Spherical pair centering and one-dimensional calibration target for automobile topography visual detection system

A technology of visual inspection and spherical pair, which is used in measuring devices, instruments, and optical devices, etc., to achieve the effects of large output, few machining processes, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

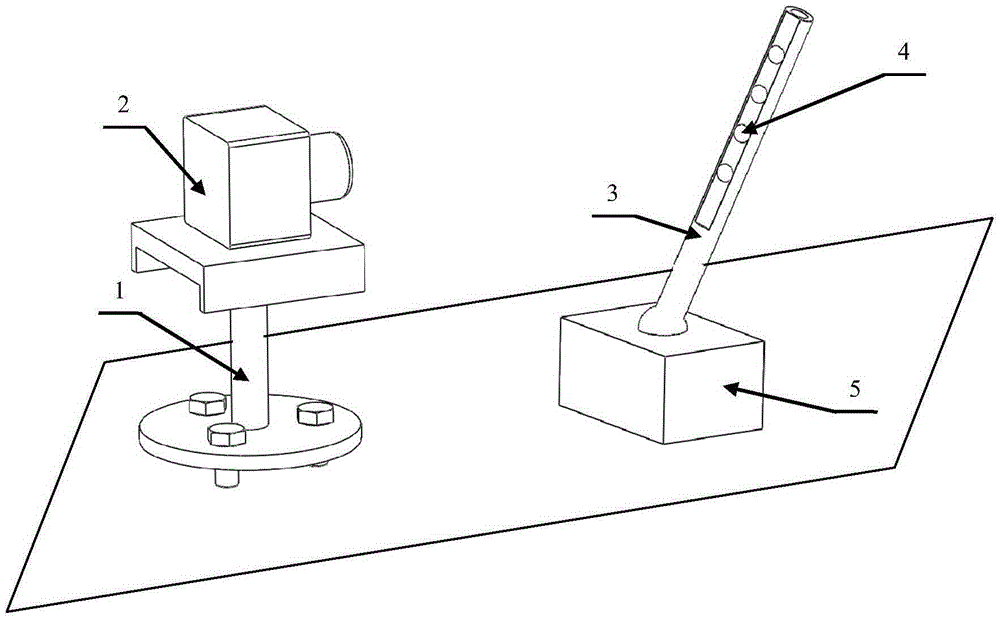

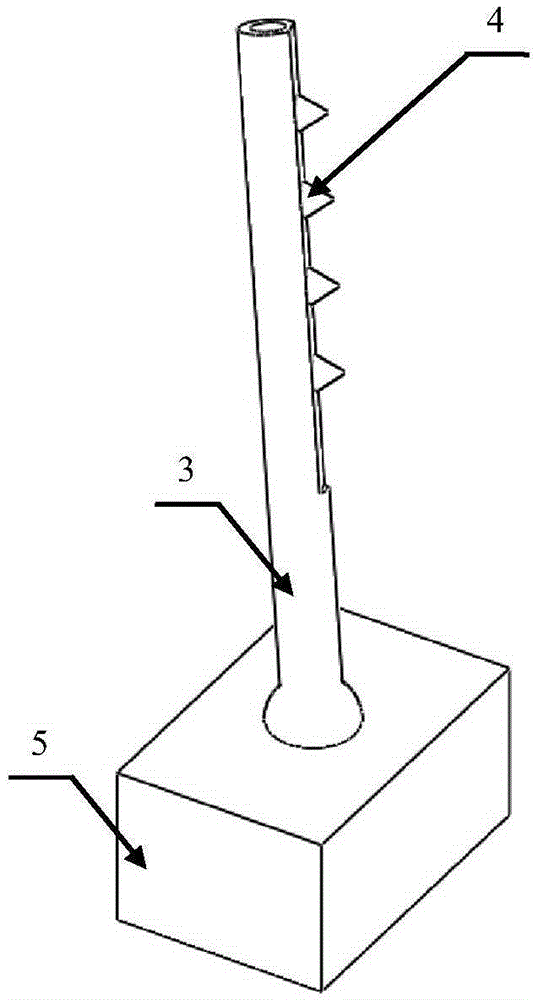

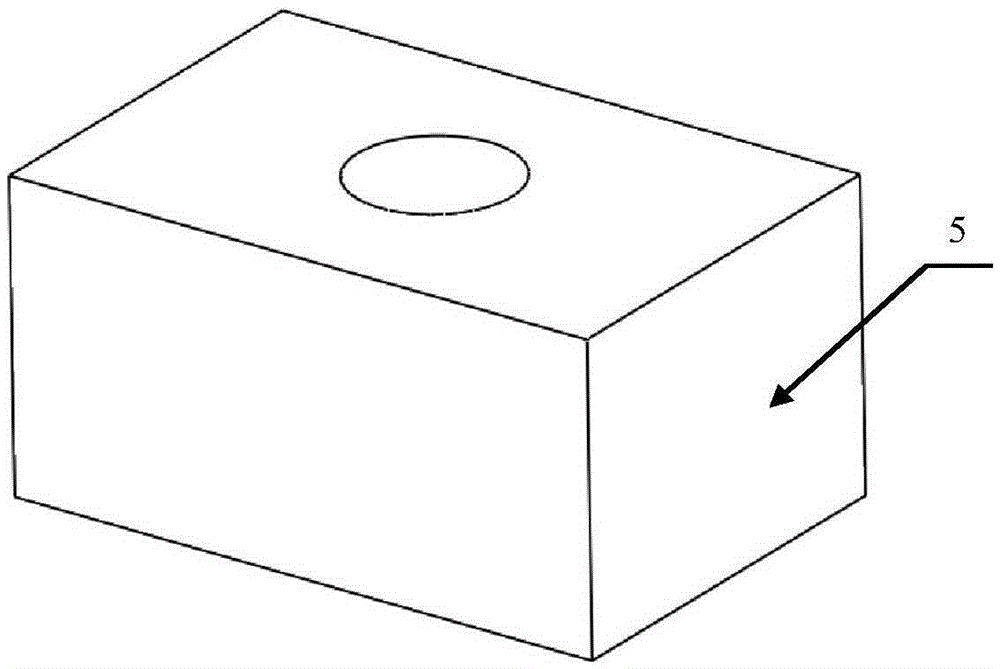

[0018] refer to Figure 1 to Figure 3 , the spherical sub-centering one-dimensional calibration target of the automobile topography visual inspection system includes a camera bracket 1 , a camera 2 , a spherical sub-type target rod 3 , a conical target 4 and a base 5 .

[0019] The camera bracket 1 is welded by thin steel plate, steel pipe and circular steel plate. The circular steel plate at the bottom is uniformly processed with three circular through holes. The bolts pass through the three circular through holes of the circular steel plate of the camera bracket 1 and are fixedly connected to the ground A steel pipe is welded in the middle of the upper surface of the circular steel plate, and a thin steel plate bent on both sides is welded on the top surface of the steel pipe.

[0020] The camera 2 is placed in the middle of the thin steel plate at the top of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com