a framework robot

A robot and frame technology, applied in the direction of conveyors, manipulators, conveyor objects, etc., can solve the problems of high labor intensity, irregular output of output materials, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

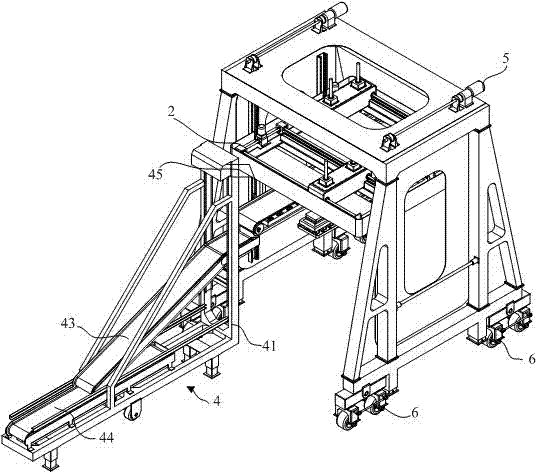

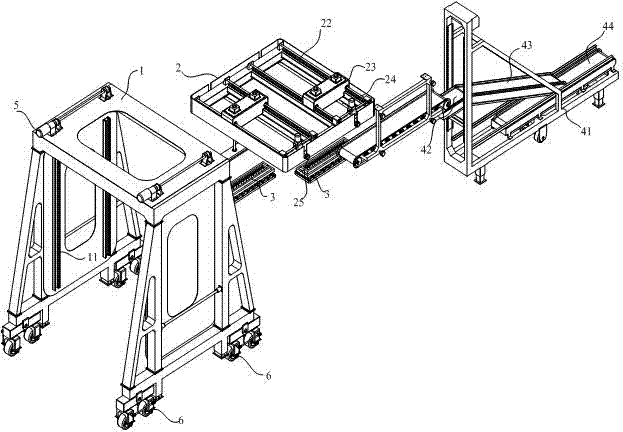

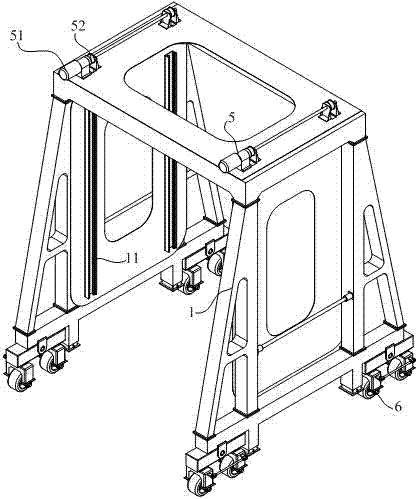

[0015] see Figure 1-Figure 6 As shown, the present invention proposes an embodiment of a frame robot, including a control device, a basic frame 1, a lifting platform 2, a manipulator 3 and a height-adjustable conveying line 4 for receiving materials, and the lifting platform 2 is arranged on the Inside the base frame 1 and slidably connected with the base frame 1, the manipulator 3 includes a bracket 31, a plurality of grippers 32 symmetrically arranged on the bracket 31, and a driving element 33 for driving at least one or a pair of grippers. The base frame 1 is provided with a lifting device 5 for driving the lifting platform 2, the lifting device 5 is fixedly connected with the lifting platform 2, and the lifting platform 2 includes a platform support 21, which is arranged on the platform support 21 The inner horizontal slide rail 22, at least one set of lifting m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap