Uniformly distributed load booster device, three-dimensional slope failure model test device and method

A booster device and uniform load technology, applied in the direction of measuring device, using optical device, using stable tension/pressure test material strength, etc., can solve deviation, load is not uniform, can not provide theoretical basis for engineering design, etc. problem, to achieve the effect of precise theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

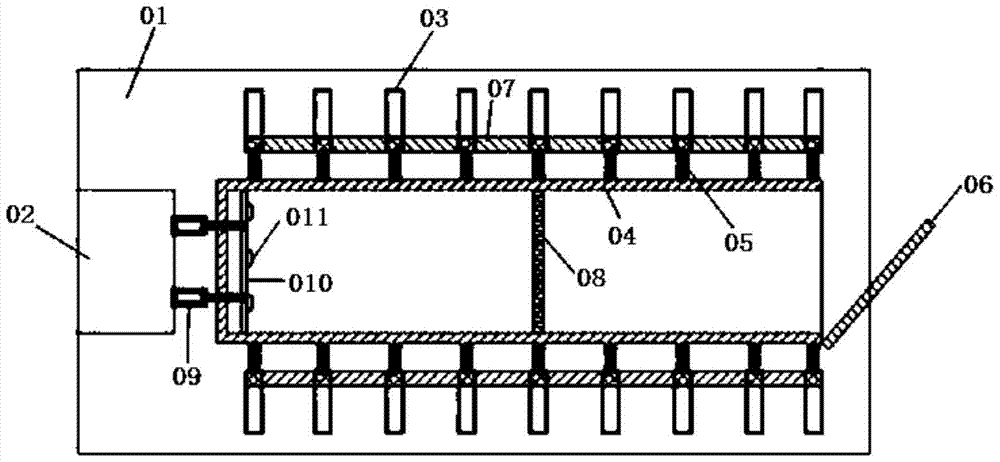

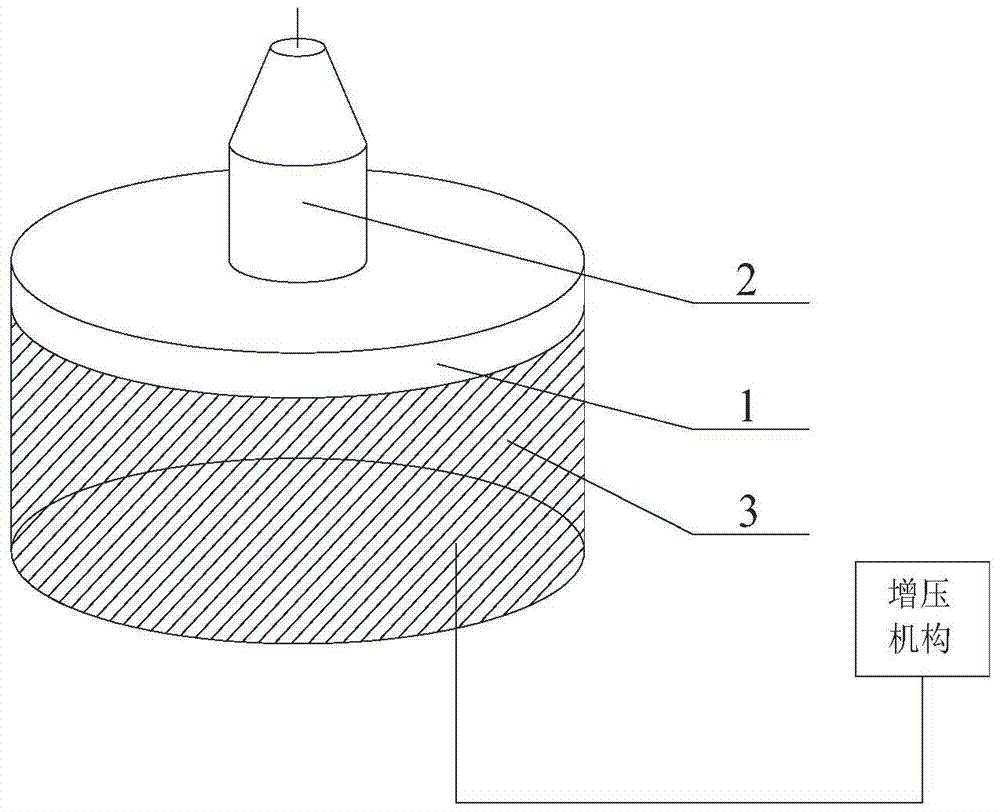

[0078] See attached image 3 , the uniformly distributed load supercharging device provided in Embodiment 1 of the present invention includes a flat plate 1, a force applying unit 2, and a supercharging mechanism. The force applying unit 2 is used to apply the force of the action point on the plate 1, and the plate 1 directly contacts the force The carrying object 3, the booster mechanism is used to increase the force that the carrying object 3 can exert externally.

[0079] When the uniformly distributed load supercharging device provided by Embodiment 1 of the present invention is applied, the action point of the force exerted by the force applying unit 2 is on the flat plate 1, through the transmission of the flat plate 1, and then by the bearing directly contacting the flat plate 1 When the load is applied to the object 3, the load can be evenly distributed, and when the force that can be applied to the load is increased by the uniform load booster device, the increased lo...

Embodiment 2

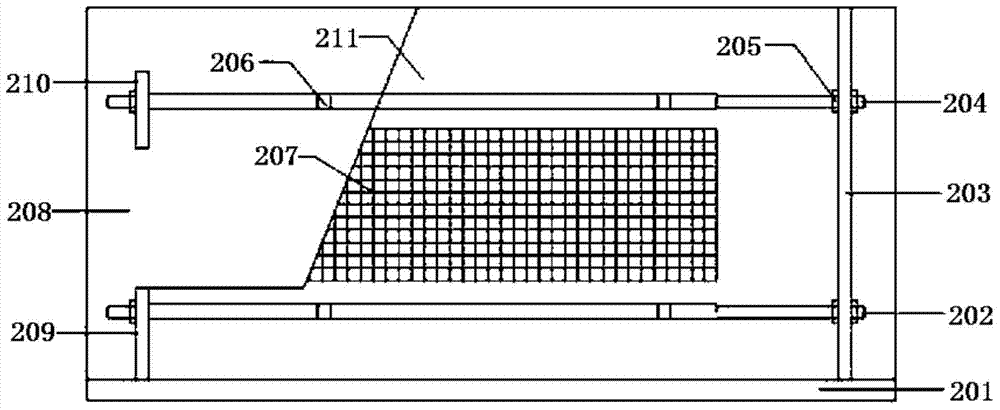

