Hand held machine tool with dust extraction

A technology of hand tools and dust collection devices, which is applied in the direction of manufacturing tools, portable motorized devices, metal processing machinery parts, etc. It can solve the problems of fine dust passing, clogging, emptying and cleaning troubles, etc., and achieve improved filtration and air penetration The effect of high performance and large filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

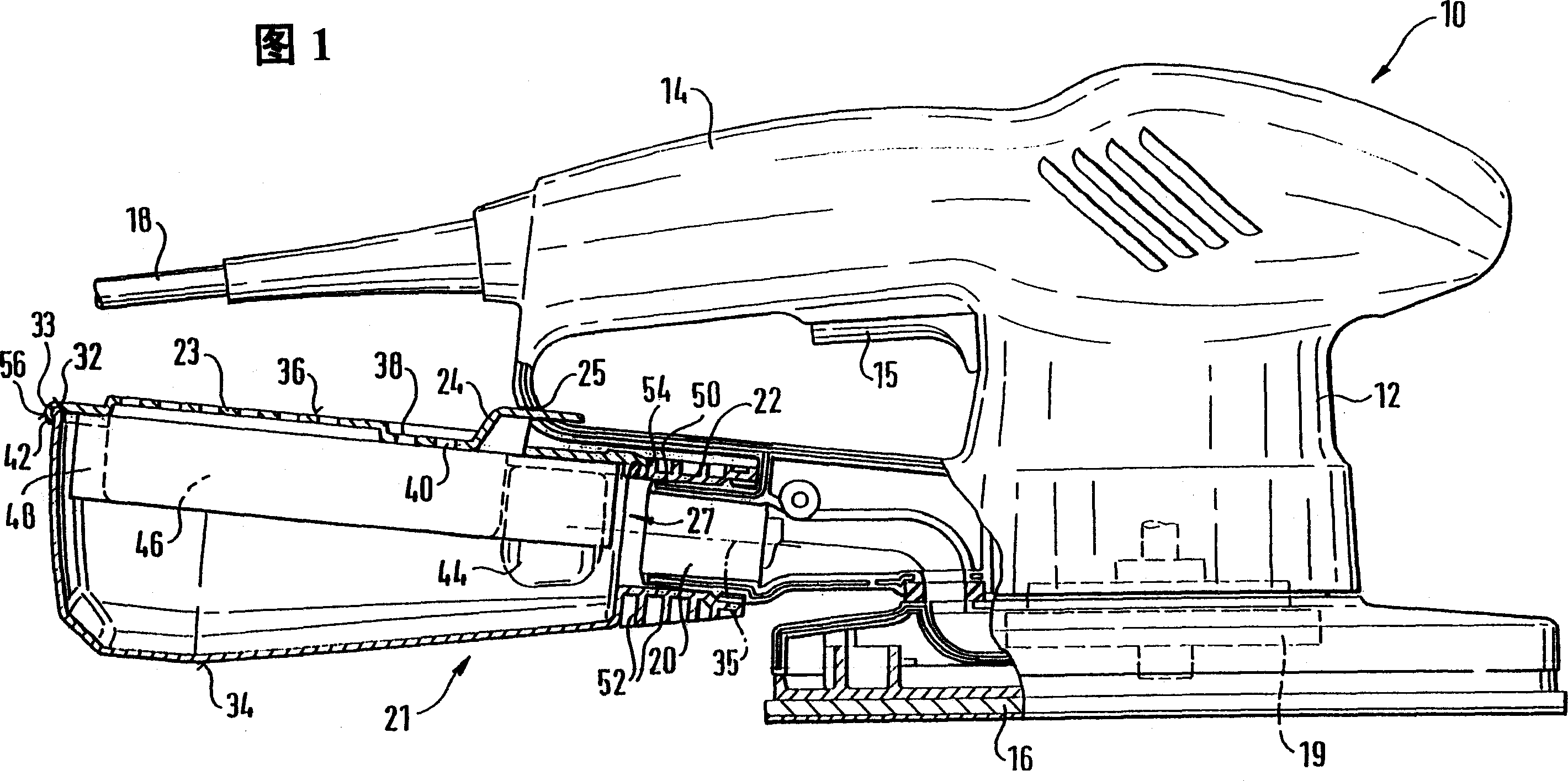

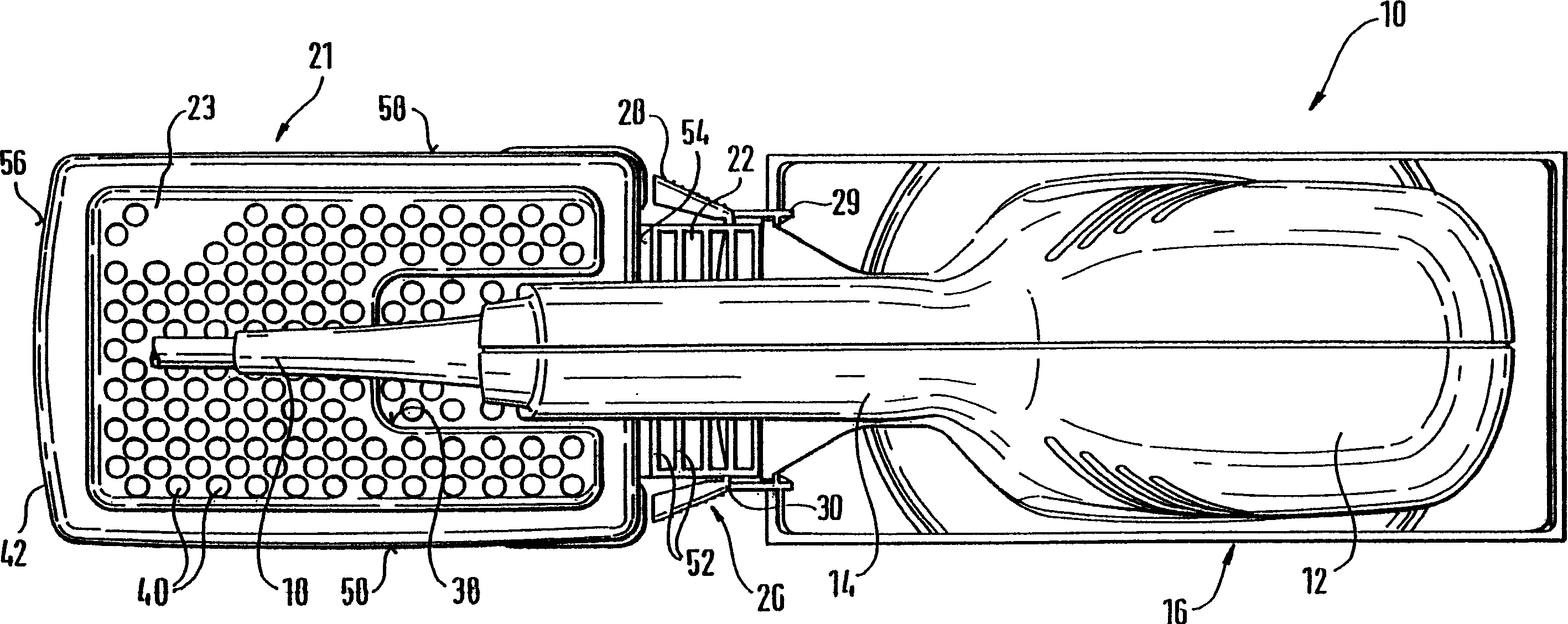

