Butt-joint type garbage truck rear door opening and closing device

A technology of opening and closing device and garbage truck, applied in the directions of garbage receptacle, transportation and packaging, etc., can solve the problems of inability to rotate, high load of rotating shaft, difficult control of corner position, etc., and achieve the effect of shortening the linear stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

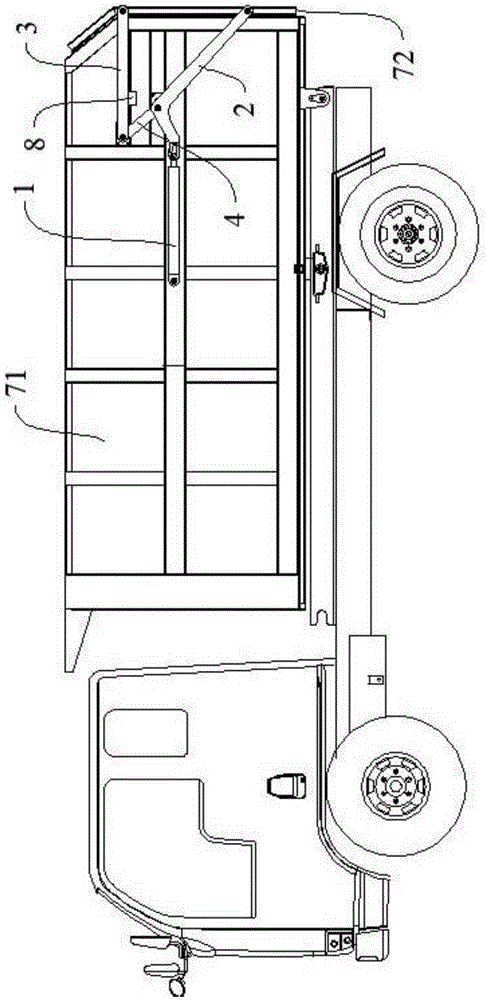

[0024] It should be noted that the rear door opening and closing devices of the docking garbage truck are always installed in pairs on the two side walls of the compartment. For the convenience of description, only one side is used as an example below.

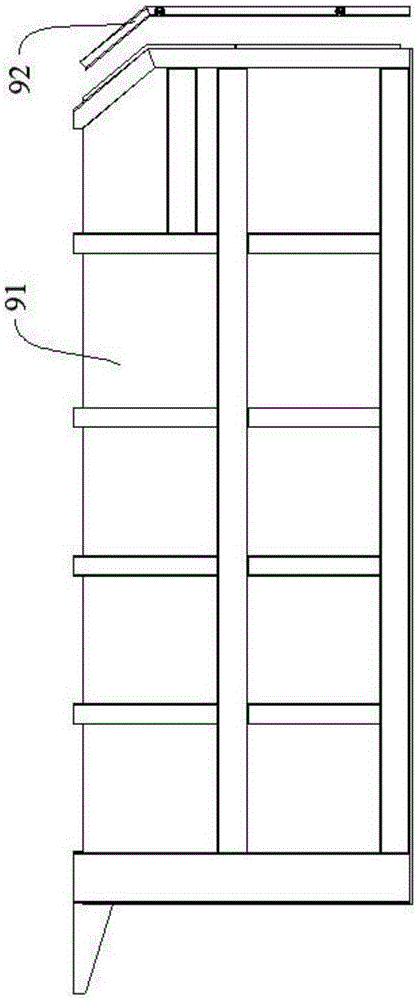

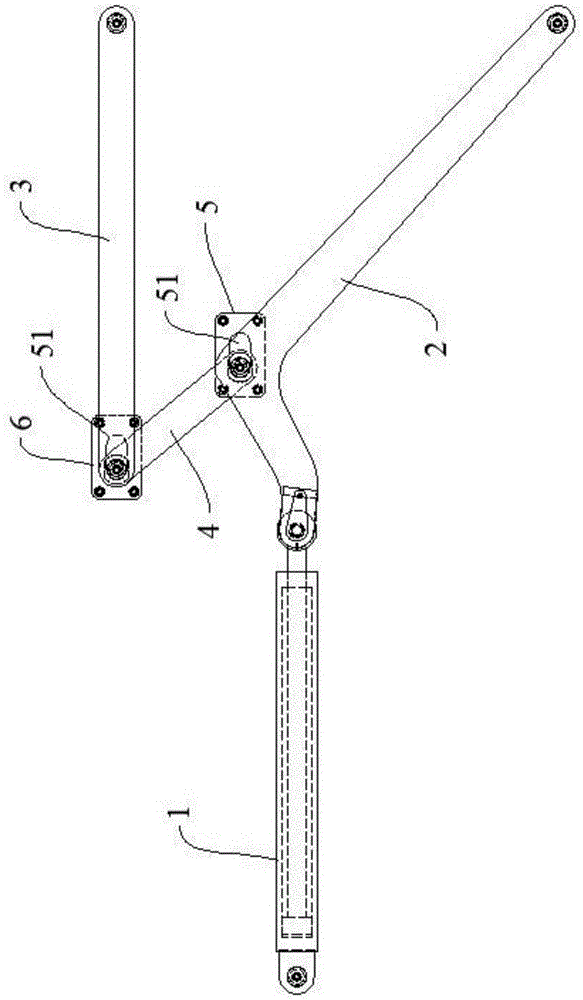

[0025] as attached Figure 2-7 As shown, a rear door opening and closing device of a docking garbage truck includes: a drive cylinder 1, a main arm 2, an auxiliary arm 3, a linkage arm 4, a first support seat 5, and a second support seat 6; wherein, the first support The seat 5 and the second support seat 6 are fixed on the side wall of the compartment assembly 7. The first support seat 5 is located obliquely below the second support seat 6 and close to the inlet and outlet of the compartment. The first support seat 5 and the second support seat 6 is provided with a waist-shaped groove 51, and a pin shaft 52 which can slide and pivot is arranged in the waist-shaped groove 51; 52 is hinged with the main arm 2 through the afore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com