Turning tools for universal joints

A technology of turning tools and universal joints, which is applied in the direction of thread cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the threads are not on the same concentric circle, cannot meet the large-scale production of manufacturers, and cannot use the same tool, etc. Achieve the effects of easy processing, saving purchase cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

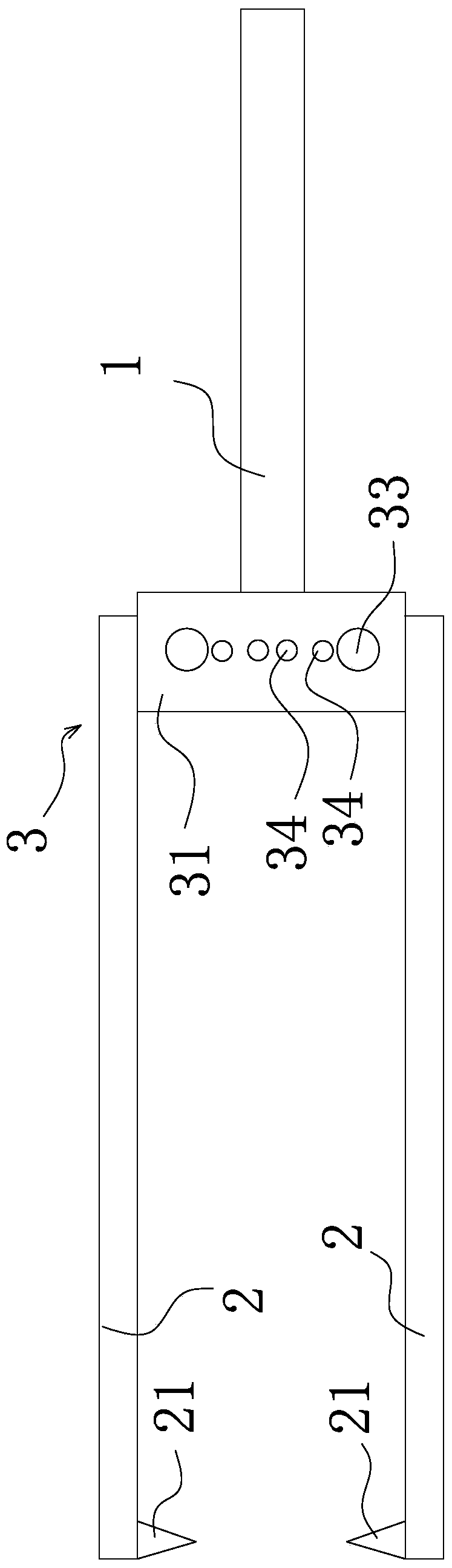

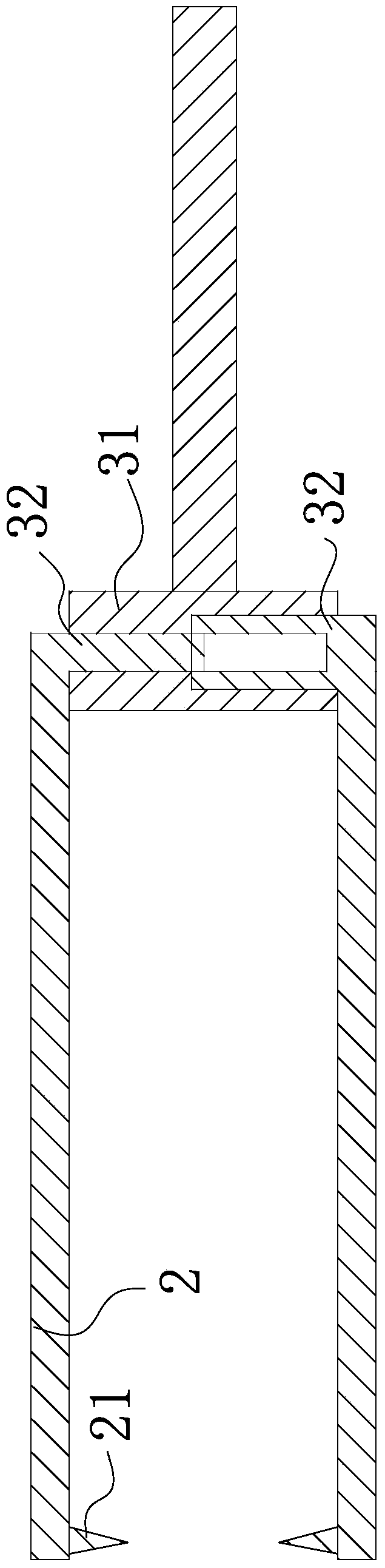

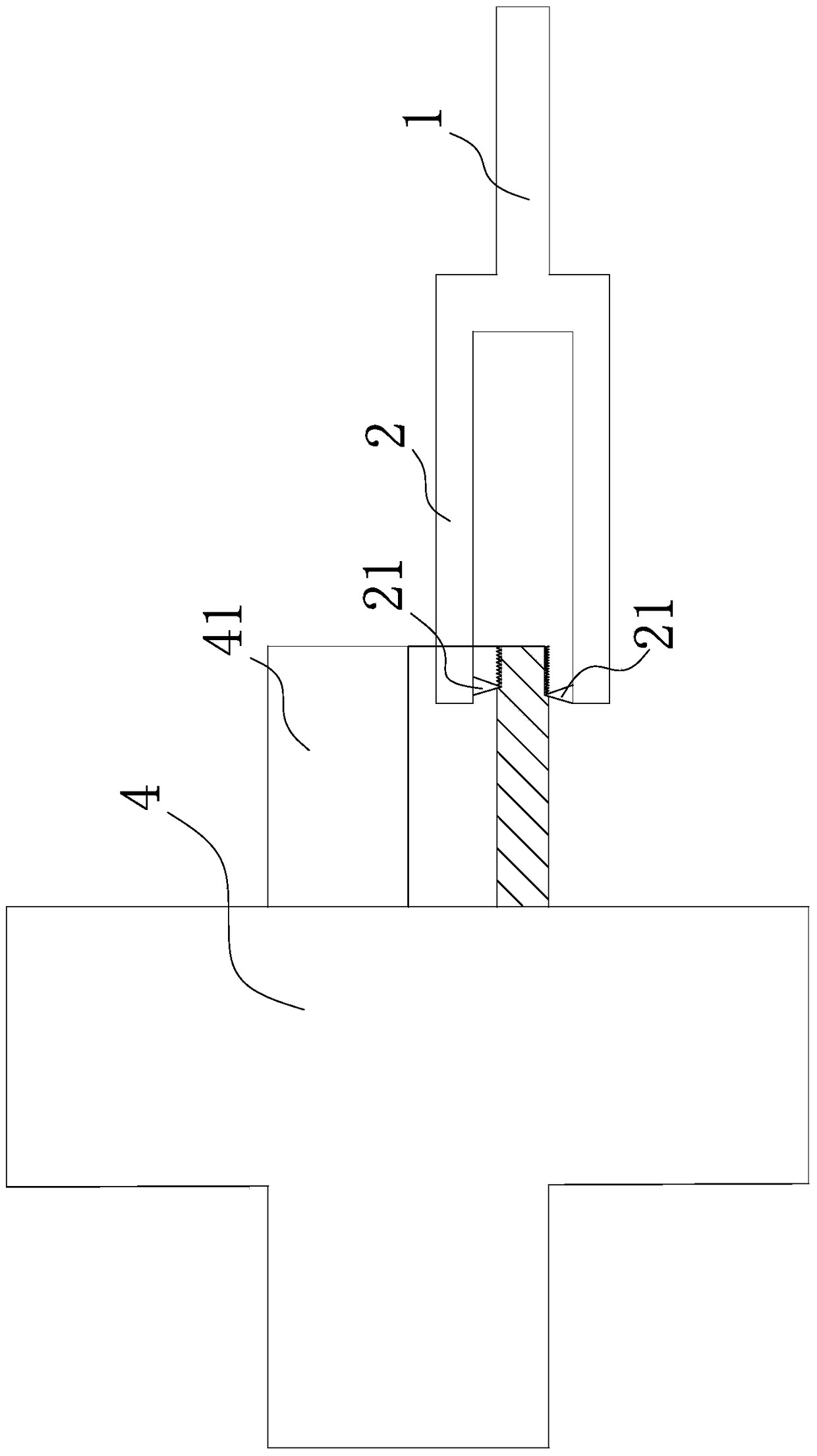

[0020] Such as Figure 1-3 As shown, the turning tool of this universal joint includes a columnar tool handle 1, one end of the tool handle 1 is provided with two opposing tool bars 2, and the outer end of each tool bar 2 is provided with a tool head 21 arranged inwardly. , Between the knife rods 2 and the knife handle 1, there is a distance adjustment assembly 3 capable of adjusting the distance between the two knife rods 2, and the knife rod 2 is connected to the knife handle 1 through the distance adjustment assembly 3.

[0021] More specifically, the spacing adjustment assembly 3 includes a positioning tube 31 arranged at one end of the knife handle 1, the positioning tube 31 is perpendicular to the knife handle 1, and the two ends of the positioning tube 31 are pierced with telescopic rods 32, and each telescopic rod 32 passes through the positioning tube. The screw 33 is fixed, and the tube wall at both ends of the positioning tube 31 is symmetrically provided with a num...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap