A wave-wheel washing machine with a washing ball disc

A pulsator washing machine and washing ball disc technology, which is applied in the field of washing machines, can solve the problems of affecting the degree of cleanliness, the deviation of the rotation of the washing tub, and the intertwining of clothes, so as to reduce the intertwining of clothes, improve the washing effect, and shorten the washing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

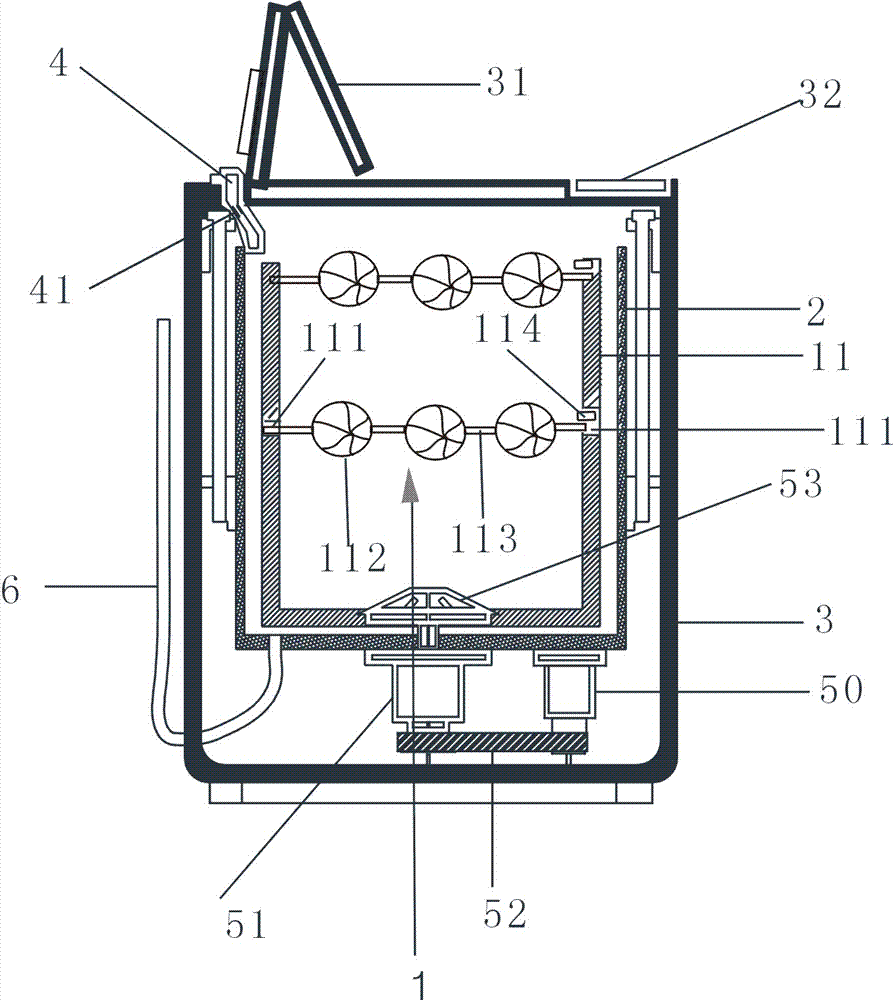

[0019] Figure 1-5 , a pulsator washing machine with a washing ball disc, comprising a water tub 2, an outer box body 3, a water inlet 4, a drain pipe 6, a washing tub 11, an upper cover 31, a control panel 32, a motor 50, a reducer 51, and a transmission belt 52, pulsator 53. This is the existing technology, so it will not be described in detail.

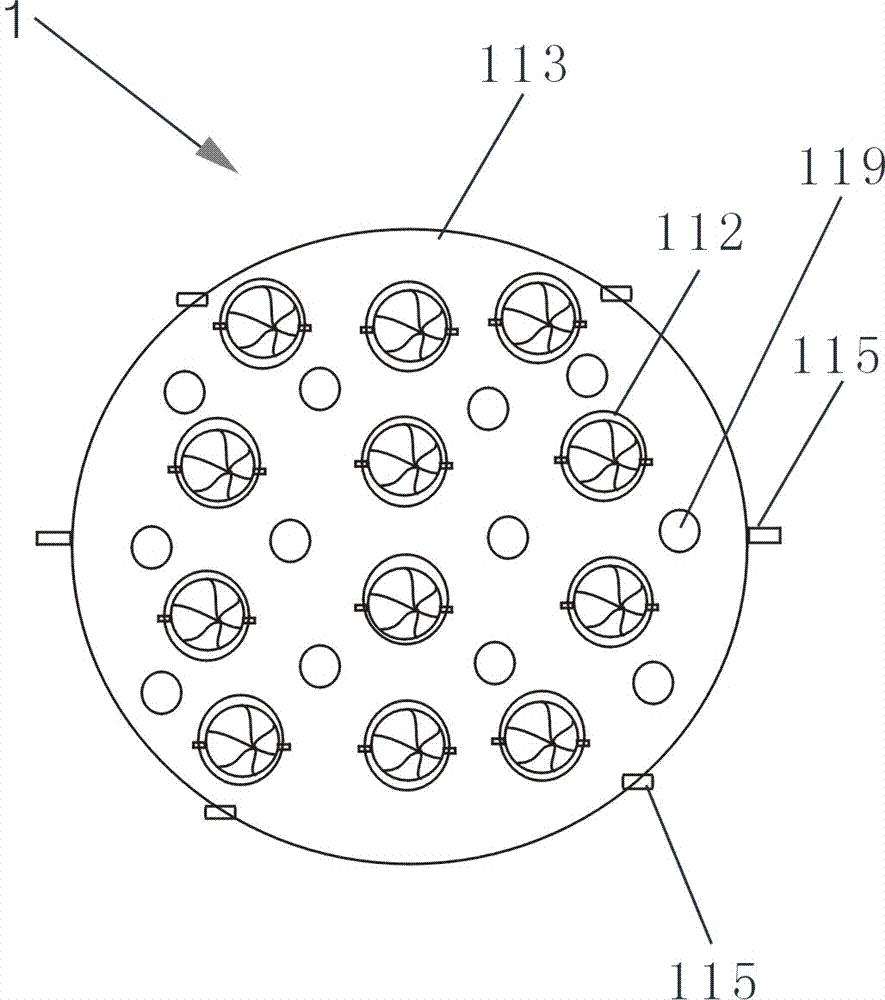

[0020] The washing bucket 11 is provided with a washing ball tray 1 , and the washing ball tray 1 includes a plurality of washing balls 112 , a disc holder 113 , and a fixing member 115 . The washing ball 112 is installed in the disc hole 116 of the disc holder 113, and the washing ball can rotate. The fixing member 115 is disposed on the periphery of the disk frame 113 .

[0021] There is a groove 111 on the inner wall of the washing bucket 11, and a buckle 114 is arranged above the groove 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com