Thermal power set DCS analog quantity control circuit simulation test system and method

A DCS system and analog control technology, applied in simulators, general control systems, control/regulation systems, etc., can solve problems such as affecting the effect of functional testing, limited algorithms, and backwardness, so as to improve the quality of configuration work and improve implementation. quality effect

Active Publication Date: 2016-03-02

SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Both of these two methods have shortcomings. The first method can only realize simplified simulation and rough simulation of the control object due to the complexity and diversity of the object model and the limited algorithm provided by the configuration tool, which affects the effect of functional testing.

In the second method, the engineering unit does not necessarily have a simulation model. Even if the simulation model is built, it often lags behind the DCS system, and it is time-consuming and laborious to establish all links (thousands of signals) with the simulation model, and the simulation cannot be completed before the DCS on-site commissioning. test

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

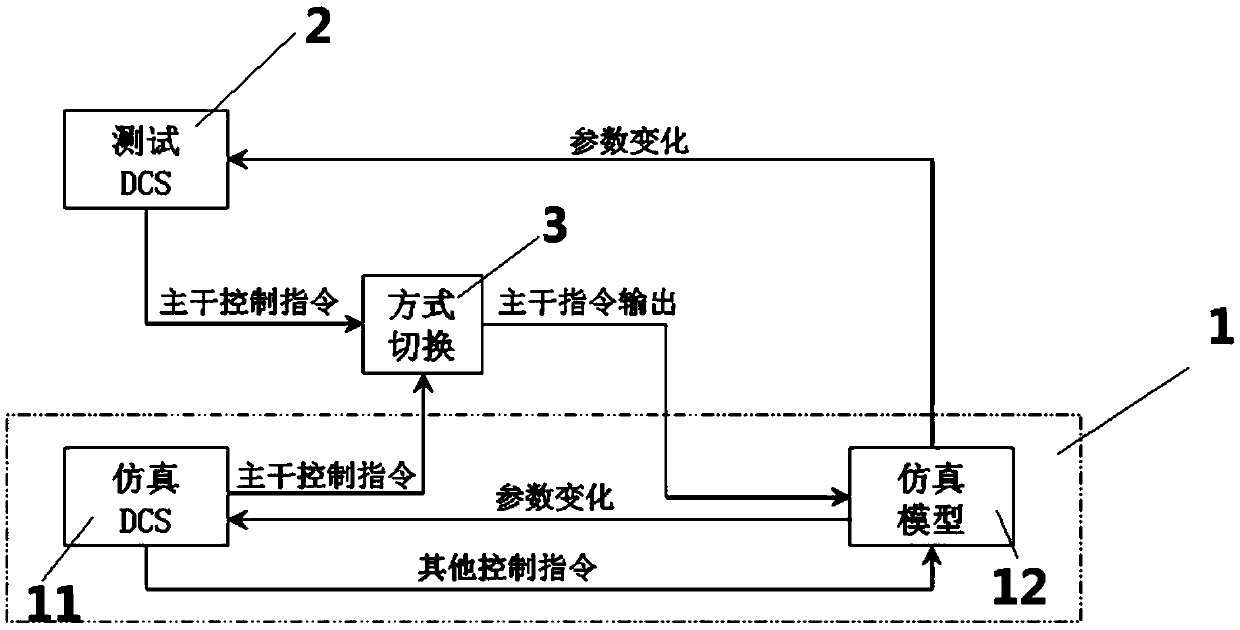

The invention relates to a thermal power set DCS analog quantity control circuit simulation test system and method. The system comprises a thermal power set excitation type simulation platform and a test DCS, wherein the thermal power set excitation type simulation platform comprises a simulation DCS and a simulation model which are mutually connected, and the test DCS and the simulation model employ trunk connection; and the test DCS sends a trunk control instruction to the simulation model, and after operation of the simulation model, simultaneously sends control parameters to the test DCS and the simulation DCS so as to realize a control closed loop. Compared to the prior art, the system and method provided by the in invention have the following advantages: a dynamic simulation test of an analog quantity loop is realized, the problems existing in logic configuration are discovered and solved timely, the implementation quality of control function configuration is improved, favorable conditions are created for control of actual system debugging and smooth application, and the like.

Description

technical field The invention relates to the field of automatic control of a thermal power generating set, in particular to a simulation test system and method for a DCS system analog quantity control loop of a thermal power generating set. Background technique The analog quantity control loop in the DCS system of thermal power units mainly realizes the automatic adjustment and control function of unit operating parameters, from the control of water level, flow, and speed control at the bottom to the control of parameters such as steam temperature, steam pressure, and power generation load at the upper layer, and also includes auxiliary equipment. Control functions such as rapid load reduction in case of equipment failure. Whether these control functions can be implemented correctly will often affect the safe and normal operation of the unit, so an effective functional test should be carried out before the DCS system leaves the factory. But at this time, the DCS system has ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B17/02

CPCG05B17/02

Inventor 祝建飞沈丛奇姚峻归一数沈建峰王松邱寅祺

Owner SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com