3D display film and stereo display device

A technology of a stereoscopic display device and a display film, applied in the field of 3D display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

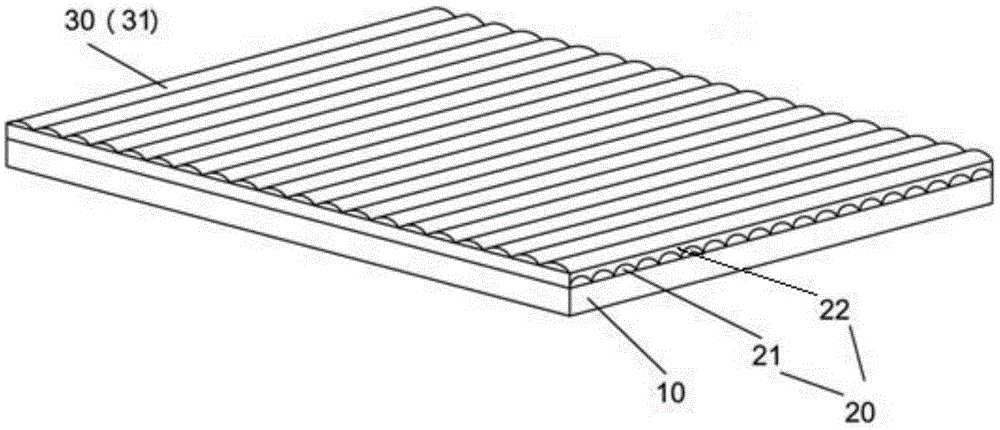

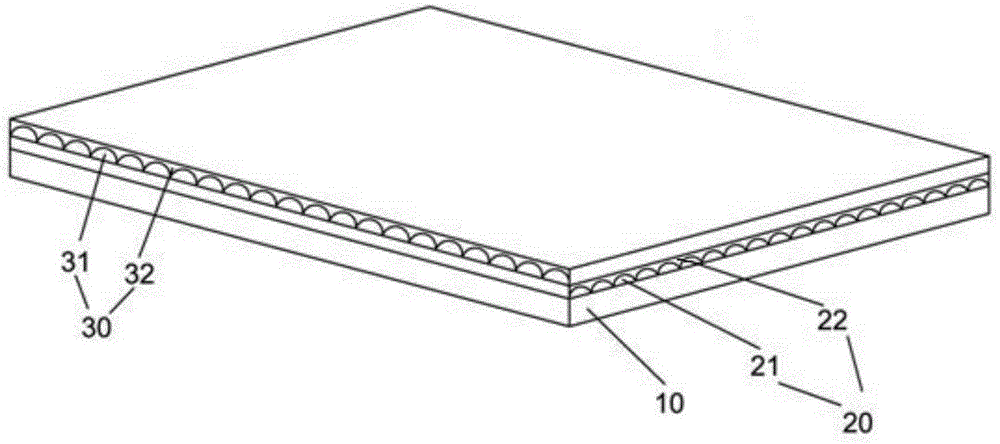

[0059]This embodiment provides a specific three-dimensional display device, which sequentially includes: a 5.98-inch backlight module, an H598DAN01.0 liquid crystal display panel, and a 3D display film from bottom to top. The 3D display film includes from bottom to top: a substrate layer, a first structure layer and a second structure layer.

[0060] Wherein, the substrate layer PET layer has a thickness of 0.125 mm.

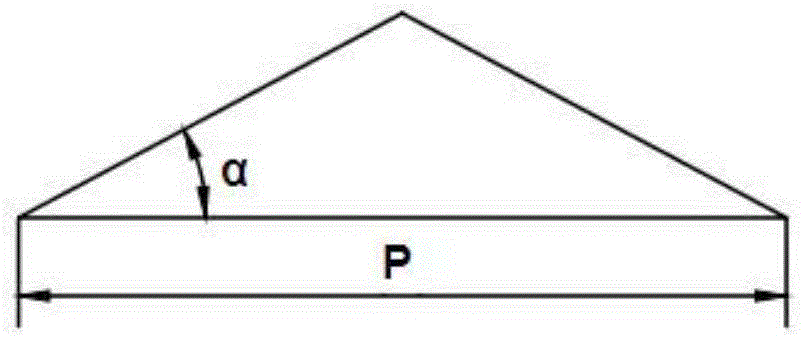

[0061] The first structure layer comprises a first lenticular layer in contact with the substrate layer and a first filling layer positioned on the upper surface of the first lenticular layer, the first lenticular layer is a prism array layer with a refractive index of 1.65; the first filling The upper surface of the layer is flat, and its refractive index is 1.47; the total thickness of the first structure layer is 19 μm.

[0062] The second structure layer includes a second lenticular layer on the upper surface of the first filling layer and a second filling ...

Embodiment 2

[0068] This embodiment provides a specific three-dimensional display device, which sequentially includes: a 19-inch backlight module, an LC190-01-K liquid crystal display panel, and a 3D display film from bottom to top. The 3D display film includes from bottom to top: a substrate layer, a first structure layer and a second structure layer.

[0069] Wherein, the substrate layer PET layer has a thickness of 0.125 mm.

[0070] The first structure layer comprises a first lenticular layer in contact with the substrate layer and a first filling layer positioned on the upper surface of the first lenticular layer, the first lenticular layer is a prism array layer with a refractive index of 1.65; the first filling The upper surface of the layer is flat, and its refractive index is 1.47; the total thickness of the first structure layer is 26 μm.

[0071] The second structure layer only includes the second lenticular lens layer on the upper surface of the first filling layer, and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com