Automatic locking device for tank cover of pressure tank

An automatic locking and pressure tank technology, applied in the field of pressure tanks, can solve the time-consuming and labor-intensive problems of opening and closing tank lids, and achieve the effects of reducing friction, locking fastness and stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

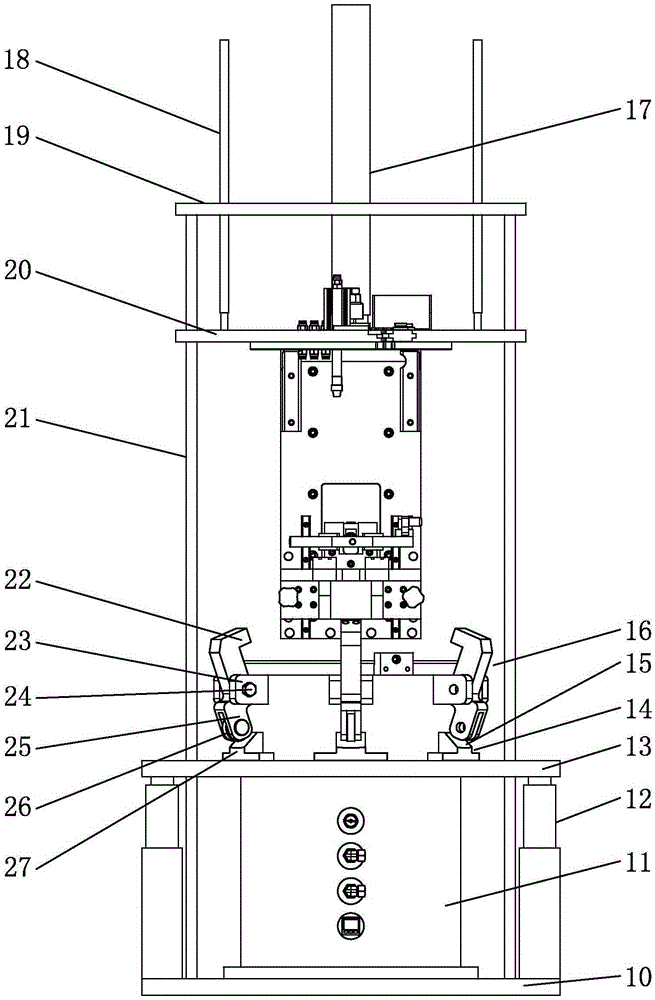

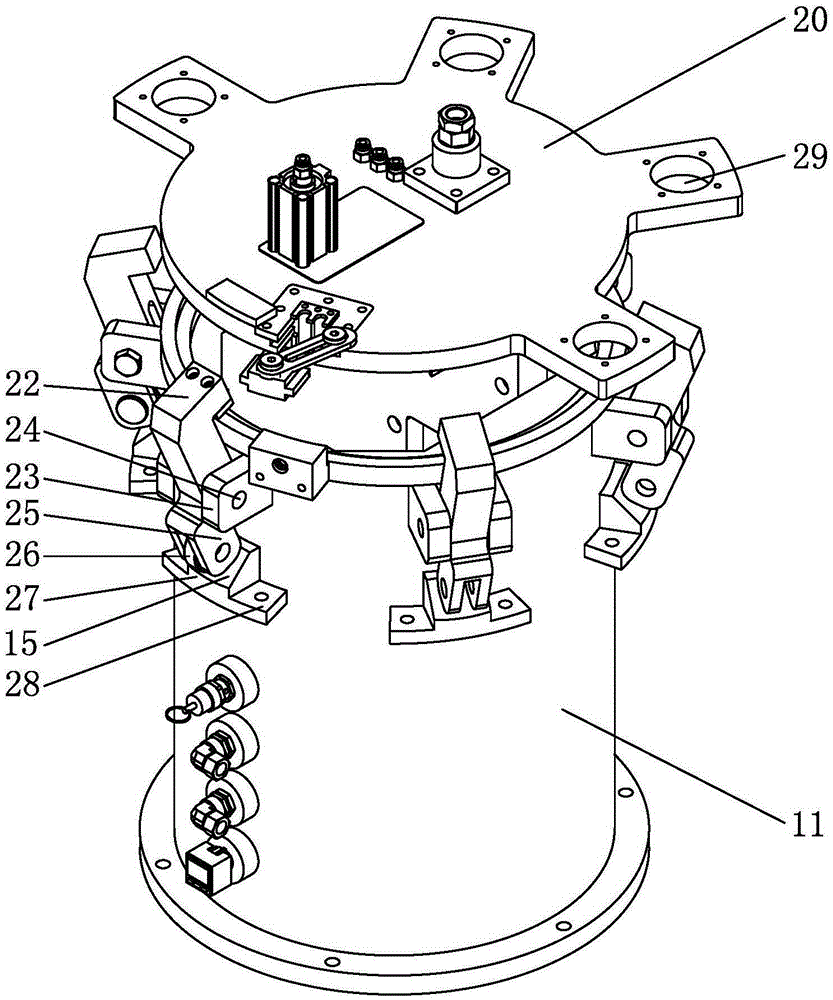

[0022] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — figure 2 :

[0023] The tank cover automatic locking device of the pressure tank includes the tank body 11 of the pressure tank and the tank cover 20 covering the opening of the tank body 11. The outer wall of the tank body 11 opening is provided with more than three fixing seats at intervals in the circumferential direction. 23, the hinge part of the middle part of the lock block 16 is hinged on the fixed seat 23 through the hinge shaft 24, the upper side of the lock block 16 has a lock hook 22, and the lower side has a drive arm 25, and the lock hook 22 of the lock block 16 is connected to the drive arm 25 and The hinge part in the middle is an integral structure, and the lower side of the driving arm 25 is provided with a driving ring 13 driven by a power device to move up and down and sleeved on the outer wall of the tank body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com