Waste bottle recovery device and recovery method thereof

A recovery device and recovery method technology, applied in the waste bottle recovery device and its recovery field, can solve problems such as difficult identification, easy broken waste bottles, glass gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

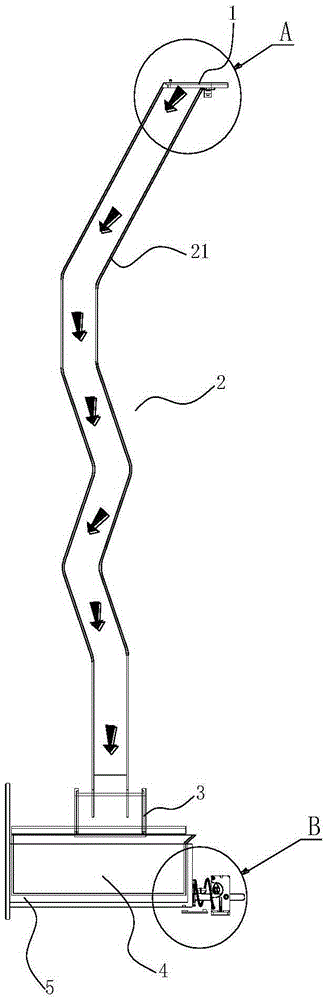

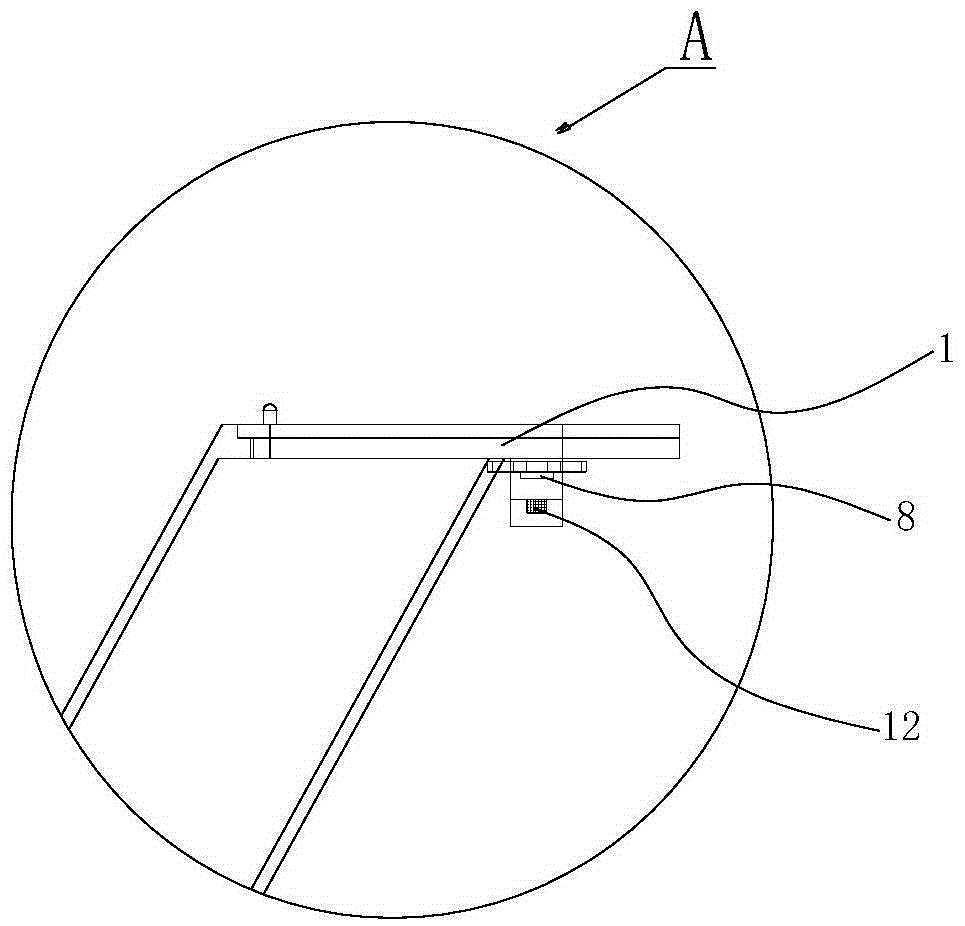

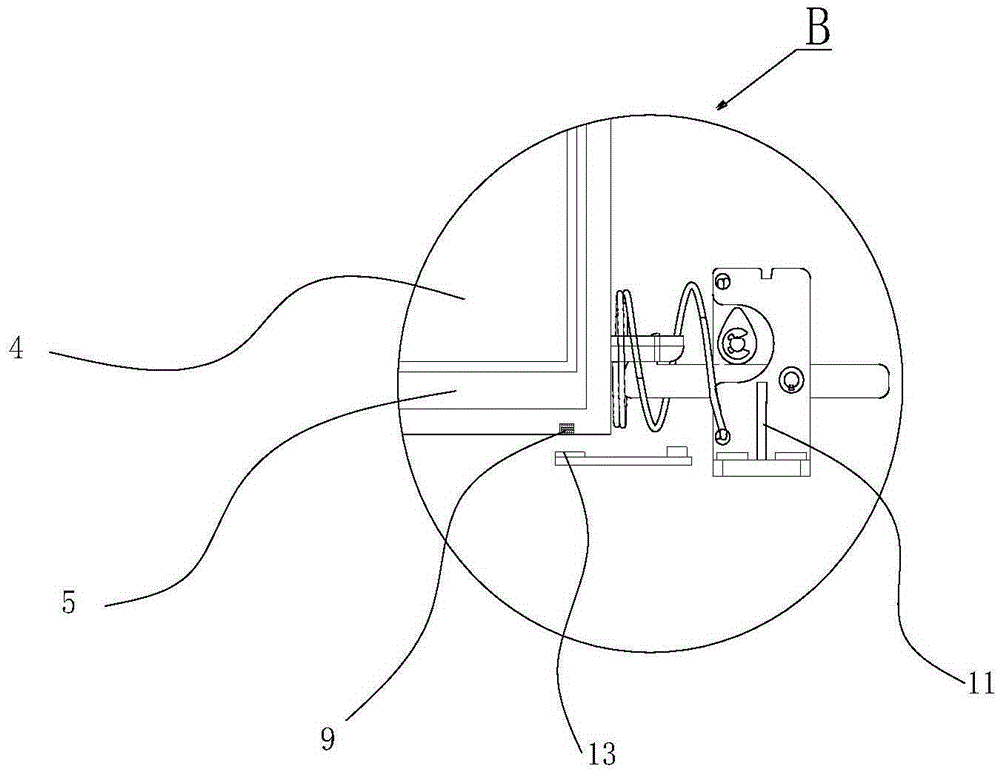

[0034] see Figure 1 to Figure 5 , The present invention provides a waste bottle recovery device, which includes a microprocessor 6, an induction module 7, a pipeline 2, a waste bottle collection box 4 and a drawer 5. The pipe 2 has a first opening and a second opening, and the waste bottle collection box 4 matches the drawer 5 . The drawer 5 includes a bottom plate and four side plates vertically arranged on the bottom plate, and the four side plates are formed by enclosing in turn, that is, an opening is left on the top surface of the drawer 5 . The waste bottle collecting box 4 comprises a base plate and four side plates vertically arranged on the base plate. The waste bottle collection box 4 is put into the drawer 5 through the opening of the drawer 5 or removed from the drawer 5 . The waste bottle recycling device also includes a mouth cover 1, which is used to close the first opening.

[0035] When in use, open the mouth cover 1 to expose the first opening, place the ...

Embodiment 2

[0045] see Figure 4 and Figure 5The difference between the present embodiment and the first embodiment is that the sensing module 7 of the present embodiment selects an ultrasonic detection element or an infrared sensor. In this embodiment, the detection principle of the ultrasonic detection element and the infrared sensor is a known technology, and it can be set with The inner wall of the pipe 2 is not necessarily arranged on the receiving portion 3 .

[0046] Correspondingly, the present invention also provides a waste bottle recovery method, which is applied to the waste bottle recovery device of the present invention, see Figure 4 , including the following steps:

[0047] Step S1: The microprocessor judges whether the first Hall switch on the first opening of the pipeline is turned on, if so, execute step S2, otherwise, repeat this step;

[0048] Step S2: The microprocessor judges whether the second Hall switch on the waste bottle collection box is off. If so, execut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com