Emulsion pump with closure between pressing head and locking cover improved

A lotion pump and lock cover technology, which is applied in the field of lotion pumps, can solve the problems of poor self-locking performance between the liquid inlet channel and the lock cover, and easy misoperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

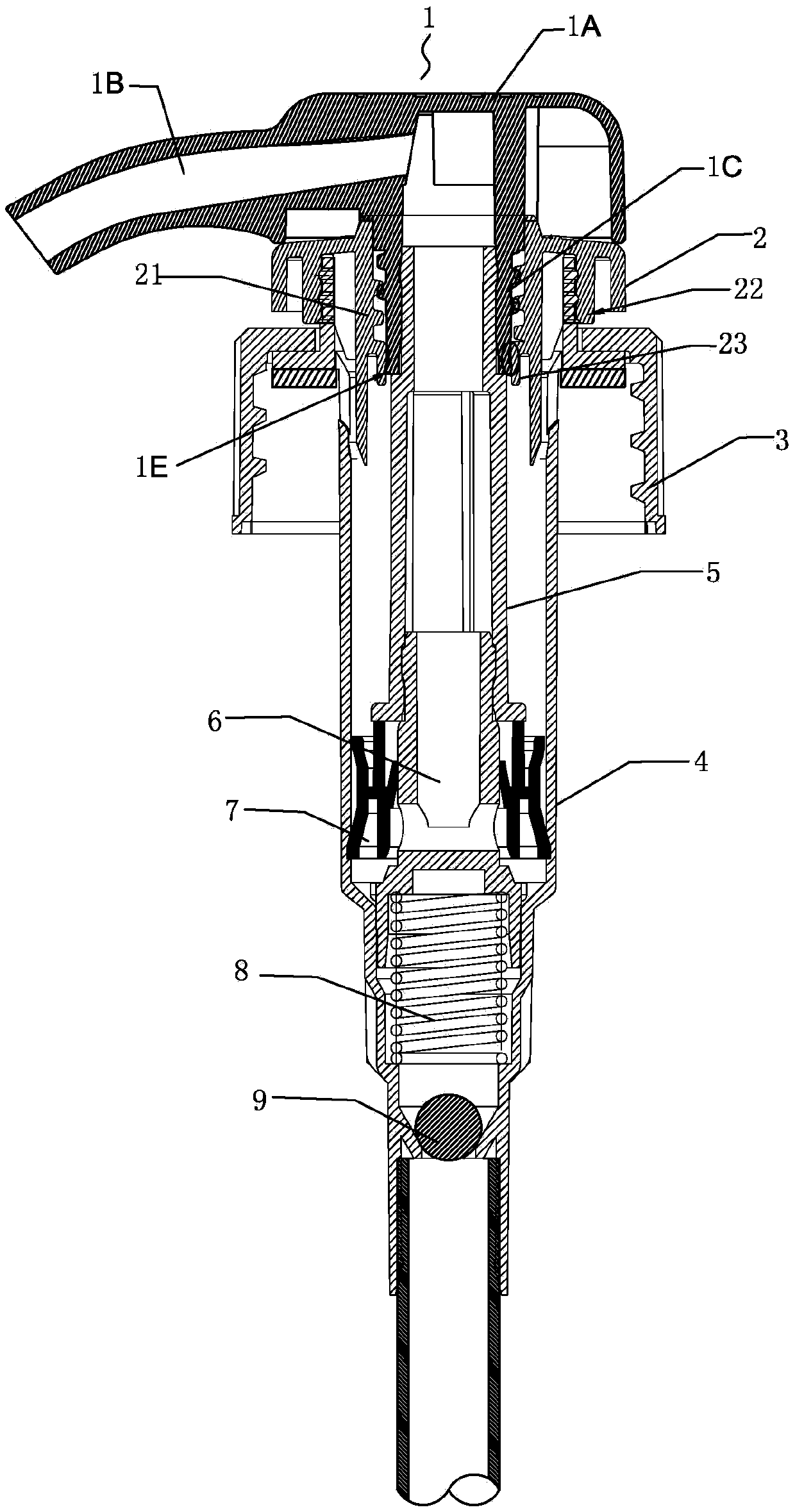

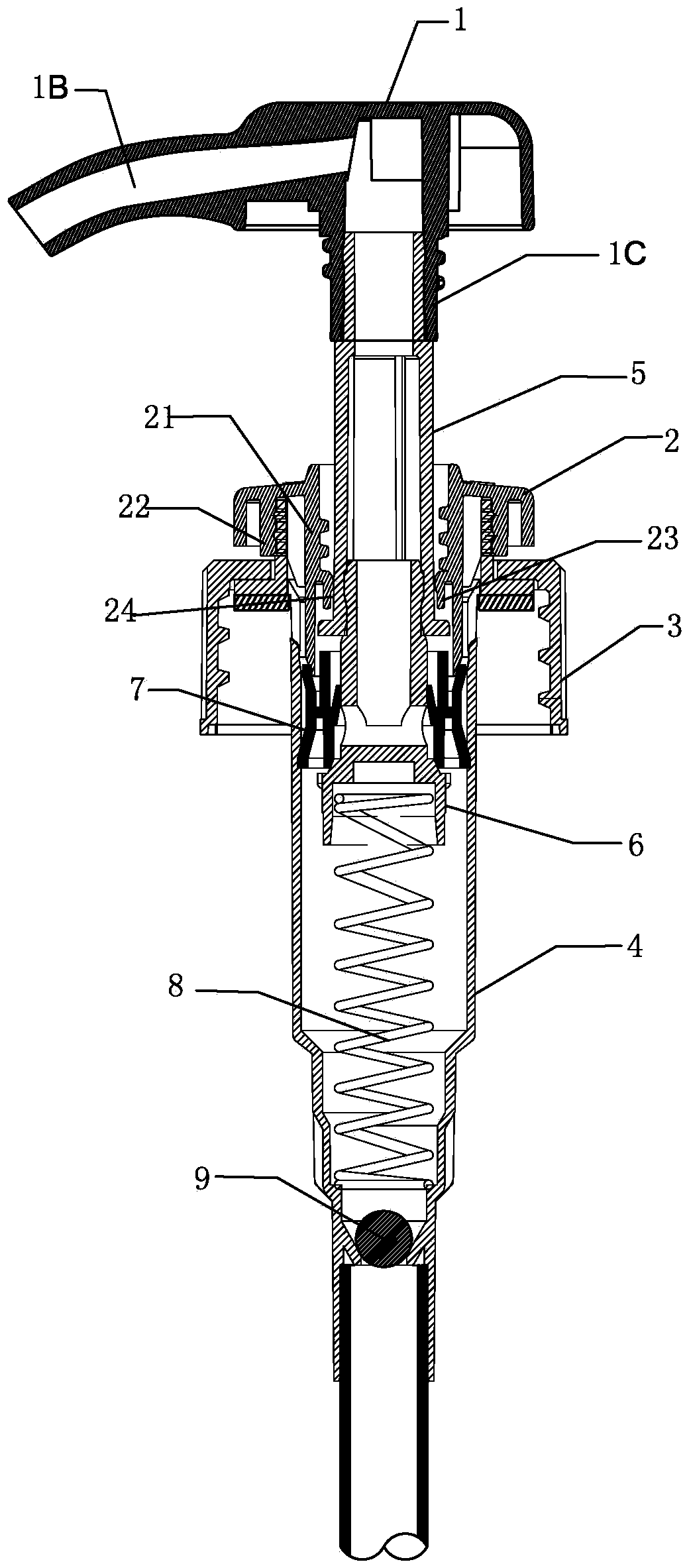

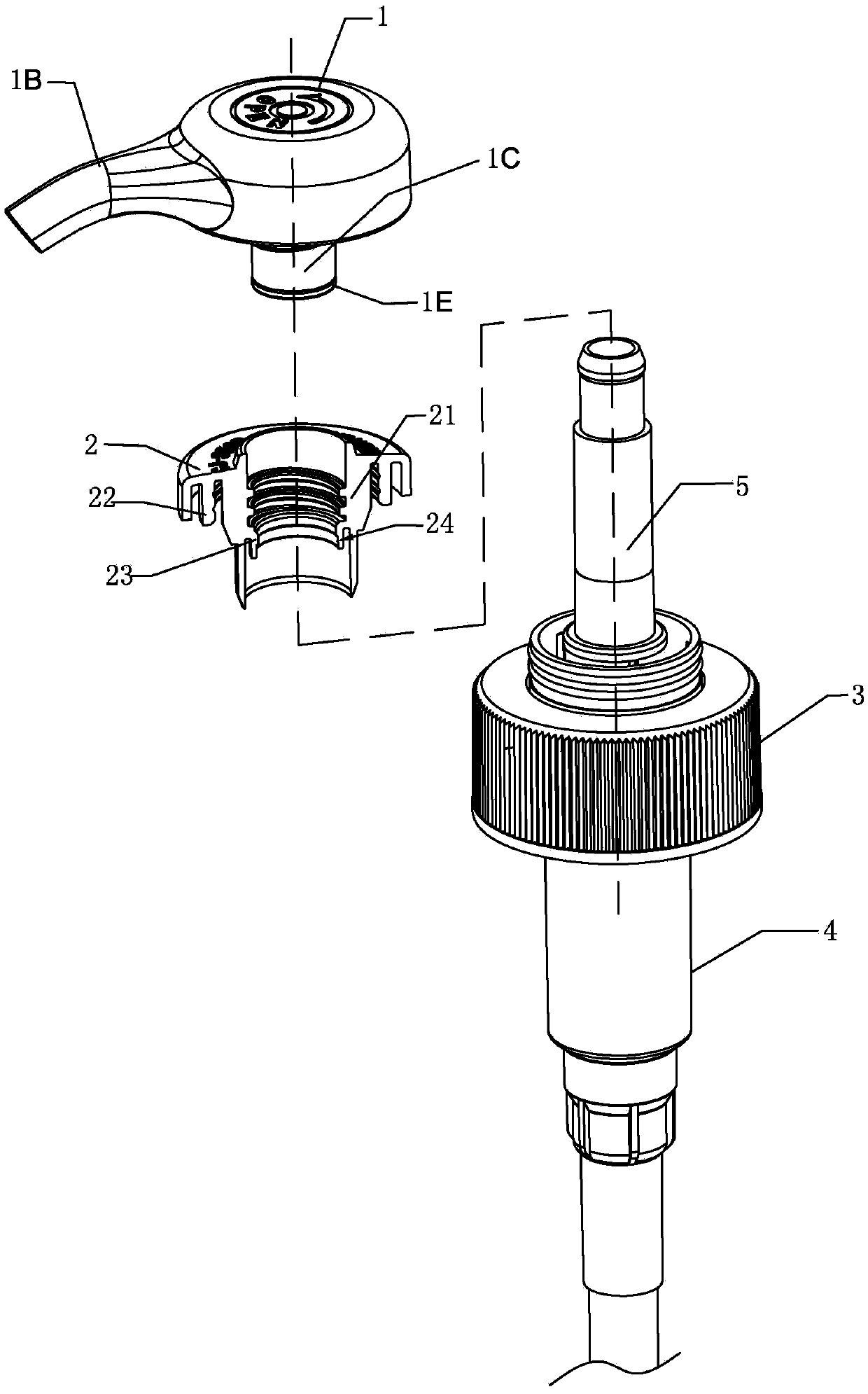

[0029] Such as figure 1 , figure 2 As shown, a lotion pump with an improved locking head and lock cover, including a press head 1, a lock cover 2, a thread 3, a body 4, a main post 5, an auxiliary post 6, a piston 7, a spring 8 and a glass ball 9 The press head 1 includes a base 1A, a liquid outlet nozzle 1B and a liquid inlet channel 1C, and the liquid inlet channel 1C communicates with the liquid outlet nozzle 1B; the lock cover 2 includes a guide sleeve 21 at