A kind of edge banding technology of honeycomb panel

A technology of honeycomb panels and panels, which is applied in the field of panel edge sealing, which can solve the problems of not very high sticking firmness, falling off, and incapable of secondary molding, etc., to achieve a completely more stable edge sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

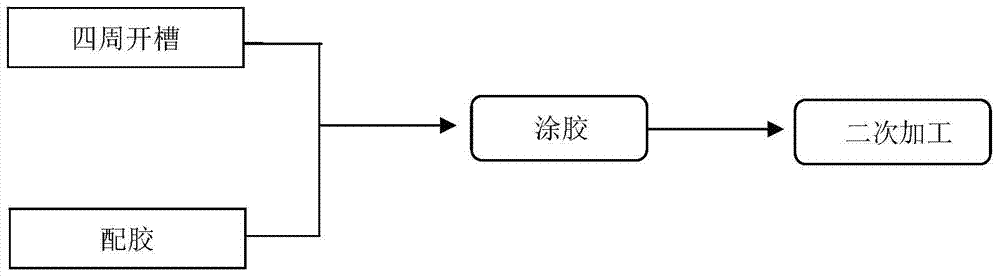

[0014] With reference to Fig. 1, preferred embodiment 1 of the present invention provides a kind of edge banding process of honeycomb panel, comprises the following steps:

[0015] a. Grooving: use a milling machine to mill out the honeycomb cores on the four sides of the honeycomb panel, that is, mill out a groove with a depth of 10mm;

[0016] b. Prepare edge sealant: mix epoxy resin and curing agent evenly according to the ratio of 2:1 to make edge sealant;

[0017] c. Glue filling: evenly fill the grooves around the honeycomb panel with the prepared edge sealant, and smooth the outer surface of the edge sealant with a spatula;

[0018] d. Secondary processing and forming: After the edge sealing adhesive is completely cured, use a milling machine to fine-mill the edge sealing edge, and perform secondary molding processing on the edge sealing adhesive around the honeycomb panel, and mill the uneven and non-smooth part of the edge sealing edge Lose.

[0019] In this embodim...

Embodiment 2

[0021] Preferred embodiment 2 of the present invention provides a kind of edge banding process of honeycomb plate, comprises the following steps:

[0022] a. Grooving: use a milling machine to mill out the honeycomb cores on the four sides of the honeycomb panel, that is, mill out a groove with a depth of 12mm;

[0023] b. Prepare edge sealant: mix epoxy resin and curing agent evenly according to the ratio of 5:2, then add 5-8% polystyrene of the total weight of epoxy resin and curing agent, and add polystyrene and polychloride at the same time. The defoamer with the same amount of ethylene is mixed evenly to make edge sealant; wherein, the curing agent is any one or a mixture of imidazoline and phenolic curing agents, and the defoamer adopts polyether Class defoamer.

[0024] c. Glue filling: evenly fill the grooves around the honeycomb panel with the prepared edge sealant, and smooth the outer surface of the edge sealant with a spatula;

[0025] d. Secondary processing and...

Embodiment 3

[0028] Preferred embodiment 3 of the present invention provides a kind of edge banding process of honeycomb plate, comprises the following steps:

[0029] a. Grooving: use a milling machine to mill out the honeycomb cores on the four sides of the honeycomb panel, that is, mill out a groove with a depth of 5mm;

[0030] b. Prepare edge sealant: mix epoxy resin and curing agent evenly according to the ratio of 5:2, then add 5-8% polystyrene of the total weight of epoxy resin and curing agent, and add polystyrene and polychloride at the same time. The defoamer with the same amount of ethylene is mixed evenly to make edge sealant; wherein, the curing agent is any one or a mixture of imidazoline and phenolic curing agents, and the defoamer adopts polyether Class defoamer.

[0031] c. Glue filling: First, apply a layer of polyurethane adhesive evenly on the outer surface of the groove, and then evenly fill the groove around the honeycomb panel with the prepared edge sealant, and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com