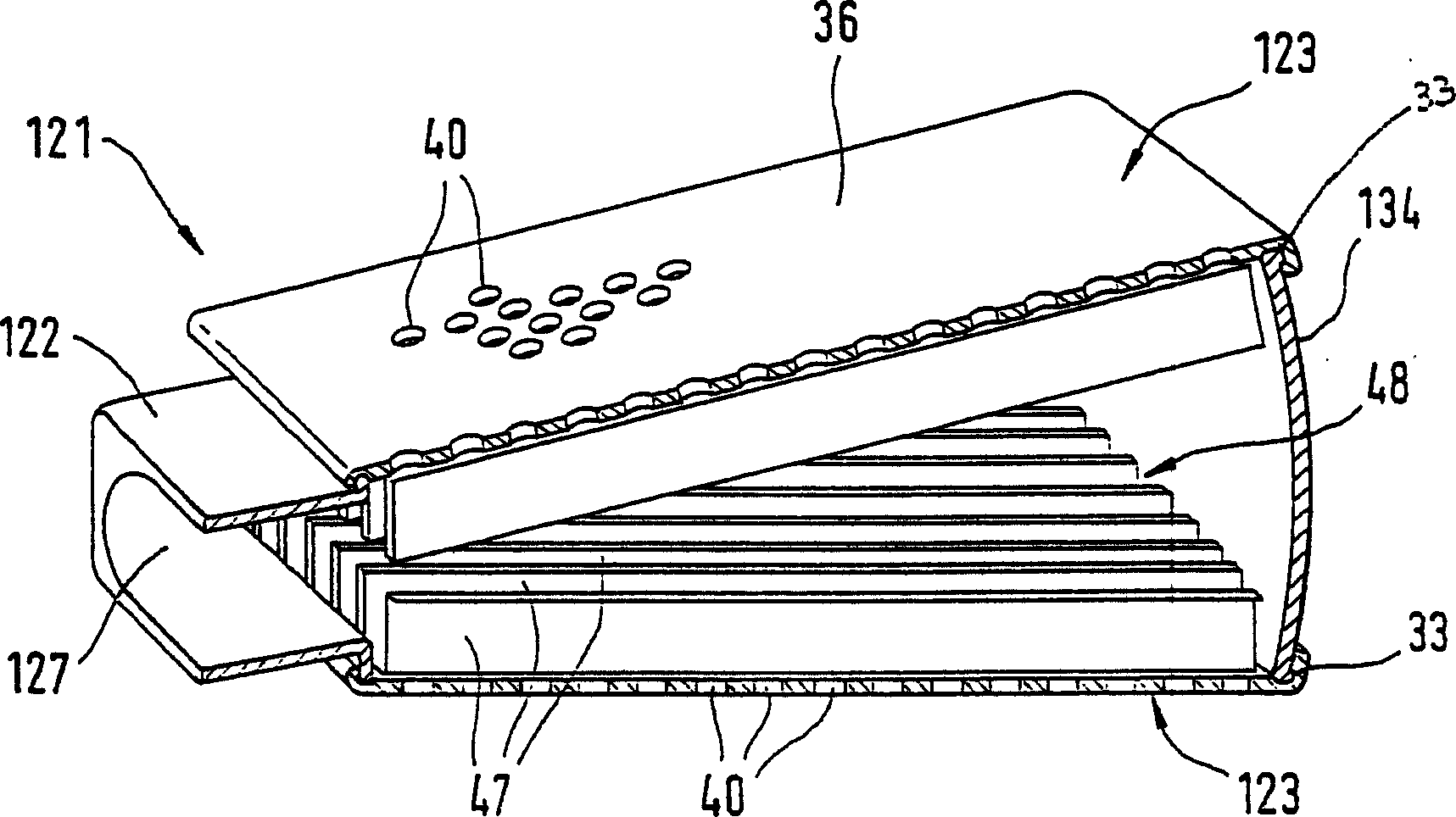

[0035] 1 shows a longitudinal sectional view of a hand power tool 10 designed as a superfinishing grinder, with a housing 12 having a handle 14 with a switch 15 and a tool 16 configured as a grinding plate with a through hole. It is movably fixed on the bottom surface of the machine tool. The hand power tool 10 has a connection cable 18 on the rear end of the handle 14 and a fan wheel 19 inside the housing 12 . When the hand tool machine is in operation, the fan impeller creates a negative pressure above the grinding plate 16 or between the grinding plate 16 and a workpiece, through which, when the hand tool machine 10 is running, the grinding dust passes through the through holes of the grinding plate 16 to be absorbed Suction is fed via a discharge connection 20 of the housing 12 and via a blow-in connection 22 into a dust collection box 21 .

[0036] The discharge connection 20 carries an injection connection 22 of a dimensionally stable dust box 21 fixed at one end. Dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com