the center and an internal thread interface 22 surrounding the guide sleeve; The upper end of the body 4 passes through the thread 5 and is screwed to the internal thread interface of the lock cover 2 , the liquid inlet channel 1C of the press head 1 is connected to the upper end of the main column 5 , and the press head 1 is detachably connected with the lock cover 2 .

[0030] The press head 1 is provided with a locking device;

[0031] The guide sleeve 21 of the lock cover 2 has a single-head internal thread, and...

Embodiment 2

[0041] Such as Figure 4 As shown, there are several axial grooves 1F located on the lower part of the single-head external thread on the liquid inlet channel 1C; the axial grooves 1F have radial openings and lower end openings;

[0042] The guide sleeve 21 of the lock cover 2 has several teeth 25 located at the lower part of the single thread;

[0043] The teeth 25 cooperate with the axial groove 1F. When the push head rotates relative to the lock cover, the tooth 25 is in sliding fit with the axial groove 1F.

[0044] As a further improvement: the lower end of the guide sleeve of the lock cover is provided with a cylindrical seat 26 , and the teeth 25 are arranged on the inner wall of the cylindrical seat 26 .

Embodiment 3

[0046] Such as Figure 5 , Figure 6 As shown, the locking device includes a cylindrical interface 1D surrounding the liquid inlet channel 1C and a single-head thread arranged on the cylindrical interface;

[0047] The lower end of the cylindrical interface 1D is provided with an axial groove 1F, and the lower end of the guide sleeve 21 is provided with several teeth 25;

[0048] The single-start thread of the cylindrical interface 1D is screwed with the single-start thread on the guide sleeve 21, and the teeth 25 cooperate with the axial groove 1F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com