Extrusion device for processing rubber

An extrusion device and rubber technology, used in the field of plastic molding or connection, can solve the problems of low extrusion pressure and rubber that does not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

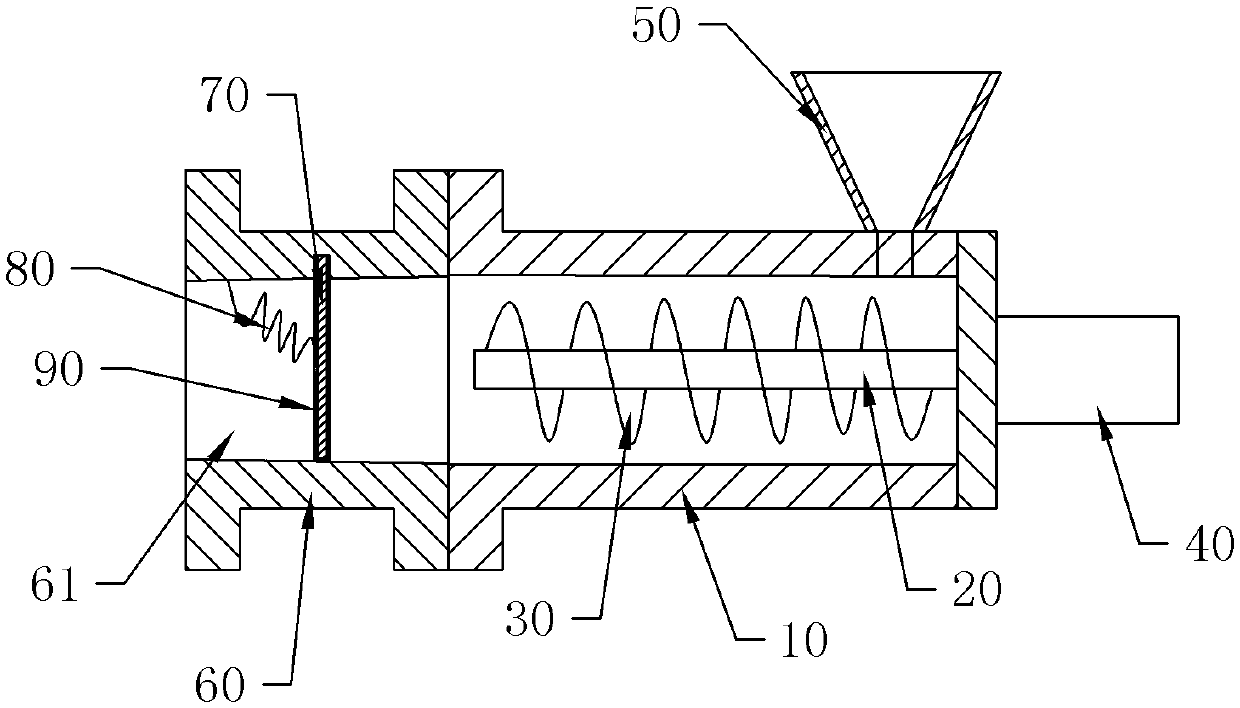

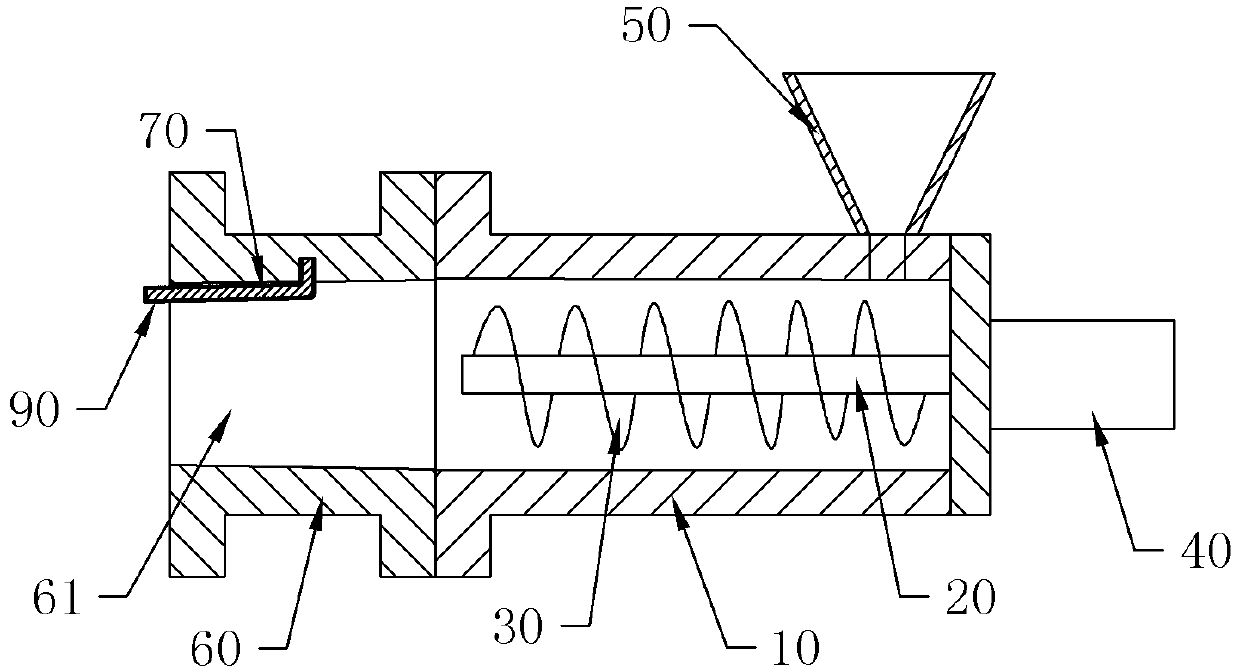

[0018] The reference signs in the drawings of the description include: extrusion cylinder 10, rotating shaft 20, extrusion screw 30, servo motor 40, feed hopper 50, transition section 60, transition chamber 61, spring steel sheet 70, compression spring 80, plastic Layer 90.

[0019] The embodiment is basically as attached figure 1 Shown: an extrusion device for rubber processing, including an extrusion cylinder 10, a rotating shaft 20, an extrusion screw 30 and a power source for driving the rotation of the rotating shaft 20. The power source of this embodiment is a servo motor 40, and the extrusion screw 30 is connected to On the rotating shaft 20, an extrusion chamber is arranged in the extrusion cylinder 10, the rotating shaft 20 is located in the extrusion chamber, and the extrusion cylinder 10 is provided with a feed hopper 50 communicating with the extrusion chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com