Unloading device

A technology of unloading device and hanger, which is applied in the direction of transportation and packaging, mechanical equipment, load hanging components, etc. It can solve the problems of different sizes, the safety and work efficiency cannot be effectively guaranteed, and the loss of the net bag is large. Simple operation, solving the problem of bulk material loading and unloading, and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

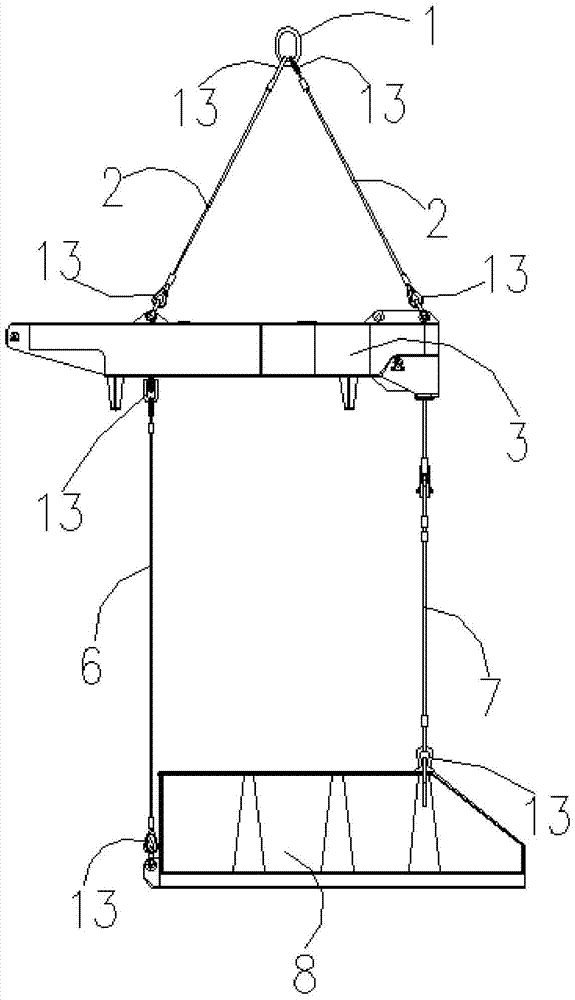

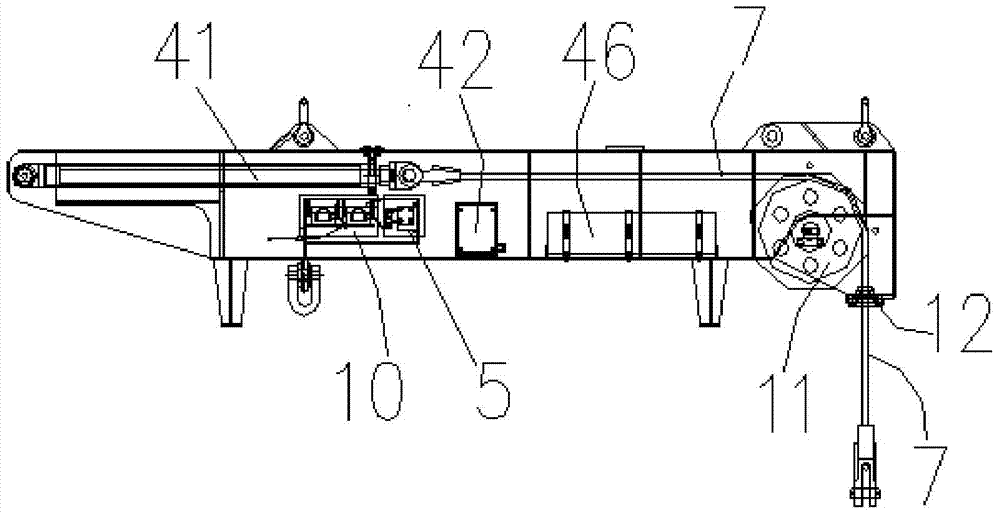

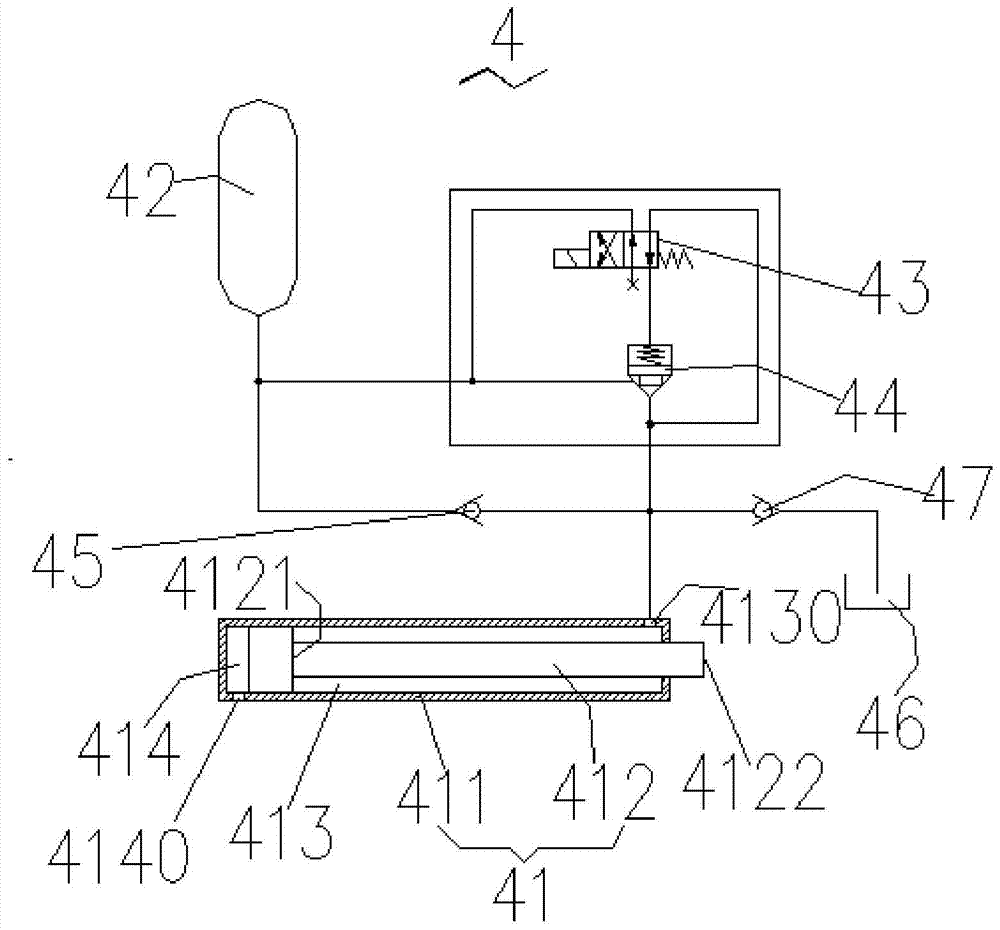

[0040] The present invention is a kind of unloading device, comprises the suspension ring 1 at the top, at least two suspension ropes 2 connected with suspension ring 1 and the hanger 3 transversely connected to the bottom end of at least two suspension ropes 2, the hanger 3 is provided with A hydraulic system 4 and a hydraulic control system 5, the hydraulic system 4 includes a hydraulic cylinder 41 and an energy storage device 42, the hydraulic control system 5 controls the circulation of hydraulic oil between the hydraulic cylinder 41 and the energy storage device 42, and the hydraulic cylinder 41 includes a cylinder Body 411 and piston rod 412, the piston rod 412 includes a first end 4121 located in the cylinder 411 and a second end 4122 located outside the cylinder 411, one of the piston rod 412 and the cylinder 411 circulates in the hydraulic oil The other one of the piston rod 412 and the cylinder body 411 remains stationary during the hydraulic oil circulation process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com