Capacitive touch screen with fingerprint recognition function and manufacturing method

A technology of capacitive touch screen and fingerprint recognition, which is applied in character and pattern recognition, electrical digital data processing, input/output process of data processing, etc. It can solve the problems of inability to install fingerprint recognition modules, damage to the strength of glass cover boards, and rising production costs and other issues to achieve the effect of saving production costs, submitting production efficiency, and ensuring the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

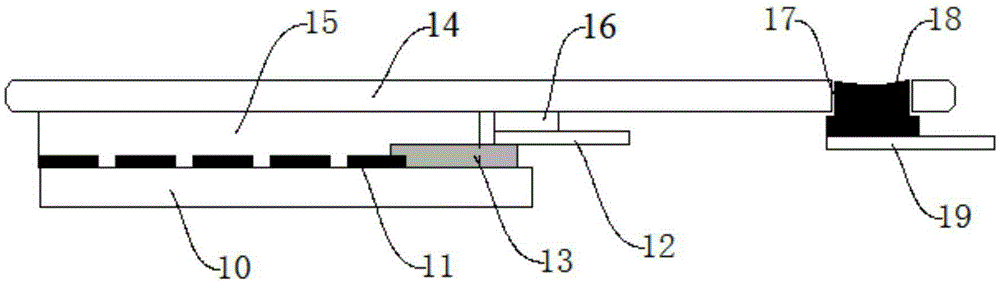

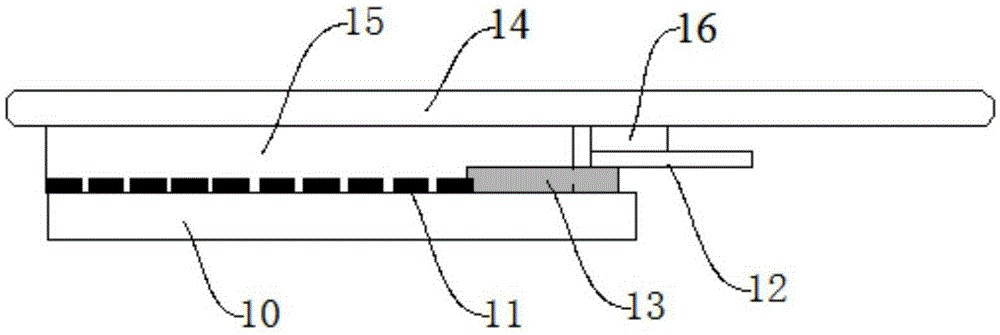

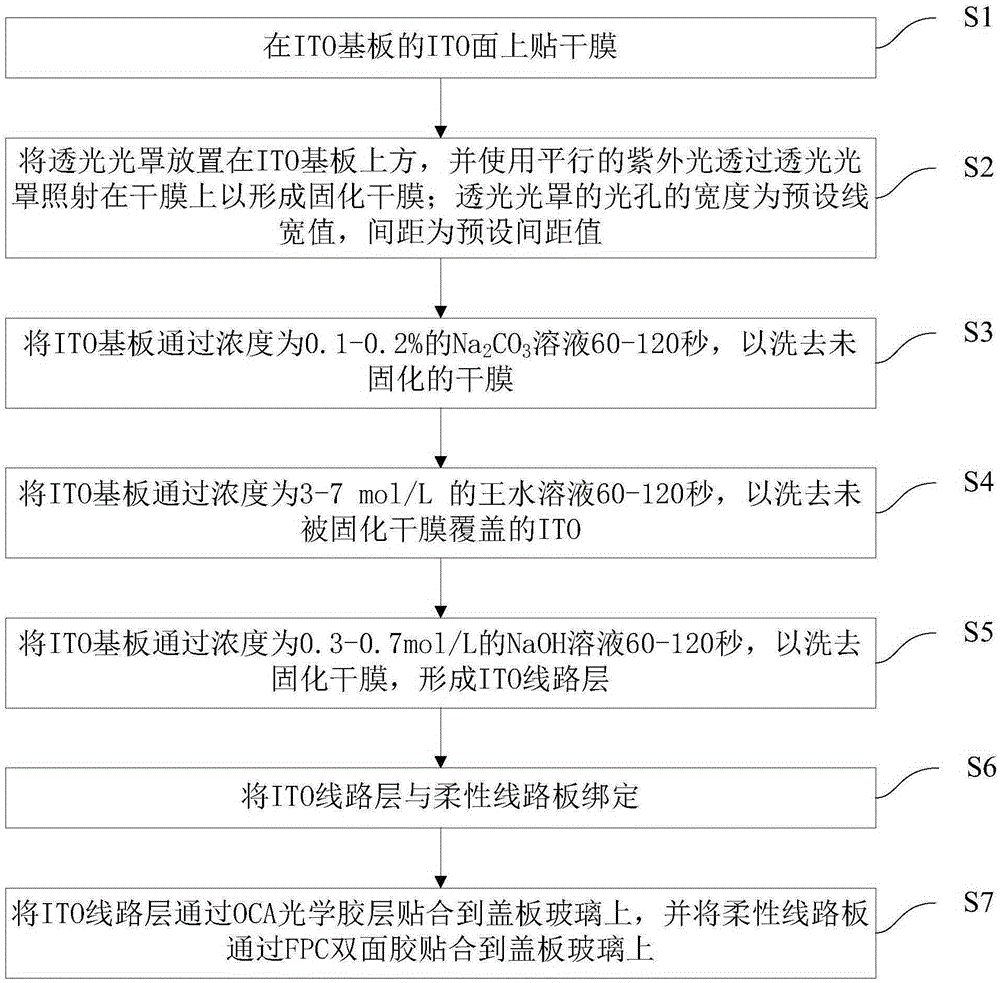

[0030] figure 2 The capacitive touch screen with fingerprint recognition function shown in this embodiment is shown. The capacitive touch screen with fingerprint identification function includes an ITO substrate 10 , an ITO circuit layer 11 disposed on the ITO substrate 10 and a flexible circuit board 12 connected to the ITO circuit layer 11 . Among them, the ITO substrate 10 is a layer of PET film that has been hardened and coated on it. It has good electrical insulation, and its electrical properties are still good under high temperature and high frequency conditions, and the ITO substrate 10 has good creep resistance. Denaturation, fatigue resistance and friction resistance are all very good. The ITO line layer 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com