Material pumping device

A pumping tube and hopper technology, applied in the field of pumping devices, can solve the problems of insufficient insertion depth, mixing of liquid components, and inability to guarantee accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Aiming at the problem of layered extraction of layered liquid materials (such as coatings, glues, paints, etc.), the present invention provides a material extraction device, which is used to extract liquids from containers with upper openings, especially liquids that require layers .

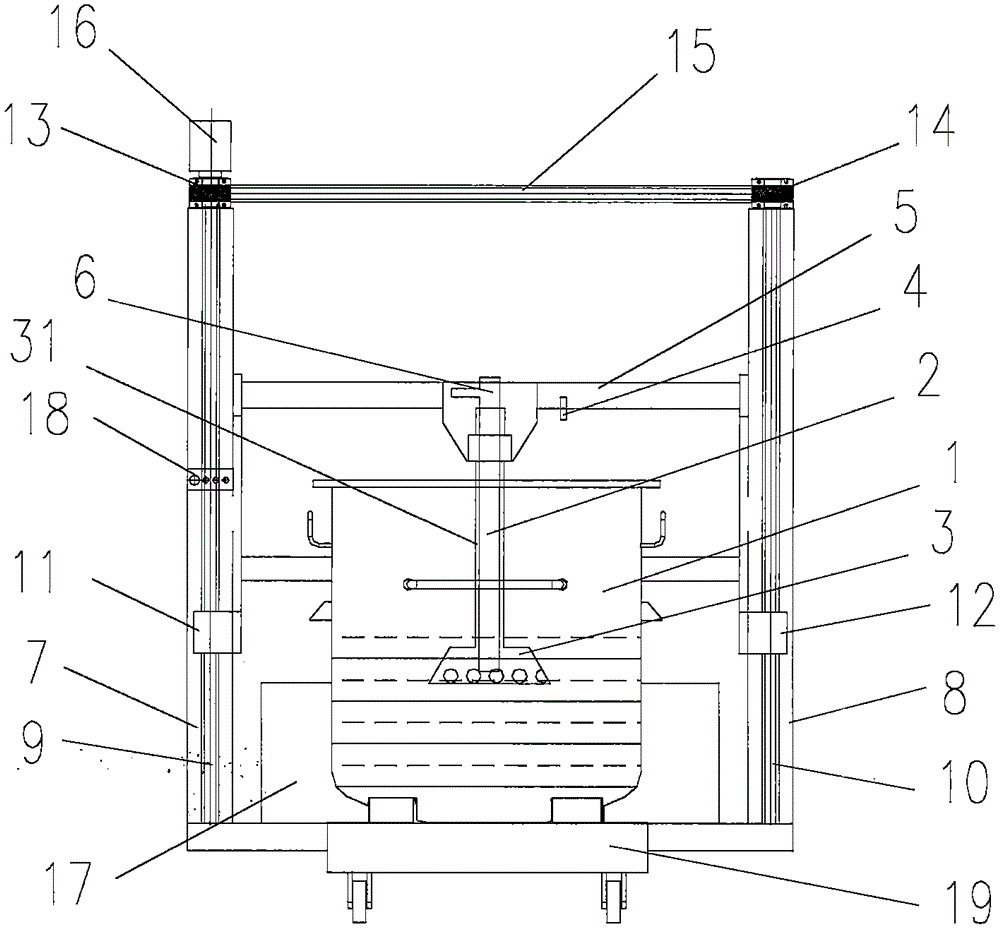

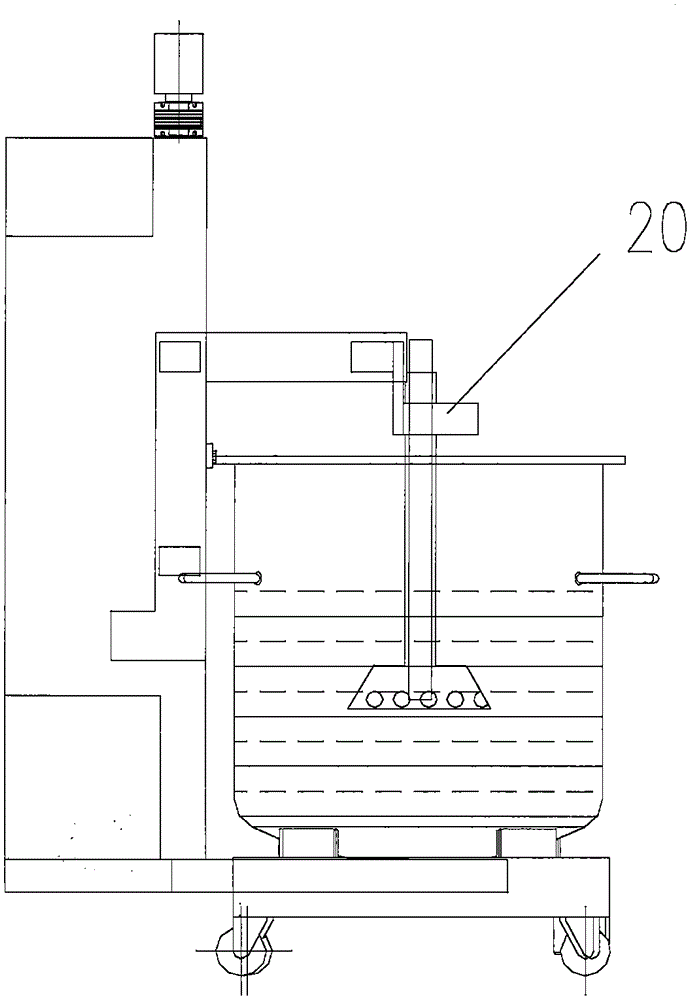

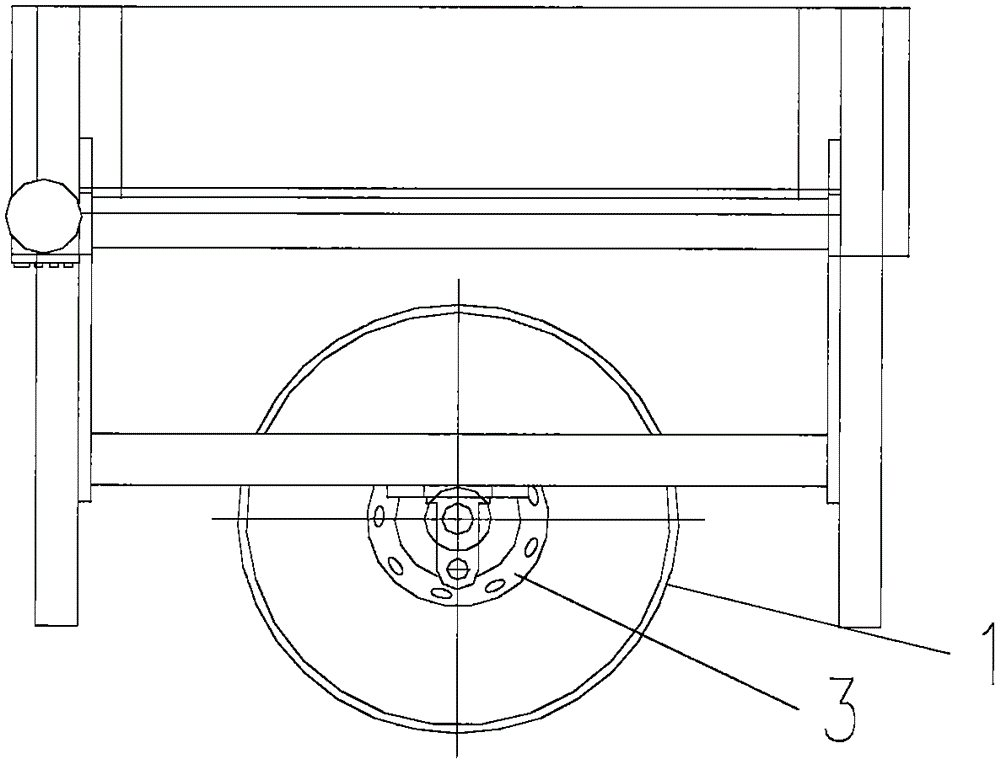

[0025] first see attached Figure 1-3 , the liquid material to be extracted is placed in a container 1 (such as a material cylinder, material barrel, material storage box, etc.) with an upper opening. The material pumping device of the present invention mainly includes a material pumping mechanism and a driving mechanism. Wherein, the material pumping mechanism comprises a material extraction pipe 2 and an isolation cover 3, the inlet of the material extraction tube 2 (usually at its end) is located in the isolation cover 3, and the side of the isolation cover 3 is provided with Pumping openings (such as one or more round holes or slotted holes on the side). Wherein, the pumping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com