Fuel gas calcination method for secondary starting of aluminum electrolytic bath

A technology of secondary startup and gas roasting, which is applied in the field of aluminum electrolysis production process, can solve the problem that the heating rate and the uniformity of temperature distribution cannot be effectively controlled, the cathode and lining of the motor groove are prone to cracks, and the electrolytic cell is installed with coke particles. Complexity and other problems, to avoid uneven heating, easy to popularize and use, and prevent filtrate leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

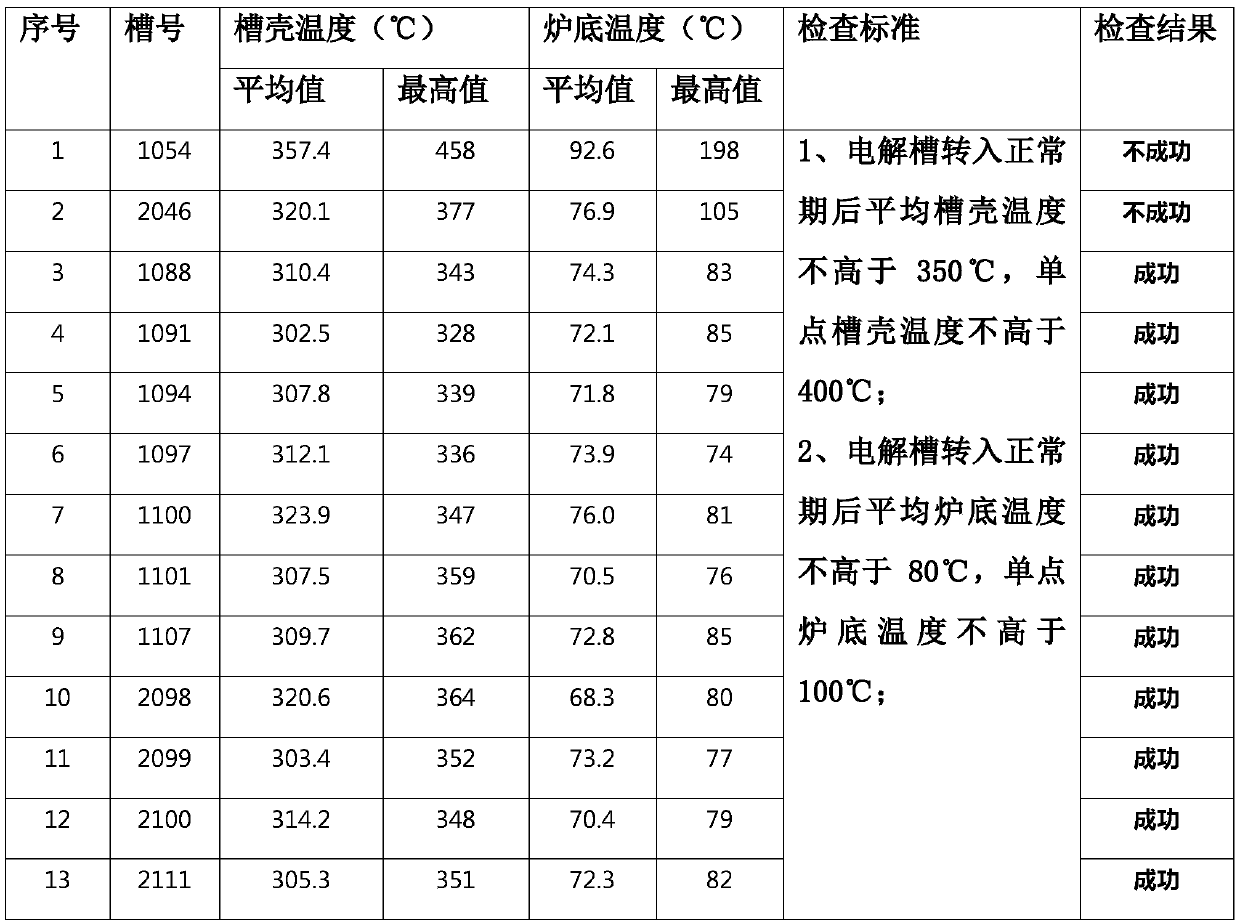

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

[0019] The gas roasting method for the secondary start-up of the aluminum electrolytic cell comprises the following steps:

[0020] ①Purge the chamber of the electrolytic cell first, and then fill the curved surface groove between two adjacent cathodes in the electrolytic cell with electrolyte fragments. The purpose of filling with electrolyte fragments is to reduce thermal shock and avoid The molten aluminum enters the cathode crack;

[0021] ②Select qualified anode carbon block, then install the anode carbon block on the boss of the cathode in the electrolytic cell, and then clamp the anode carbon block and the cathode with a small box clamp to prevent the anode from sliding down w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com