Automatic energy-saving gluing device for horn production

A gluing device and gluing technology, applied in the direction of sensors, electrical components, etc., can solve the problems of excessive gluing and difficulty in achieving effective gluing, and achieve the effects of ensuring product quality, reducing material costs, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

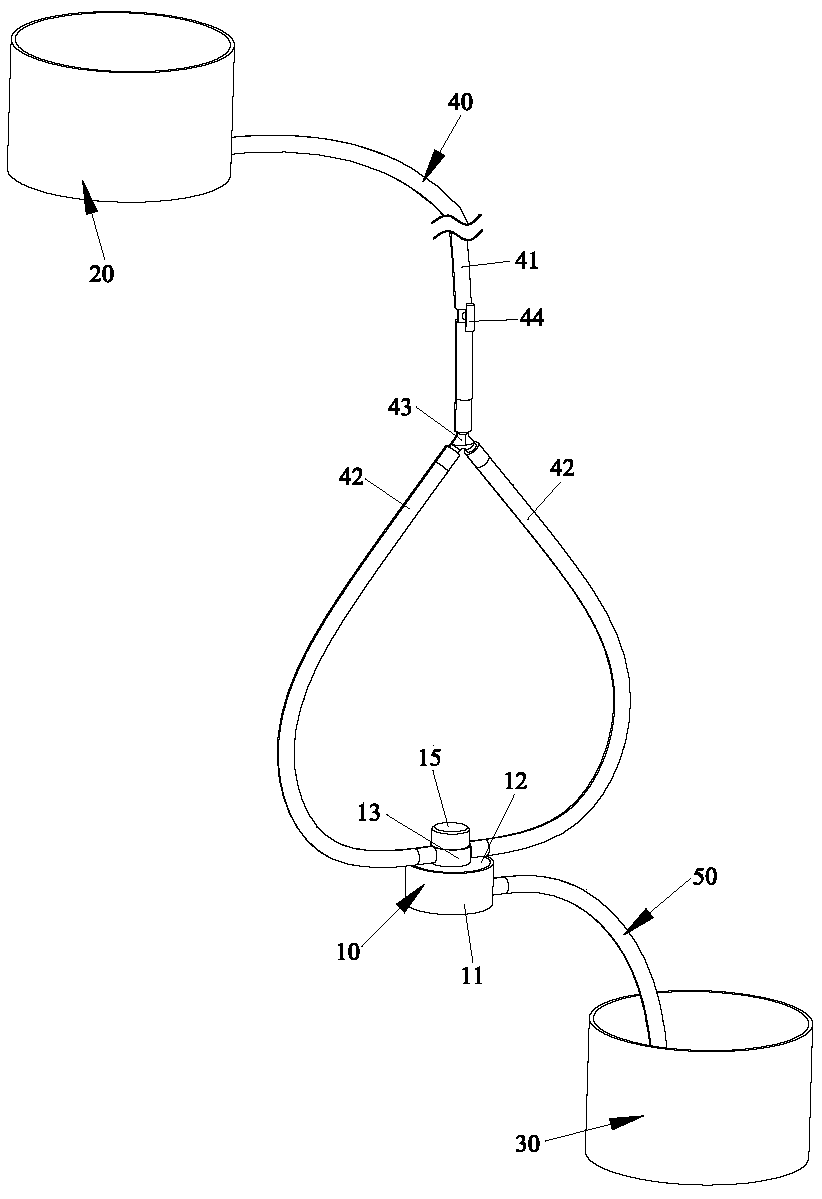

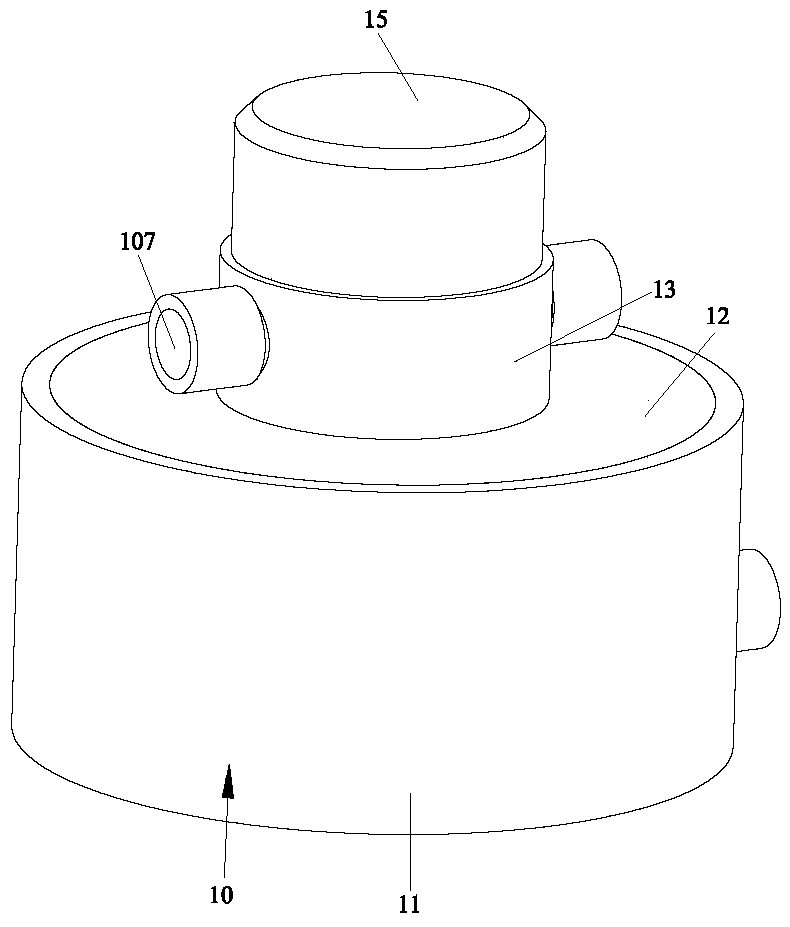

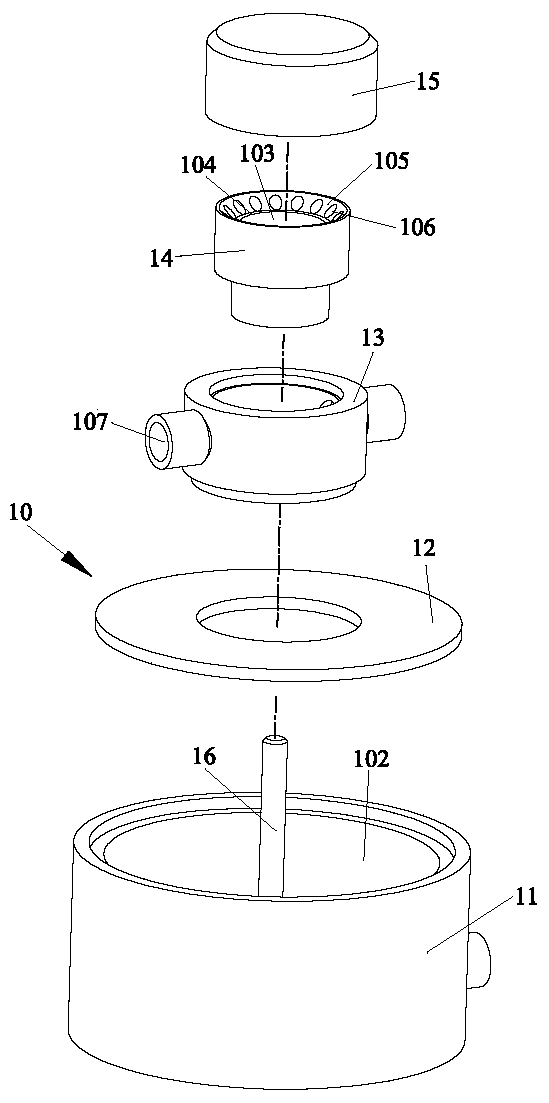

[0033] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a glue application container 10 , a glue storage container 20 and a glue return container 30 .

[0034] The gluing container 10 has a ring-shaped gluing groove 101 and a glue returning chamber 102. The top of the gluing container 10 has a gluing hole 103, a gluing stepped surface 104 and a gluing inclined surface 105. The gluing hole 103 communicates with the gluing chamber. 102, the gluing stepped surface 104 is located at the periphery of the glue return hole 103, the gluing inclined surface 105 is located at the periphery of the gluing stepped surface 104, and the gluing inclined surface 105 is provided with a plurality of gluing holes 106, and the gluing inclined surface 105 is provided with a plurality of gluing holes 106. The holes 106 are evenly distributed on the periphery of the glue returning hole 103, and each glue outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com