A method for preparing k424 casting superalloy by using k417g and dz417g alloy return material

A technology of superalloy and return material, applied in the field of superalloy preparation, can solve the problems that the alloy return material cannot be used according to the original grade, destroy the ecological environment, waste resources, etc., and achieve the goal of reducing production costs, improving the ecological environment, and reducing waste of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method of using K417G and DZ417G alloy return materials in this embodiment to prepare K424 cast superalloy is carried out according to the following steps:

[0025] The K417G alloy return material and the DZ417G alloy return material produced in the casting production process were respectively loaded into the drum for tumbling treatment. The tumbling treatment time was 6.5 hours, and then the surfaces of the two alloy return materials were blasted separately, and then dried with a dry Compressed air blows the surface of the two alloy return materials piece by piece, and obtains the purified K417G alloy return material and DZ417G alloy return material;

[0026] (2) Smelting return materials and castable ingots:

[0027] A 500kg semi-continuous vacuum induction melting furnace is used to melt the purified K417G alloy return material and DZ417G alloy return material respectively. When the temperature is less than or equal to 0.67Pa, start to melt with electricity. Fir...

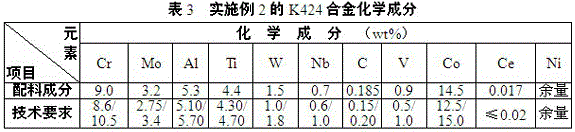

Embodiment 2

[0036] The method of using K417G and DZ417G alloy return materials in this embodiment to prepare K424 cast superalloy is carried out according to the following steps:

[0037] The K417G alloy return material and the DZ417G alloy return material generated during the casting production process were put into the drum for tumbling treatment, and the tumbling treatment time was 7 hours, and then the surfaces of the two alloy return materials were blasted separately, and then dried Compressed air blows the surface of the two alloy return materials piece by piece, and obtains the purified K417G alloy return material and DZ417G alloy return material;

[0038] (2) Smelting return materials and castable ingots:

[0039] A 500kg semi-continuous vacuum induction melting furnace is used to melt the purified K417G alloy return material and DZ417G alloy return material respectively. When the temperature is less than or equal to 0.67Pa, start to melt with electricity. First, heat the alloy r...

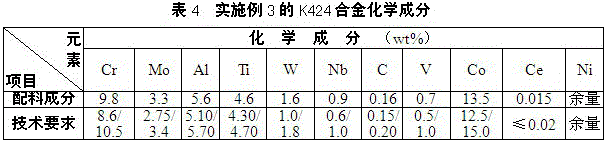

Embodiment 3

[0047] The method of using K417G and DZ417G alloy return materials in this embodiment to prepare K424 cast superalloy is carried out according to the following steps:

[0048] The K417G alloy return material and the DZ417G alloy return material generated during the casting production process were put into the drum for tumbling treatment, and the tumbling treatment time was 7.5 hours, and then the surfaces of the two alloy return materials were blasted separately, and then dried Compressed air blows the surface of the two alloy return materials piece by piece, and obtains the purified K417G alloy return material and DZ417G alloy return material;

[0049] (2) Smelting return materials and castable ingots:

[0050] A 500kg semi-continuous vacuum induction melting furnace is used to melt the purified K417G alloy return material and DZ417G alloy return material respectively. When the temperature is less than or equal to 0.67Pa, start to melt with electric power. First, heat the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com