Electric balance car

An electric balance car and pedal technology, applied in the electromechanical field, can solve problems such as easily damaged axles, damage to load-bearing base components, safety issues, etc., and achieve the effects of improving comfort, protecting axles, components and personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

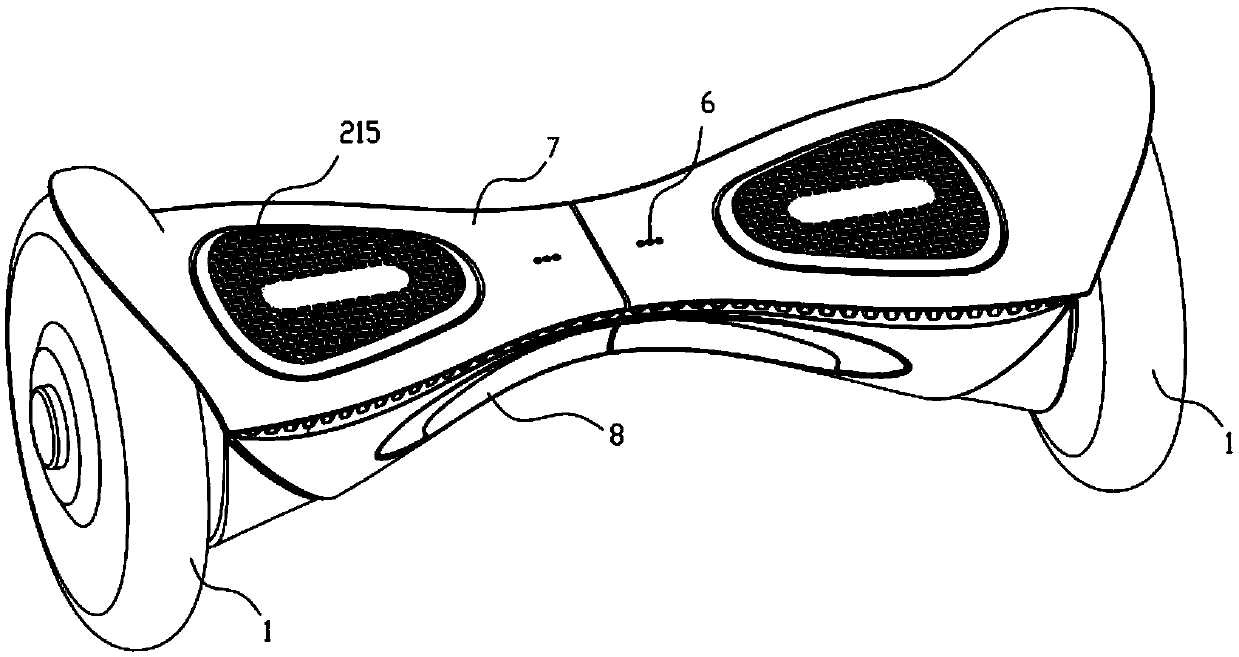

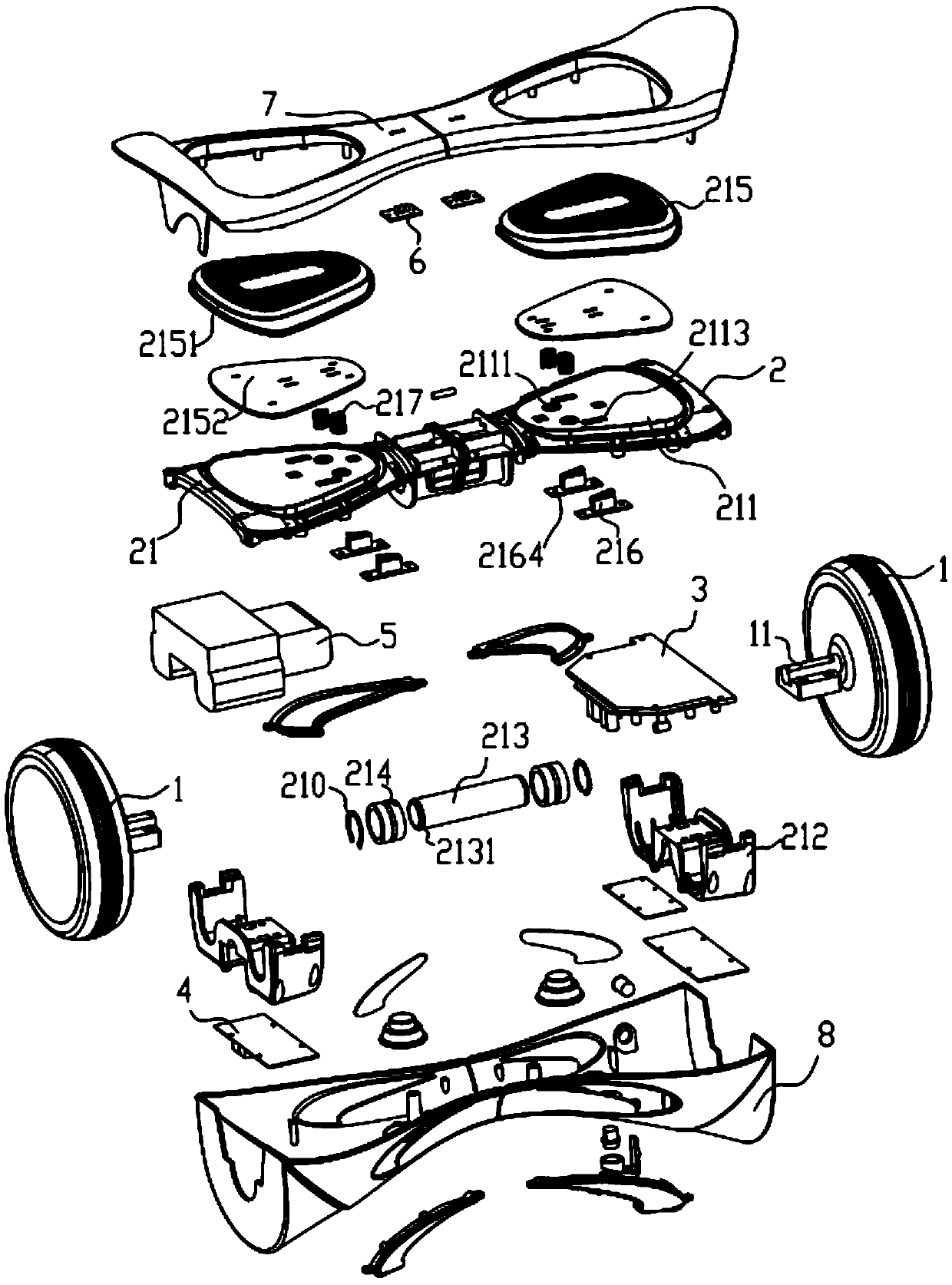

[0039] This embodiment provides an electric balancing car, which is mainly a two-wheel electric self-balancing twisting car.

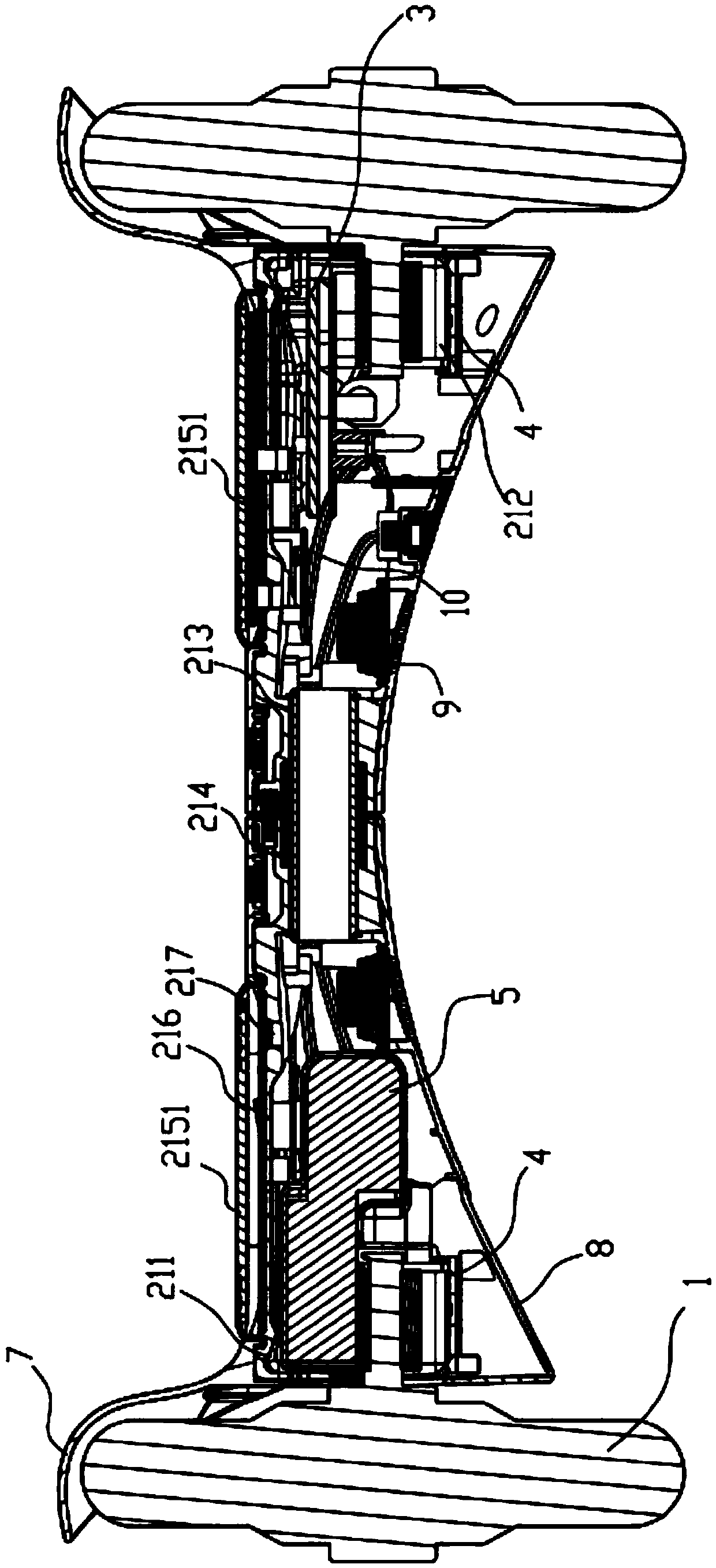

[0040] like Figure 1-3As shown, the electric balance car mainly includes: a wheel assembly 1 with a wheel shaft 11 and a pedal system 2 . The wheel assembly 1 is a hub motor. The pedal system 2 includes: two pedal assemblies 21 , and each pedal assembly 21 is correspondingly assembled with one wheel assembly 1 . The pedal assembly 21 includes: a load-bearing base 211 and a suspension frame 212 . Among them, such as Figure 4-5 As shown, the suspension frame 212 includes: a support portion 2121 abutted against and fixed to the wheel shaft 11, a force receiving portion 2122 assembled with the load-bearing base 211 and separately arranged on both sides of the axial projection line of the wheel shaft 11 on the load-bearing base 211, And, the connecting portion 2123 located between the supporting portion 2121 and the force receiving portion 2122 . The...

Embodiment 2

[0054] The difference between this embodiment and the foregoing embodiments mainly lies in: the structure of the suspension frame 212 is different. That is to say, in this embodiment: from the load-bearing base 211 to the suspension frame 212, the cross section of the combination part 2100 of the force receiving part 2122 and the connecting part 2123 along the radial direction of the wheel shaft 11 is arc-shaped, and the support part 2121 is along the radial direction of the wheel shaft 11. The cross-section is annular, and the outer surface of the support part 2121 is in contact with the inner surface of the combination part 2100, as Figure 12 shown. or, as in Figure 13 As shown, the outer surface of the support part 2121 is in contact with the outer surface of the combination part 2100, and the suspension frame 212 includes: a fifth force receiving part and a sixth force receiving part assembled with the load-bearing base 211 and arranged on one side of the projection lin...

Embodiment 3

[0056] The difference between this embodiment and the above-mentioned embodiments mainly lies in: the setting position of the micro switch 216 is different. That is to say, in this embodiment: the switch base 2161 is fixed on the footrest 215 , the fixed part of the action reed 2162 is fixed to the footrest 215 , and the free part can abut against the load-bearing base 211 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com