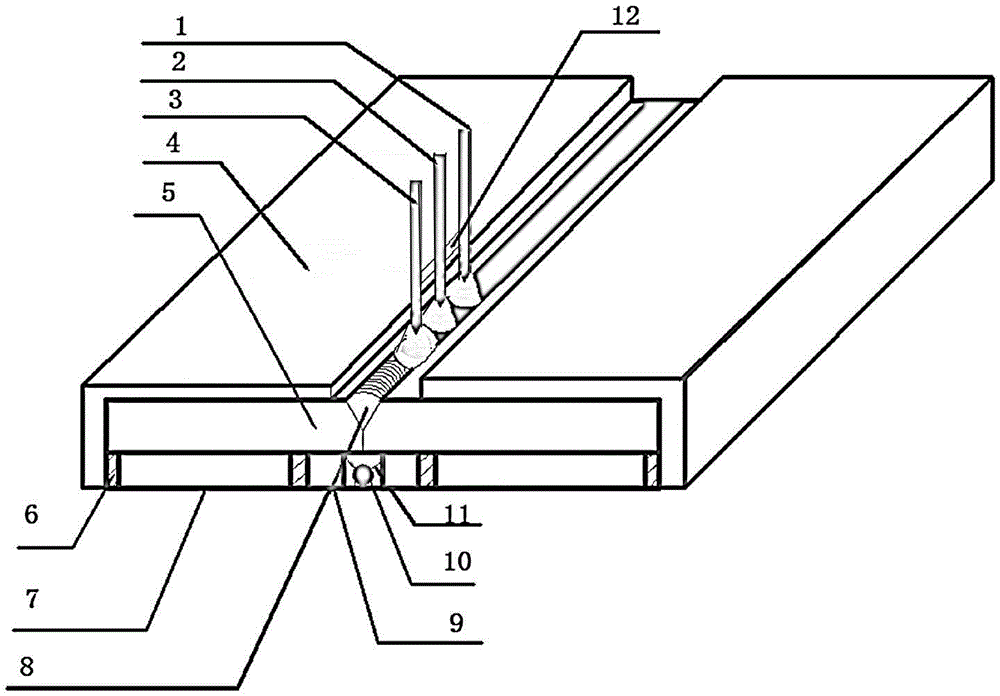

[0041] (2) Install a preheating temperature control system on the working table where the weld is located, and evenly distribute the flame generated by the heater on both sides of the base metal weldment.

[0042] (3) Lay insulation materials, such as refractory bricks or asbestos felt, on all areas of the working platform under the bottom of the weldment except the preheating temperature control system.

[0043] (4) Assembling welded parts: Place the prepared copper parts to be welded on the supporting legs by lifting equipment, and reserve a gap between the joints according to the process requirements.

[0044] (5) According to the operating range of the welding manipulator, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com