Continuous vacuum casting device and method for silver alloy

An ingot casting equipment and silver alloy technology, applied in the field of metal casting, can solve problems such as inability to realize continuous operation and limit industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

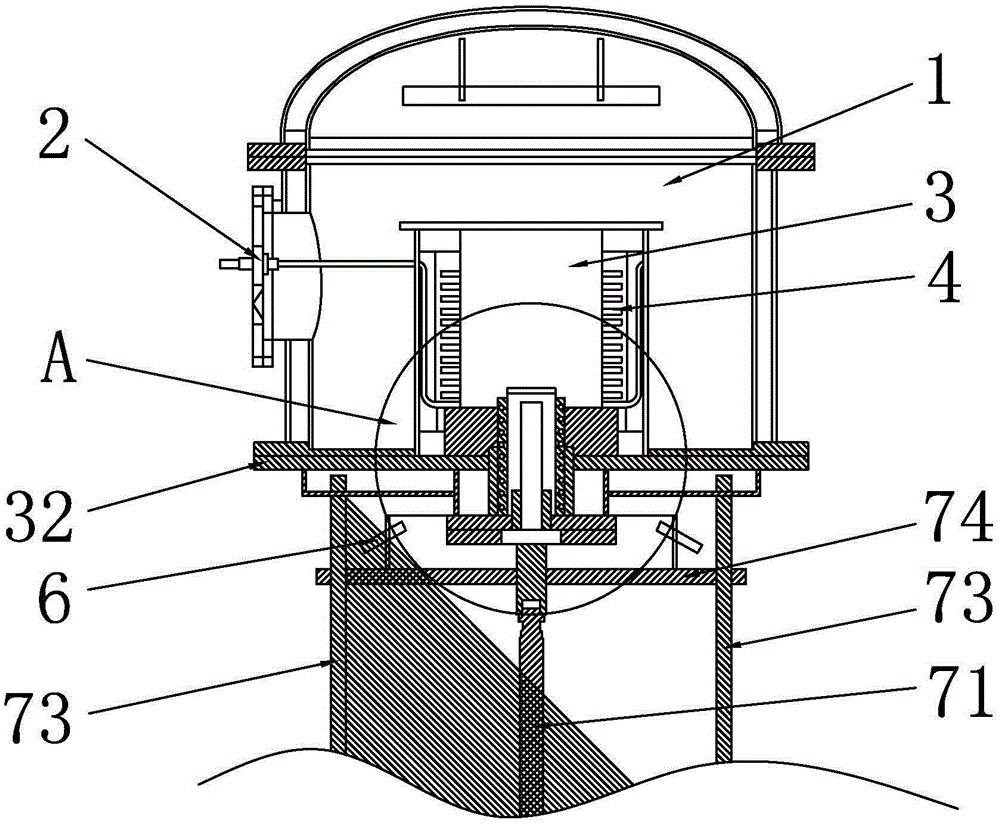

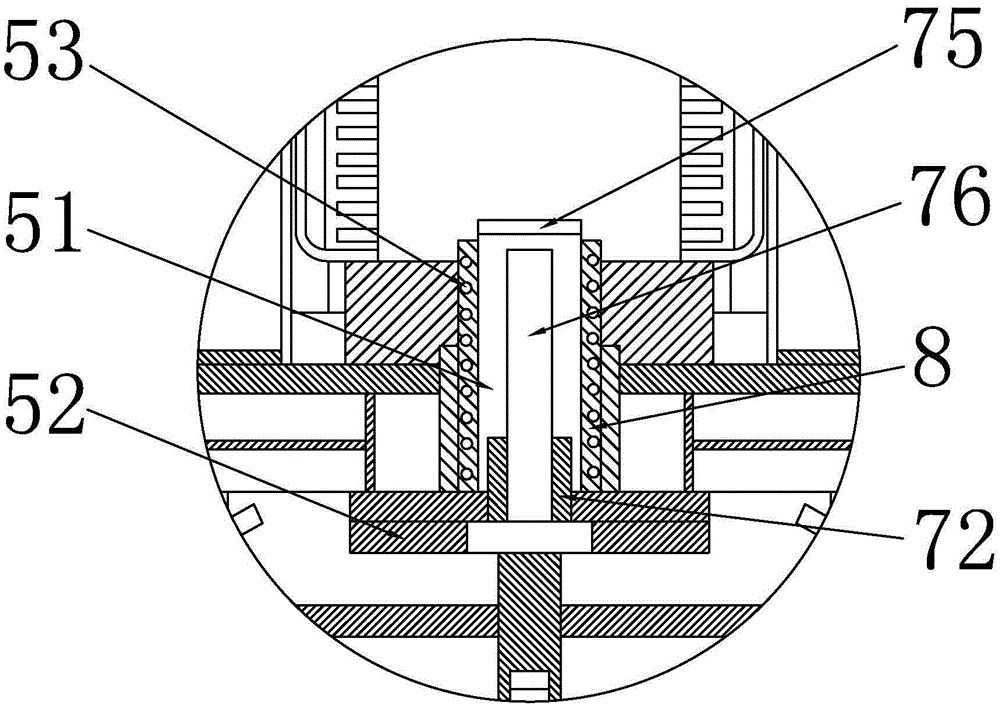

[0038] The continuous vacuum ingot casting equipment of a kind of silver alloy of present embodiment is as figure 1 and figure 2 As shown, it includes a vacuum chamber 1 and a crystallizer 5. The vacuum chamber 1 is provided with a graphite crucible 3, the wall of the graphite crucible 3 is provided with a heating device, and the bottom of the graphite crucible 3 is provided with a liquid silver outlet. The silver liquid outlet is connected with the crystallizer 5, and the periphery of the crystallizer 5 is provided with a cooling device 8, and the liquid silver liquid outlet is provided with a traction device for drawing liquid silver to the crystallizer and pulling out the solid silver formed in the crystallizer , the pulling device is located in the crystallizer 5, and can move up and down in the crystallizer 5.

[0039] The device has a simple structure and is easy to operate.

[0040] The working principle of this embodiment is:

[0041] Put four silver plates with a...

Embodiment 2

[0062] The continuous vacuum ingot casting method of a kind of silver alloy of the present embodiment is to utilize the continuous vacuum casting equipment of a kind of silver alloy of embodiment 1, and concrete operation steps are as follows:

[0063] The sealing flange 52 is locked to seal the crystallizer 5,

[0064] The drawing die 75 is arranged on the liquid silver liquid outlet of the graphite crucible 3, and the liquid silver liquid outlet is sealed at the same time, so that the silver ingot is heated by the heating device in the vacuum chamber 1 to fully melt into liquid silver,

[0065] Then loosen the sealing flange 52,

[0066] The hydraulic system drives the traction mold 75 to move down to the crystallizer 5 through the connector 72 and the traction rod 71. The traction speed of the hydraulic system is 80mm / min. The hydraulic system is outwardly drawn by 5mm and then retracted by 2mm. Repeat this continuously.

[0067] Once the liquid silver in the drawing die 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap