On-load tap changer, method for installing load transfer switch insert in on-load tap changer, and kerosene drain screw

A technology of on-load tap-changing and switching, which is applied in the direction of electric switches, pipes/pipe joints/pipe fittings, pipe components, etc. It can solve the problems of large time consumption, inconvenient special wrench, impracticality, etc., and achieve the effect of simple inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

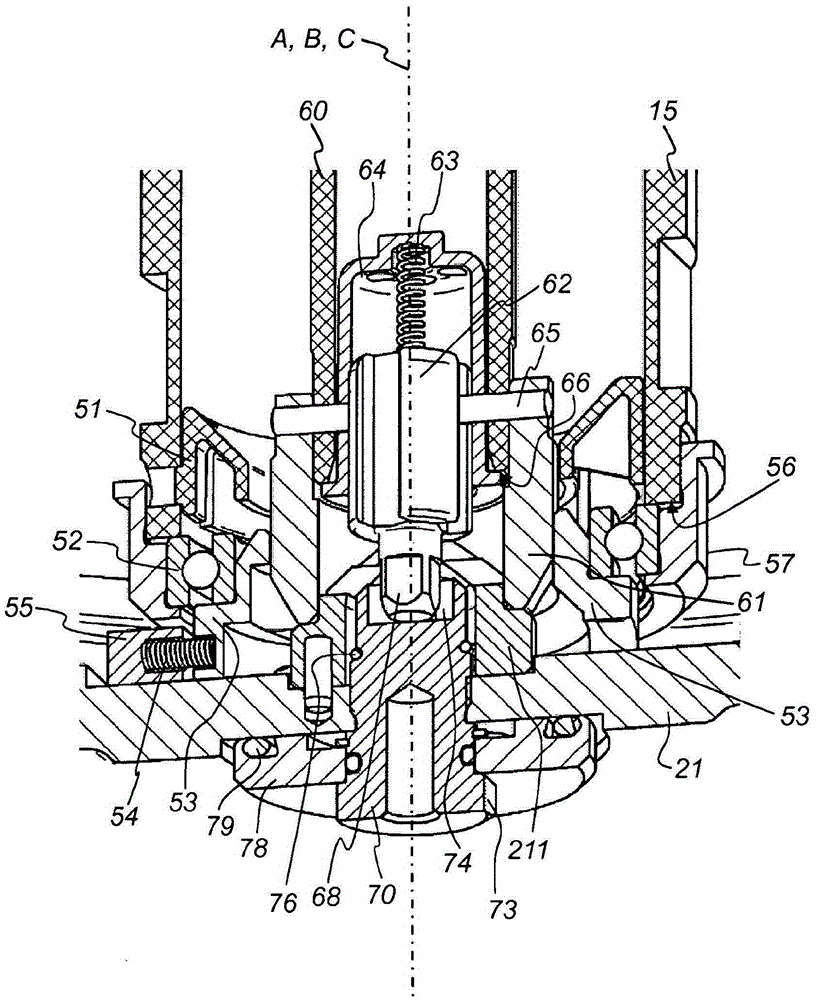

[0044] The same reference numerals are used for identical or identically acting elements of the invention. Furthermore, for the sake of clarity, only the reference numerals necessary for describing the respective figure are shown in the individual figures. The embodiment shown only constitutes an example of how the on-load tap changer according to the invention and the kerosene drain plug according to the invention can be constructed and therefore does not constitute a final limitation of the invention.

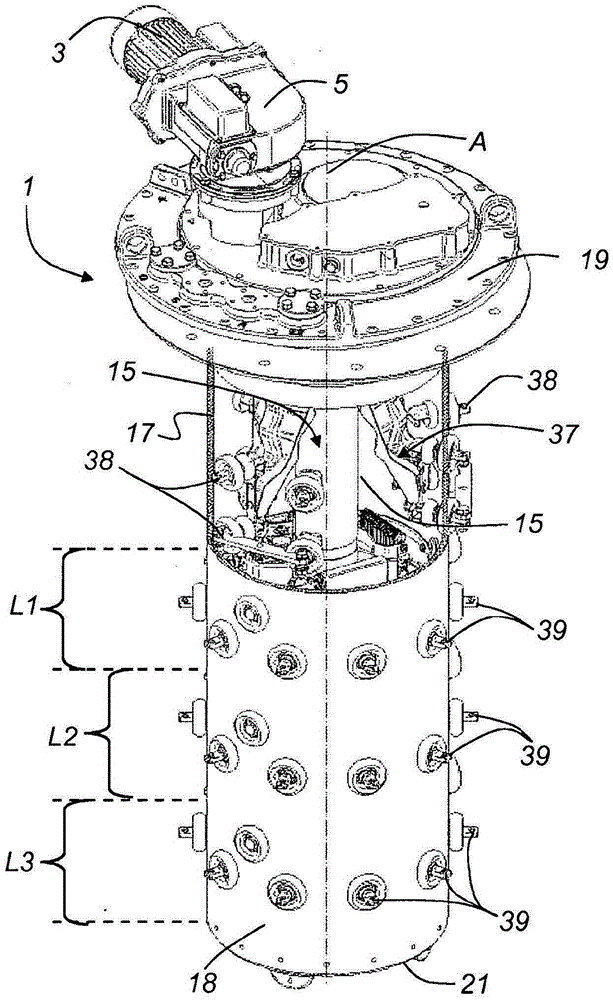

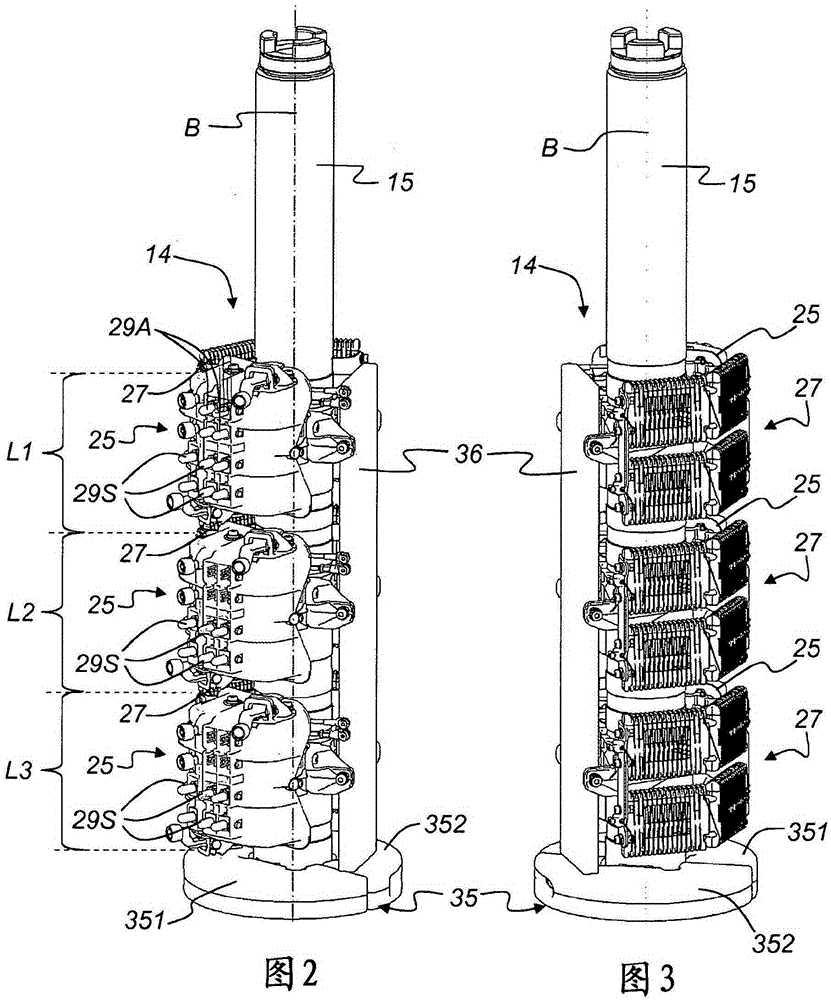

[0045] figure 1 A perspective view of an embodiment of the on-load tap-changer according to the invention in the form of a three-phase on-load tap-changer or on-load selector 1 is shown. The on-load selector 1 has a drive 3 , for example an electric motor, with a transmission 5 , which pulls up a force store (not shown).

[0046] If the force accumulator is fully pulled up, ie tensioned, it is unlocked, its energy is released suddenly and the switching line 15 of the on-loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com