3D display film and stereoscopic display device

A technology of a stereoscopic display device and a display film, applied in the field of 3D display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

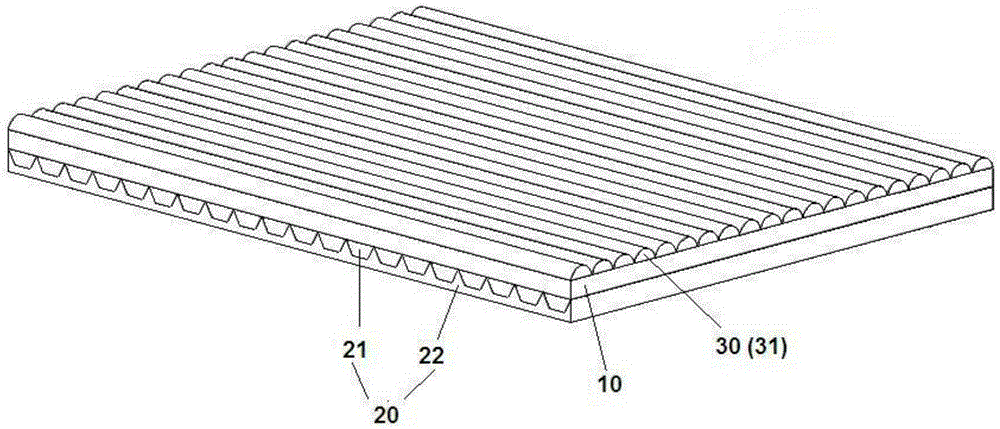

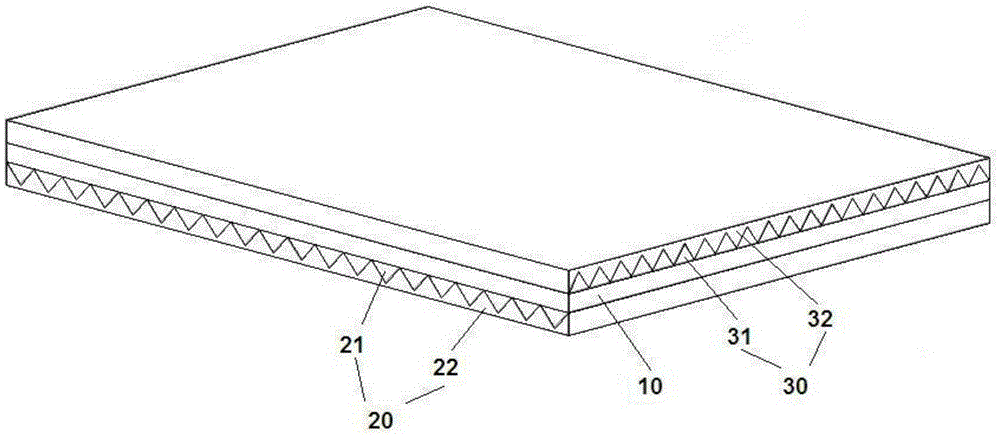

[0060] This embodiment provides a specific three-dimensional display device, which sequentially includes: a 5.98-inch backlight module, an H598DAN01.0 liquid crystal display panel, and a 3D display film from bottom to top. Wherein the 3D display film comprises: a substrate layer, a first structural layer positioned on the lower surface of the substrate layer (the substrate layer is close to the surface of the liquid crystal display panel), and positioned on the substrate layer upper surface (the substrate layer is away from the surface of the liquid crystal display panel) ) of the second structural layer.

[0061] Wherein, the substrate layer PET layer has a thickness of 0.125 mm.

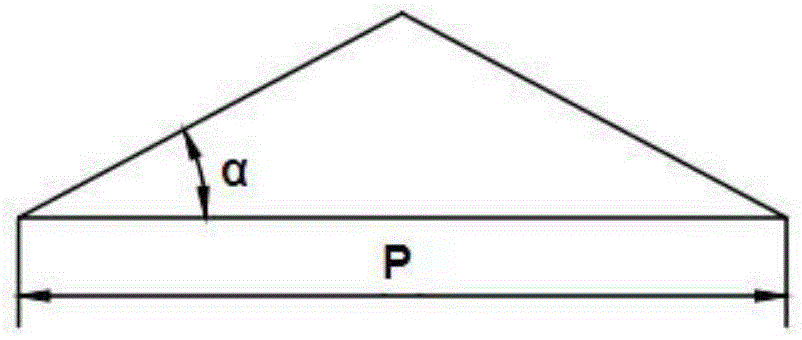

[0062] The first structure layer comprises a first lenticular lens layer in contact with the substrate layer and a first filling layer positioned on the surface of the first lenticular lens layer away from the substrate layer, the first lenticular lens layer is a prism array layer, and the bottom s...

Embodiment 2

[0069] This embodiment provides a specific three-dimensional display device, which includes from bottom to top: a 5.5-inch backlight module, a TL055VYXP01 liquid crystal display panel, and a 3D display film. Wherein the 3D display film comprises: a substrate layer, a first structural layer positioned on the lower surface of the substrate layer (the surface of the substrate layer close to the liquid crystal display panel) and an upper surface of the substrate layer (the surface of the substrate layer away from the liquid crystal display panel) the second structural layer.

[0070] Wherein, the substrate layer PET layer has a thickness of 0.125 mm.

[0071] The first structure layer comprises a first lenticular lens layer in contact with the substrate layer and a first filling layer positioned on the surface of the first lenticular lens layer away from the substrate layer, the first lenticular lens layer is a prism array layer, and the bottom surface of the prism is in contact w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com