[0082] See attached Figure 5 , improve on the basis of the uniformly distributed load supercharging device provided in Embodiment 1 of the present invention, the uniformly distributed load supercharging device provided in Embodiment 2 of the present invention also includes a container 4, the container 4 has a side wall, and the plate 1 has a thickness, The inner cross-sectional shape of the container 4 is the same as the cross-sectional shape of the flat plate 1, and the inner wall of the flat plate 1 and the container 4 constitutes a sliding pair. In this case, the inner wall of the container 4 can form a constraint with the outer wall of the flat plate 1, so that the flat plate 1 can only move up and down along the inner wall of the container 4, which can avoid the occurrence of the inclination of the flat plate 4 caused by the first embodiment of the present invention. Deficiencies in the uniform load booster provided.

[0083] In this embodiment, the supporting object 3 ...

Embodiment 3

[0091] See attached Figure 6 And attached Figure 7 , as the first specific implementation of the uniformly distributed load supercharging device provided in Embodiment 2 of the present invention, the uniformly distributed load supercharging device provided in Embodiment 3 of the present invention also includes a connecting pipe 6, and the pressure detection device is a pressure gauge 5 , the connecting pipe 6 is fixedly connected to the outer packaging, the outer packaging communicates with the outside through the connecting pipe 6 , and the pressure gauge 5 is detachably connected to the connecting pipe 6 . See attached Figure 6 A threaded pair is formed between the pressure gauge 5 and the connecting pipe 6, or the pressure gauge 5 is connected to the connecting pipe 6 through a buckle structure. In this embodiment, in order to facilitate the arrangement of the pressure gauge 5 , the plate 1 is provided with a through hole 7 , and the connecting pipe 6 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com