Automatic weighing system and method for solid particle or powder materials

An automatic weighing and solid particle technology, which is applied in the direction of weighing equipment, weighing, and measuring devices for materials with special properties/forms, and can solve problems such as low efficiency of sample splitting, inapplicability of sample splitters, and sample loss , to achieve the effect of realizing automatic operation, improving weighing efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

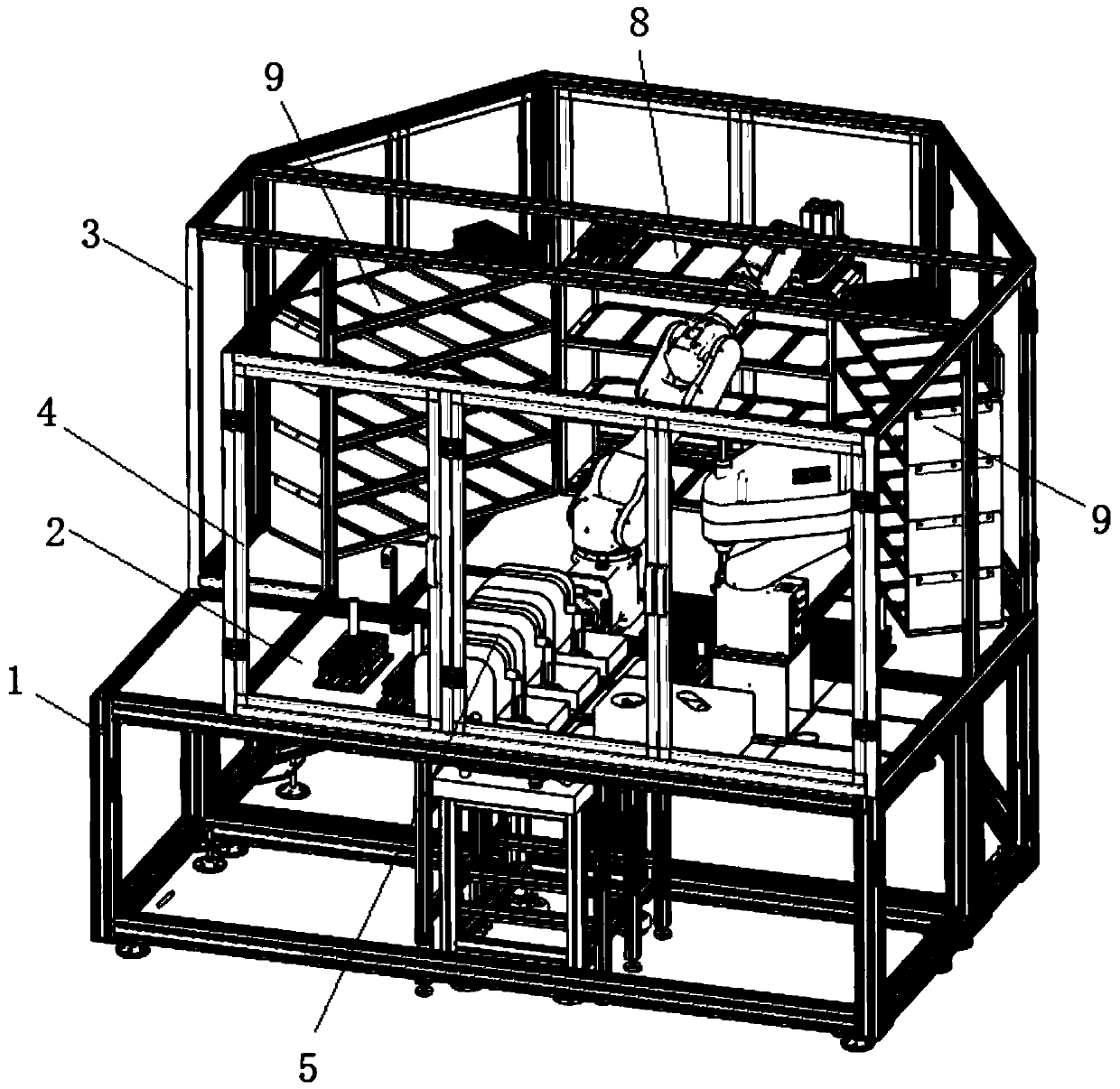

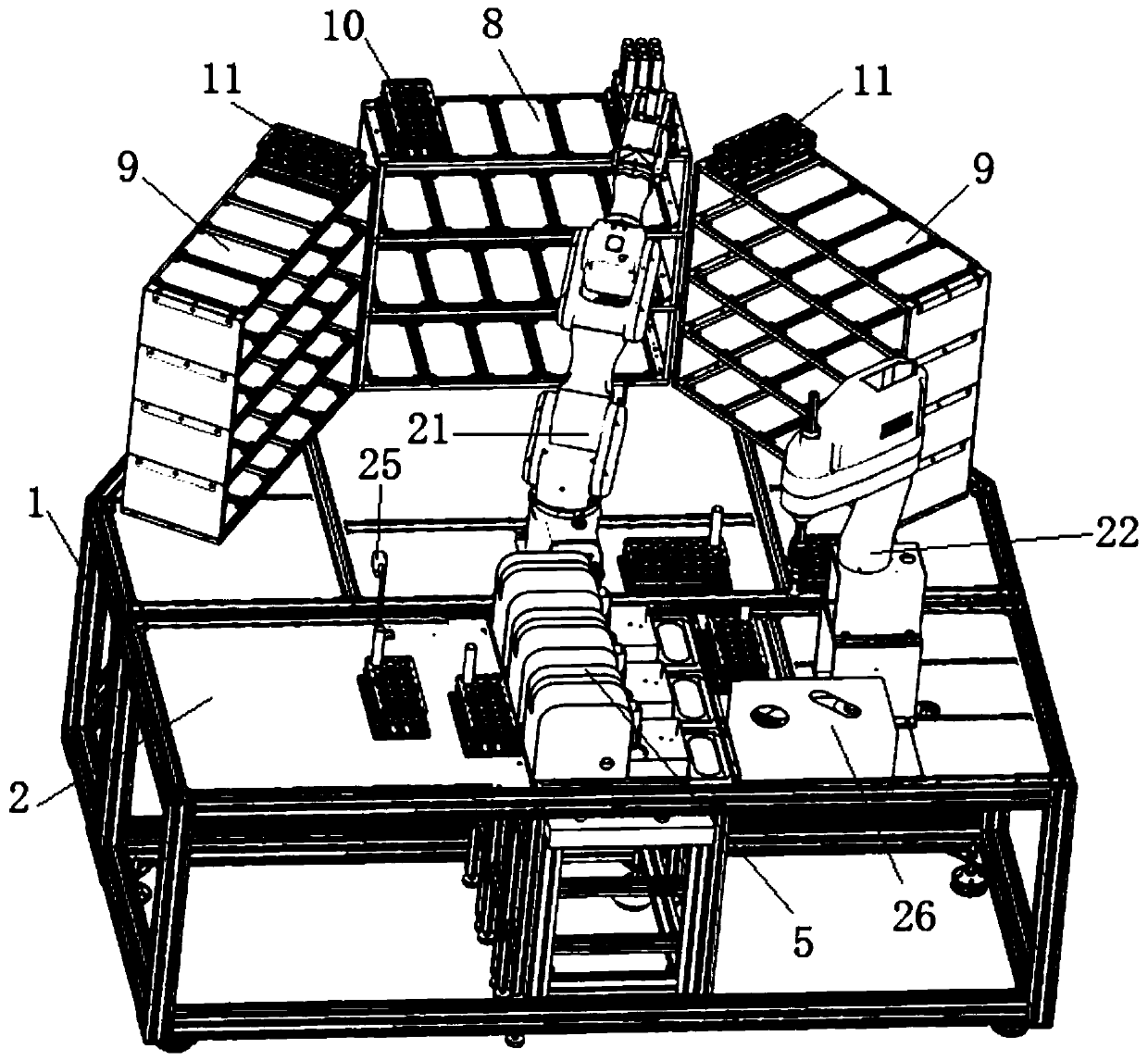

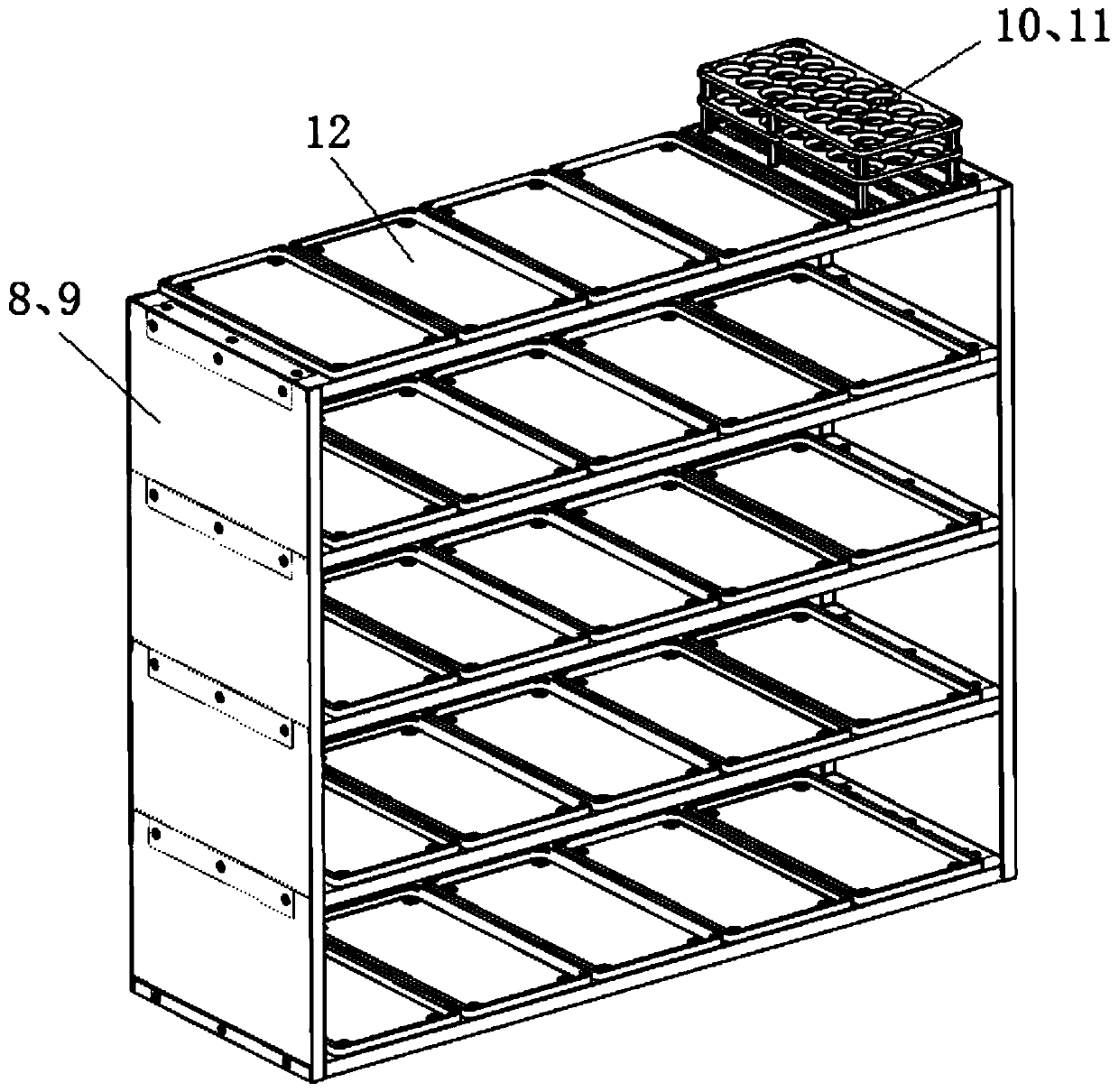

[0038] See attached figure 1 , attached figure 2 , attached Figure 5 and attached Figure 6 , the automatic weighing system of the present invention is installed on the workbench 2 of the frame 1, a frame 3 is arranged on the workbench 2, and the frame 3 is a transparent glass frame structure, and the automatic weighing system is relatively sealed and arranged in the frame 3, transparent The frame structure facilitates observation during work, and the frame 3 is provided with an operation door 4 for input and output of samples and other components. A weighing device 5, a source sample container 6, a target sample container 7 and a robot are set on the workbench 2, and the background controller controls the robot to send the source sample container 6 and the target sample container 7 to the sample input port 13 of the sample weighing device 5 and the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com