Manufacturing technology and equipment for ultrathin amorphous alloy mobile telephone shell

An amorphous alloy, mobile phone shell technology, applied in the field of ultra-thin amorphous alloy mobile phone shell manufacturing technology and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

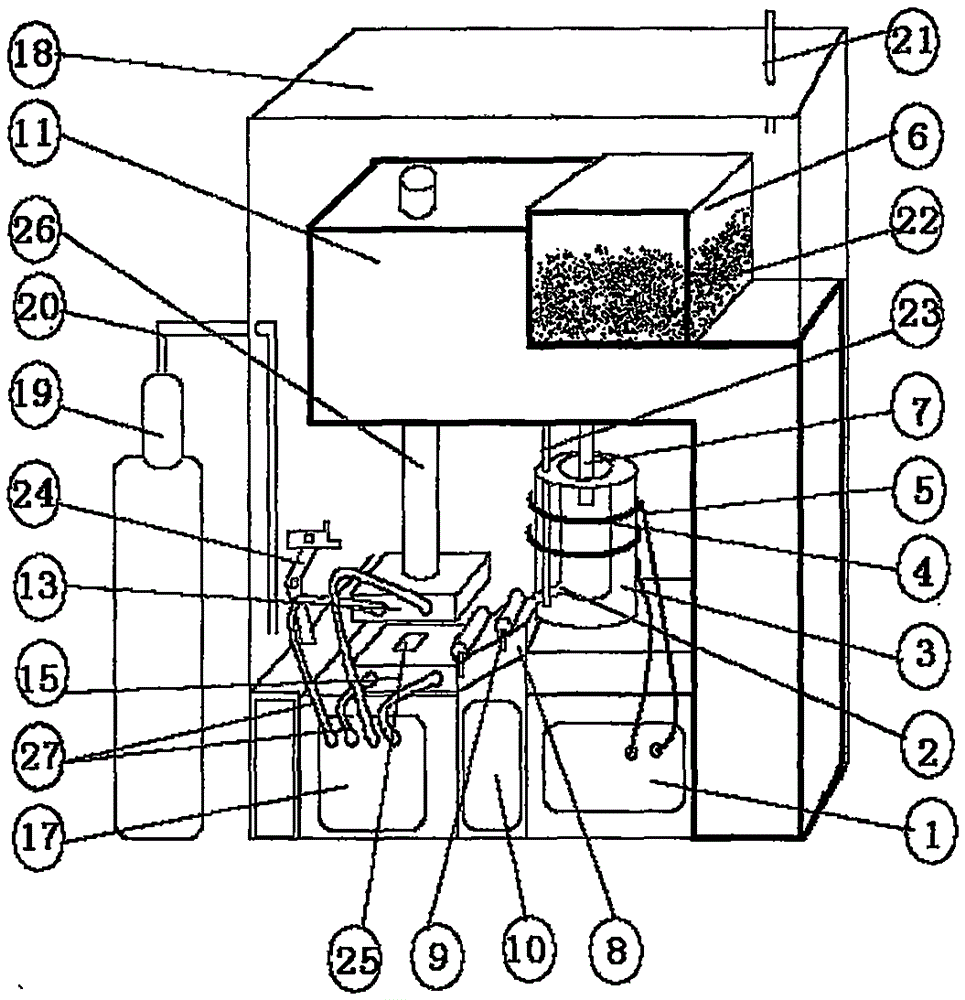

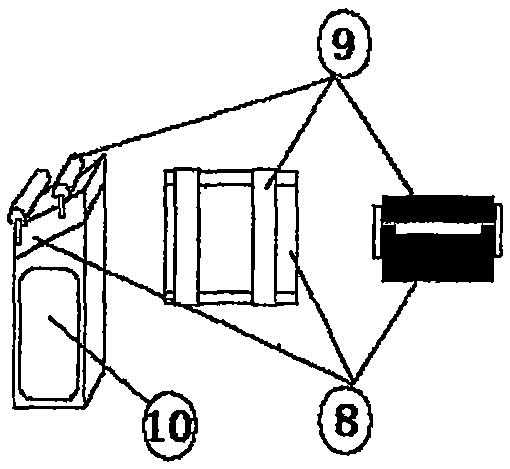

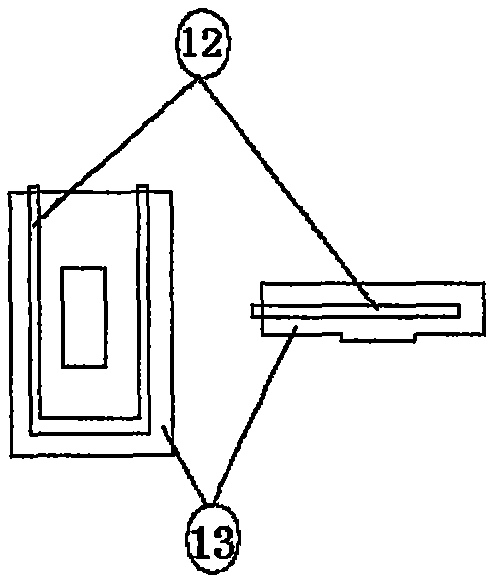

[0019] The optimal design scheme of amorphous alloy mobile phone casing manufacturing equipment is:

[0020] Ultra-thin amorphous alloy metal mobile phone shell manufacturing technology and equipment are composed of raw material melting system, hot rolling system, stamping system and non-vacuum system. The raw material melting system solves the problem of rapid liquefaction of amorphous alloys, the hot rolling system solves the plate-shaped material suitable for stamping, the stamping system solves the problem of rapid solidification of mobile phone casings, and the non-vacuum system solves the problem of isolating air during melting and stamping.

[0021] The raw material melting system adopts high-frequency coil (4) electromagnetic heating to solve the problem of rapidly melting amorphous alloy raw materials, and the ceramic melting furnace (3) is not affected by high-frequency electromagnetic and can withstand high temperature. When the high-frequency coil (2) is heated, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com