Gravity flow liquid sampler

A sampler and gravity flow technology, applied in the field of gravity flow liquid samplers, can solve the problems of cumbersome devices, inability to measure fluids, complicated operations, etc., and achieve the effects of improving safety, reducing manpower, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

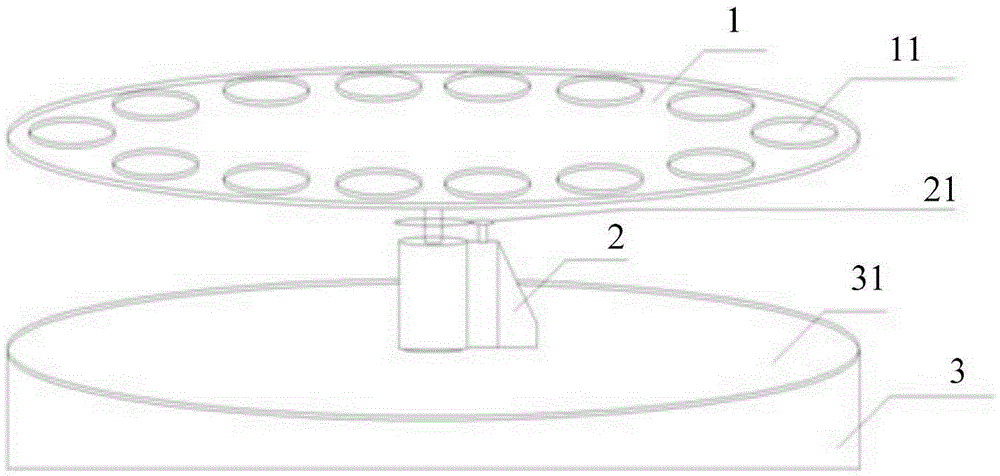

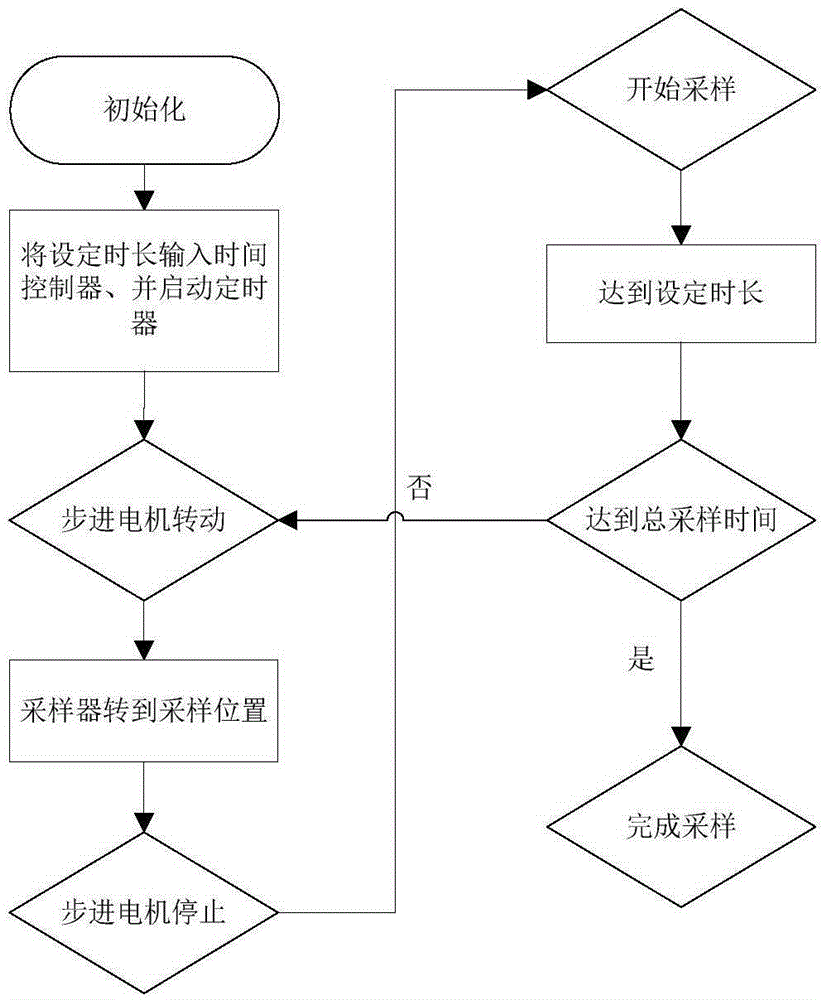

[0038] combine figure 1 and figure 2 As shown, a gravity flow liquid sampler provided by an embodiment of the present invention includes a turntable 1, a liquid outlet pipe, a solenoid valve, a power unit 2, a timing controller, and a plurality of sampling bottles.

[0039] Wherein, the power device 2 is used to drive the turntable 1 to rotate. The power device 2 specifically includes a bearing base and a rotating shaft, and the bearing base is fixedly arranged; center position to drive the turntable 1 to rotate. The stepping motor is fixedly connected with the bearing base, so that the output shaft of the stepping motor is arranged side by side with the rotating shaft, and the first gear and the second gear 21 are respectively arranged on the rotating shaft and the output shaft of the stepping motor, and the first gear It meshes with the second gear 21, so that the output shaft of the stepping motor and the rotating shaft form a gear transmission connection.

[0040] The ...

Embodiment 2

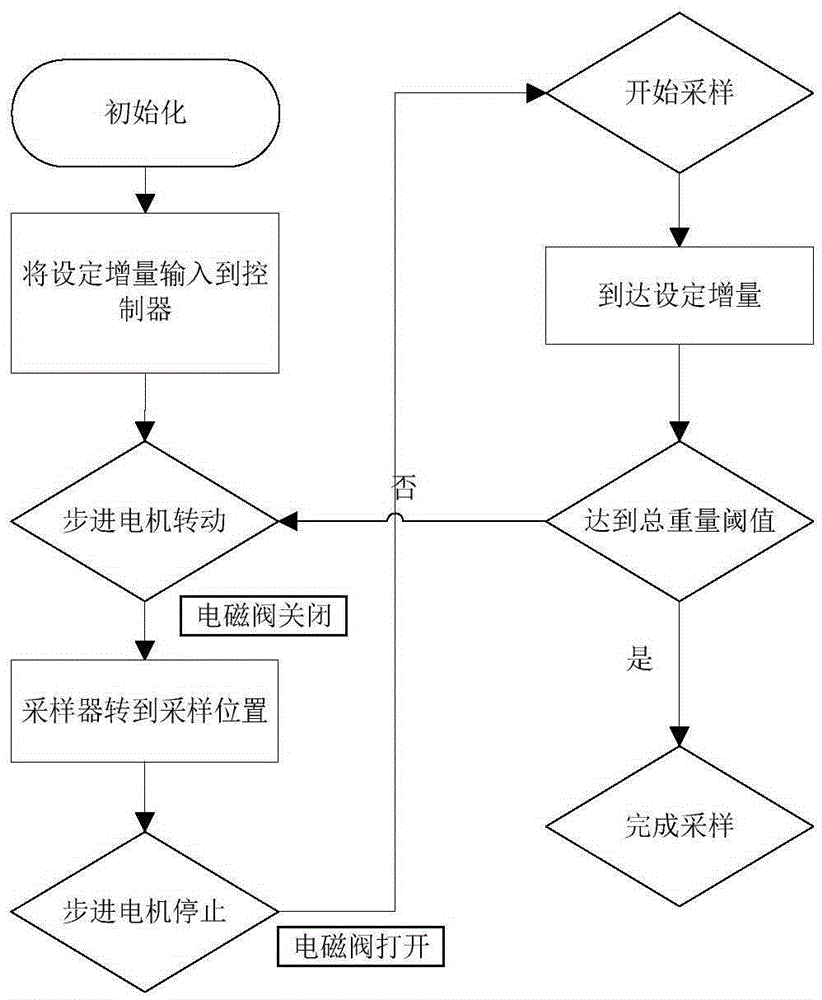

[0047]A gravity flow liquid sampler provided in Embodiment 2 of the present invention is basically the same in structure as Embodiment 1, and the similarities will not be described again. The difference lies in:

[0048] combine figure 1 and image 3 As shown, the timing controller in the first embodiment is replaced by the weighing module 3 and the controller.

[0049] Specifically, both the bearing base and the stepper motor are fixed on the weighing pan 31 of the weighing module 3, so that the weighing device can weigh the overall weight of the power unit 2, the turntable 1 and a plurality of sampling bottles.

[0050] The weighing module 3 is connected with the controller, and feeds back the overall weight information of the above-mentioned power device 2, the turntable 1 and a plurality of sampling bottles to the controller in real time, and the controller takes the set increment as the control condition. When the above-mentioned overall weight increment When the set in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com