A non-conveying continuous steel bar automatic collection and bundling integration equipment

An automatic collection and continuous technology, which is applied to the parts and packaging of strapping machines, can solve the problems of manual pulling out of unloading vehicles, quantity counting errors, troublesome steel bar collection, etc., to achieve convenient counting, increase collection speed, and avoid The effect of rebar crossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

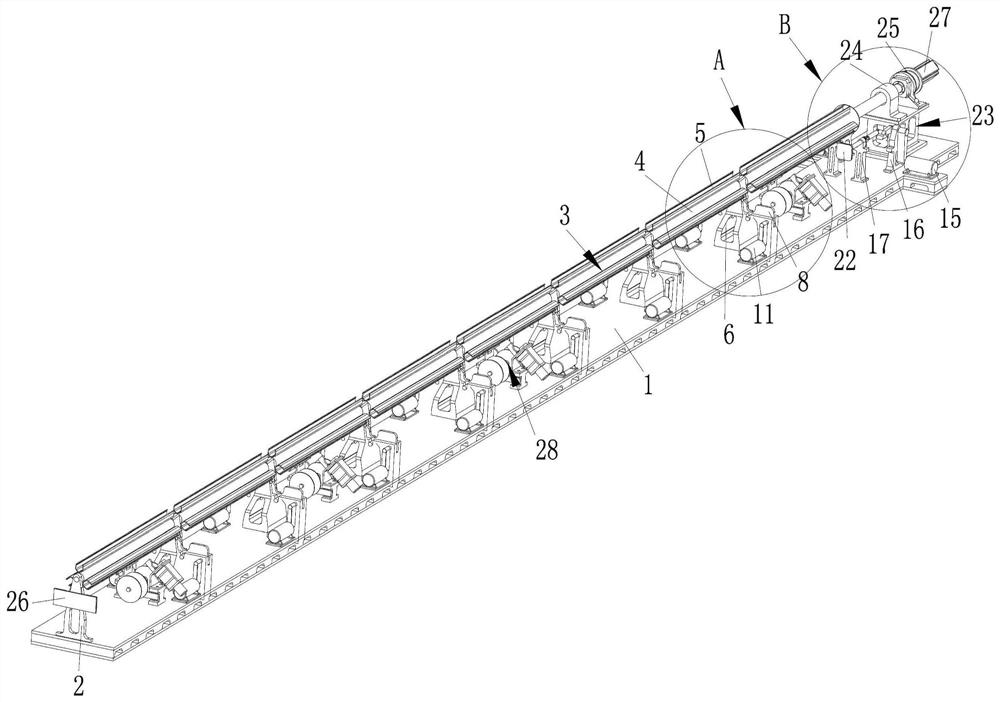

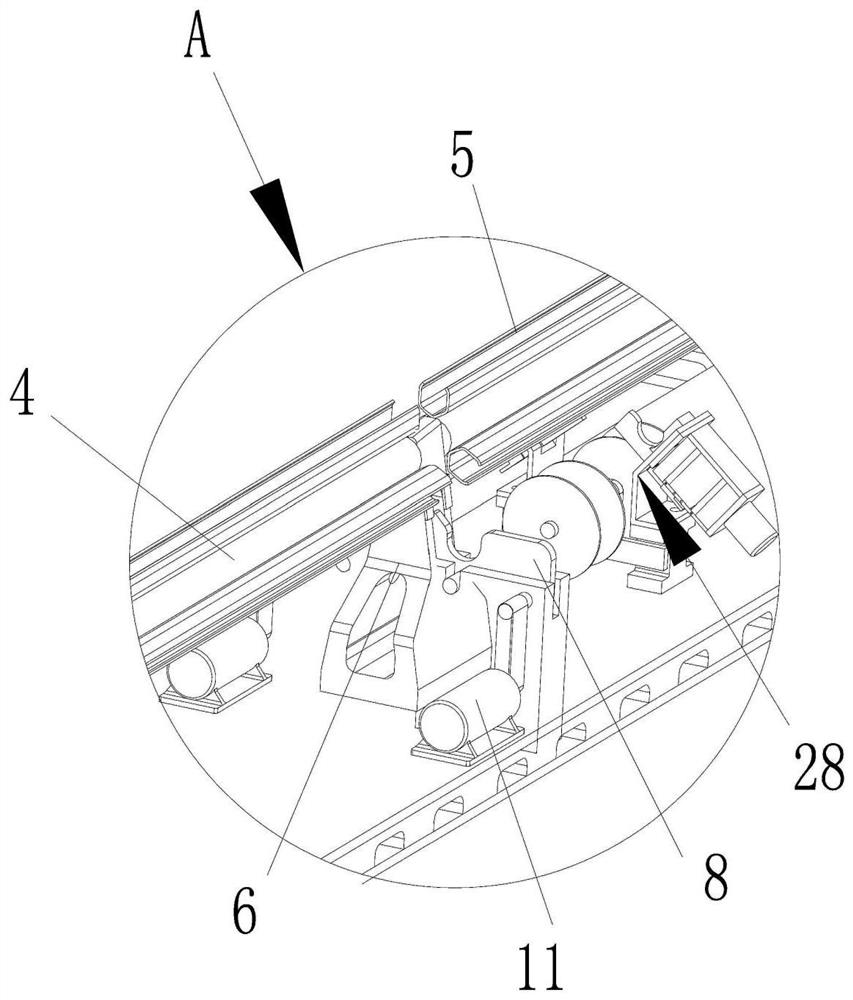

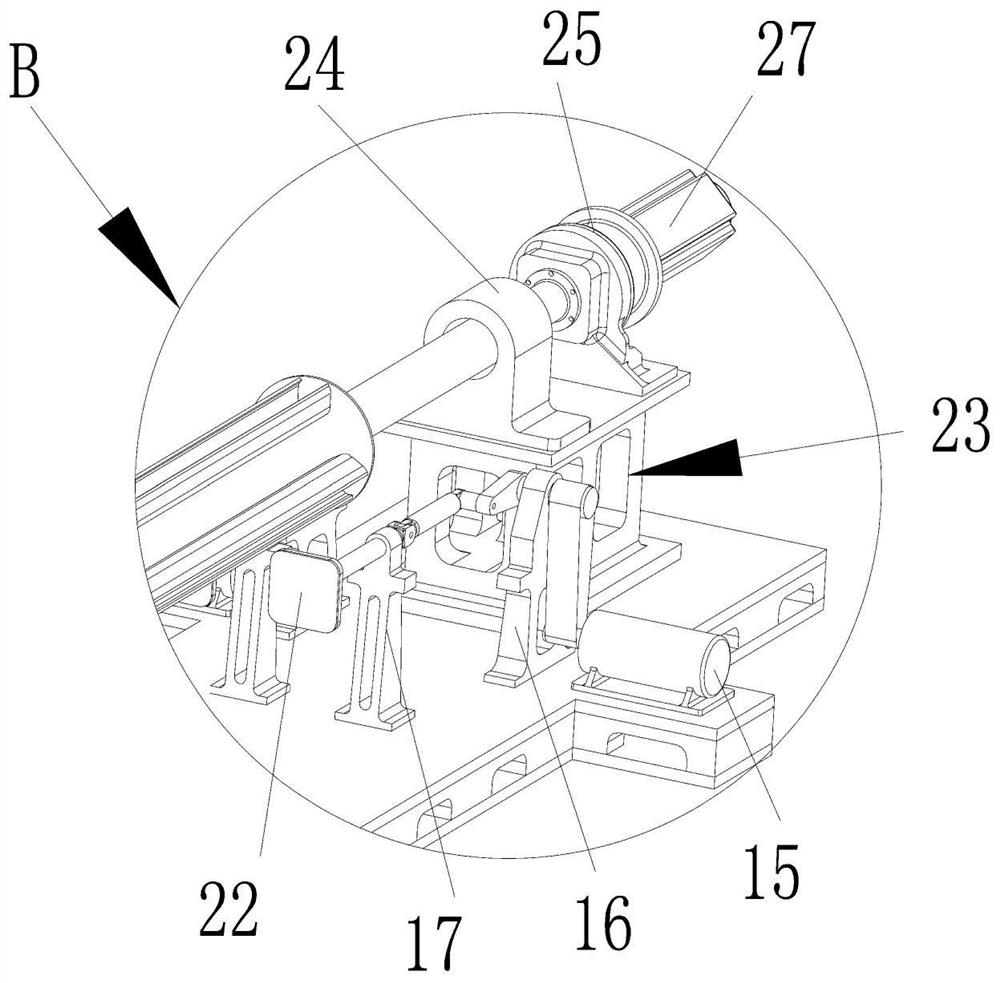

[0029] Such as Figure 1 to Figure 5 As shown, a non-conveying continuous steel bar automatic collection and bundling integration equipment includes a bottom plate 1, a driving device is provided on the bottom plate 1, and the output end of the driving device is connected with a material receiving device for connecting cut steel bars. device, the other end of the material receiving device is connected with a connecting frame 2, and the side of the material receiving device is correspondingly provided with a turning device and a bundling device 28, and a plurality of steel bars can be aligned between the driving device and the material receiving device. When in use, the present invention is arranged under the steel bar cutting equipment. When the steel bar is cut off, it falls on the material receiving device. At the same time, the drive motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com