Systems and methods for fiber placement inspection during fabrication of fiber-reinforced composite components

An inspection method and fiber technology, applied in image enhancement, instrumentation, image data processing, etc., can solve problems such as weakening of composite parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0146] Clause 1. An inspection method, said inspection method comprising:

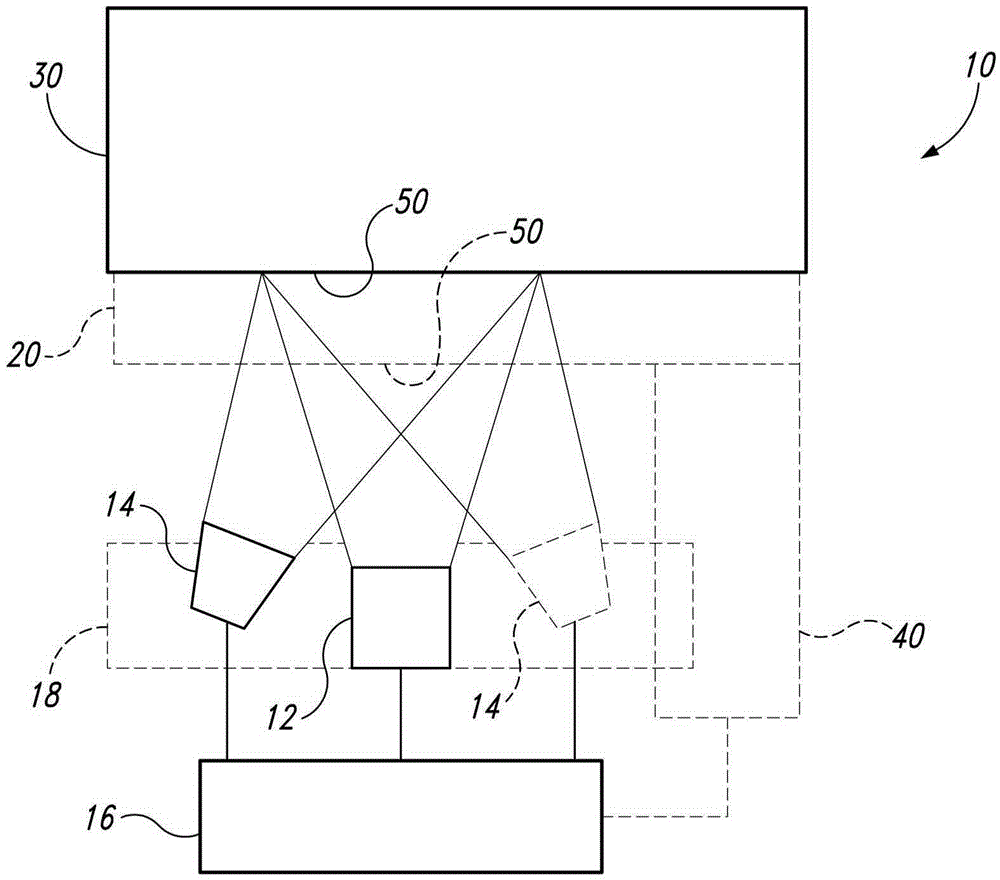

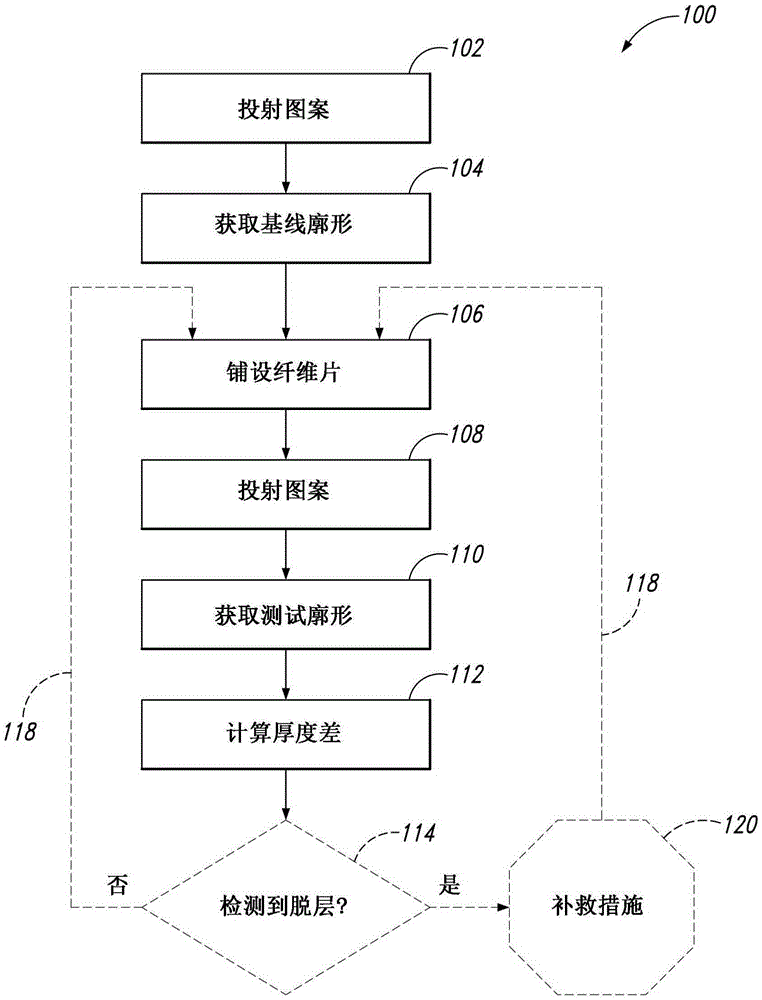

[0147] projecting 102 a light pattern onto the inspection area on the form 30;

[0148] acquiring 104 a baseline 3D profile of the forming part by imaging the light pattern on the forming part;

[0149] laying 106 an uncured fiber sheet onto the form in the inspection area;

[0150] projecting 108 the light pattern onto the uncured fiber sheet on the form;

[0151] acquiring 110 a test 3D profile of the uncured fiber sheet on the form by imaging the light pattern on the uncured fiber sheet on the form; and

[0152] A thickness difference between the test 3D profile and the baseline 3D profile is calculated 112 .

[0153] Clause 2. The inspection method of clause 1, wherein the step of obtaining 104 said baseline 3D profile and obtaining 110 said test 3D profile comprises performing digital image correlation.

[0154] Clause 3. The inspection method according to any one of clauses 1-2, further compr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap