Air valve capable of monitoring work state

A working state, air valve technology, applied in valve devices, engine components, mechanical equipment, etc., can solve problems such as hidden safety hazards, air valves can not be found in time, air valves cannot meet requirements, etc., to improve safety, simple and effective structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

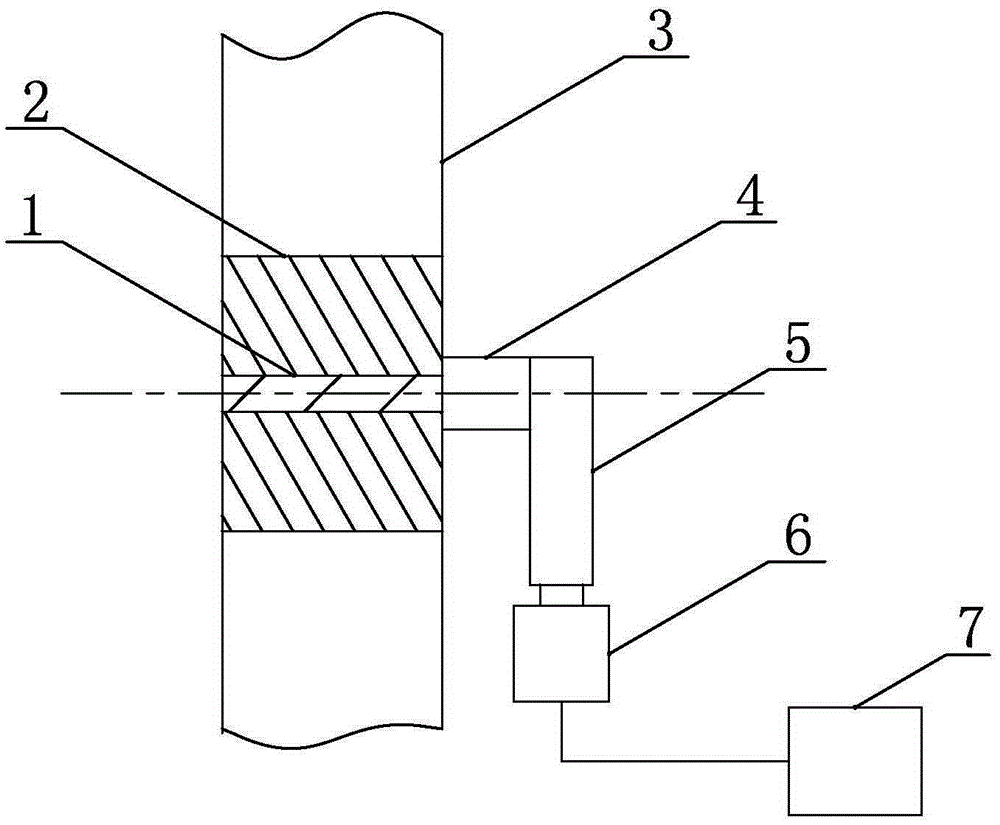

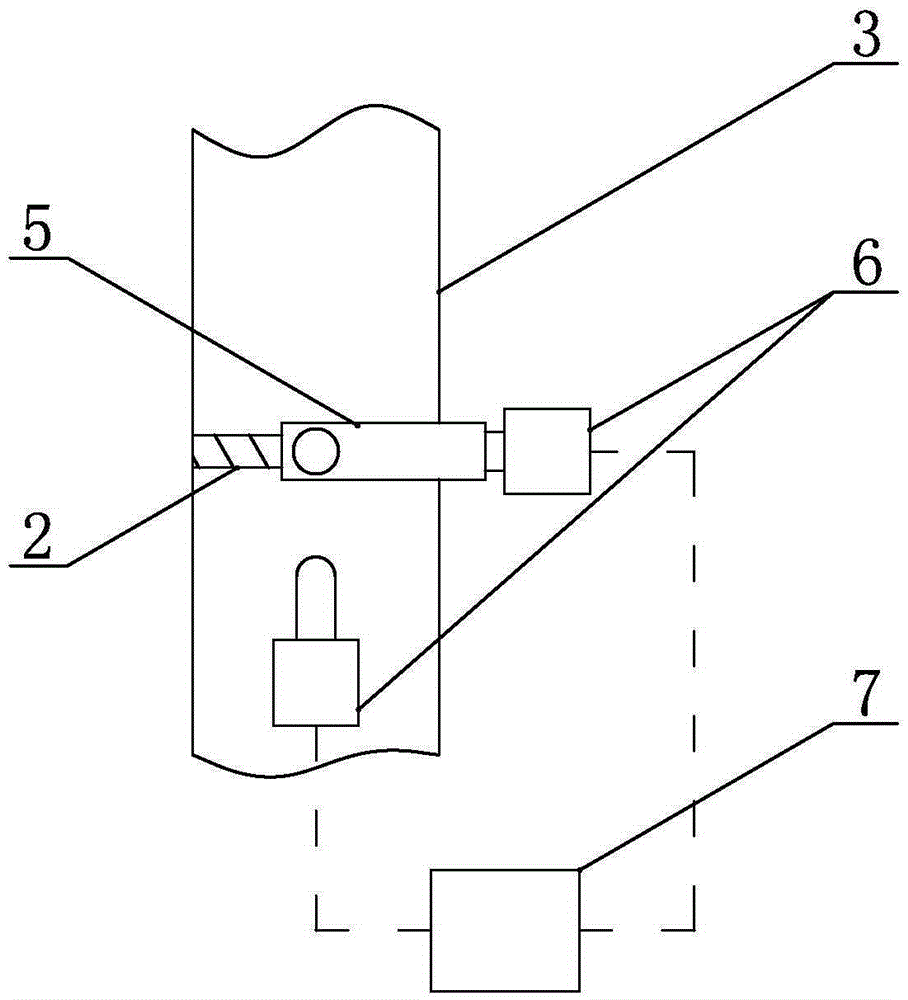

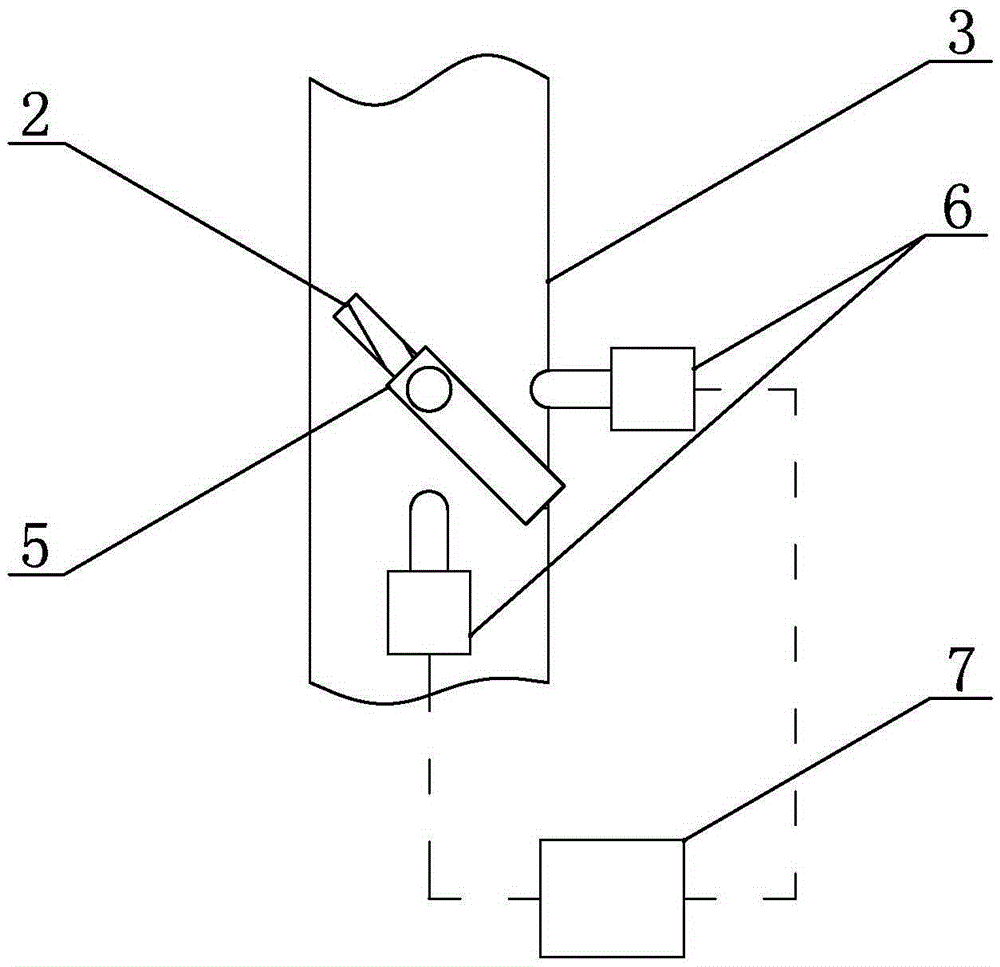

[0015] Such as figure 1 As shown, the air valve capable of monitoring the working state of the present invention includes a valve shaft 1 and a valve disc 2, the valve shaft 1 drives the valve disc 2 to rotate, the left and right ends of the valve shaft 1 are installed on the air duct 3, and are perpendicular to the air duct 3 installed in the air inlet direction. A protruding part 4 is processed on the end surface of the valve shaft 1 along the length direction of the valve shaft 1, and a sensing terminal 5 is connected to the protruding part 4, and the sensing terminal 5 is located outside the air duct. The sensing terminal 5 can rotate along the same rotation axis as the valve shaft 1 . Two vertically placed inductors 6 are arranged in the plane formed by the rotation of the sensing terminal 5 . Such as Figure 5 As shown, the sensor 6 includes a casing 9, and an inductive element 8 is arranged inside the casing 9. The inductive element 8 is a signal sensor capable of ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com