Lathe fixture of polygonal parts

A lathe fixture and polygon technology, which is used in metal processing mechanical parts, clamping, clamping devices, etc., can solve the problems of low repeated positioning accuracy, difficulty in ensuring the shape and position tolerance of parts, and difficulty in alignment, and achieve positioning accuracy. And the repeat positioning accuracy is not high, the work efficiency is improved, and the labor intensity is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described in further detail below:

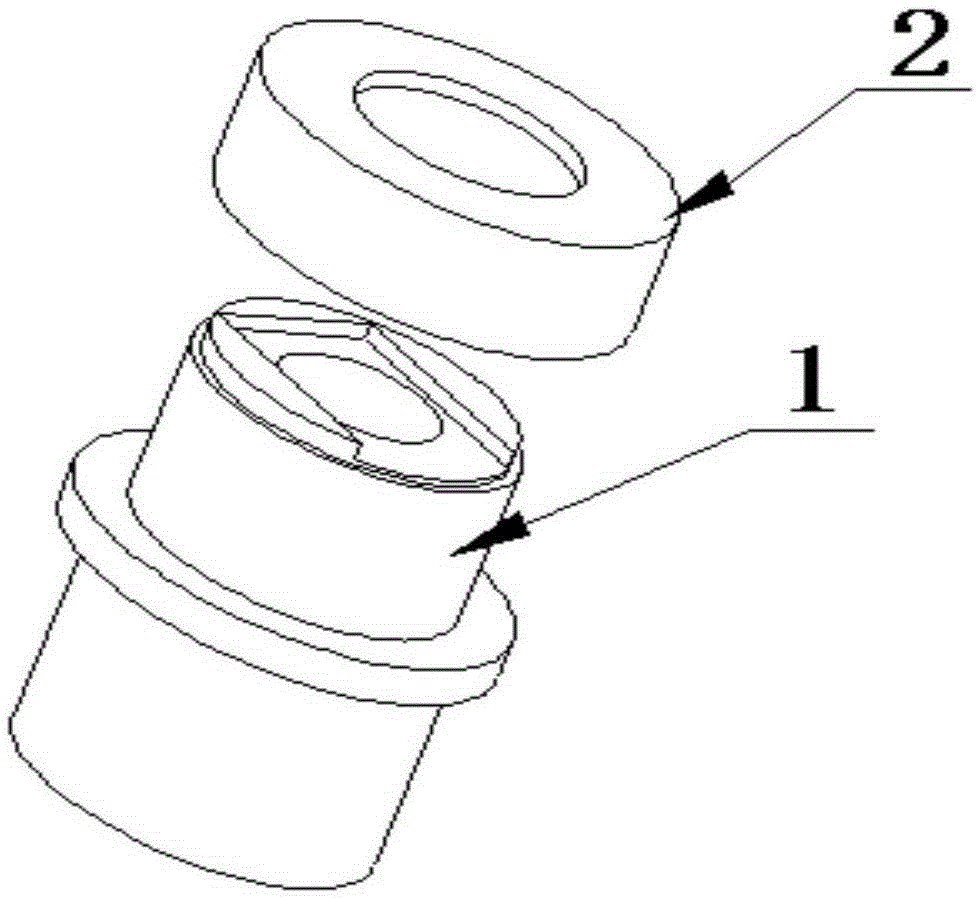

[0010] see figure 1 , a lathe fixture for polygonal parts, which is composed of a connecting base 1 and a tightening nut cover 2, wherein one end of the connecting base 1 can be connected to a lathe chuck, and the other end has a hole with an external thread, and the end face of the hole has A polygonal slot that matches the shape of the polygonal part; the tightening nut cover 2 is a cup-shaped structure that can be threaded with the connecting base 1 to compress the polygonal part, and has a through hole on the bottom surface.

[0011] The outer surface of the connection base 1 has a limiting boss.

[0012] The using method of the present invention is:

[0013] Fixing fixture: First, fix one end of the connection base 1 on the three-jaw chuck of the lathe.

[0014] Clamping the parts: put the parts into the groove of the connecting base 1 with the square fit of the parts, and tighten the tightening nut c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com