Two-degree freedom thermal fatigue test device used for metal bellows of vehicle exhaust system

A technology of automobile exhaust system and metal bellows, which is applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems that can not truly reflect the movement of bellows, increase design cost and test cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

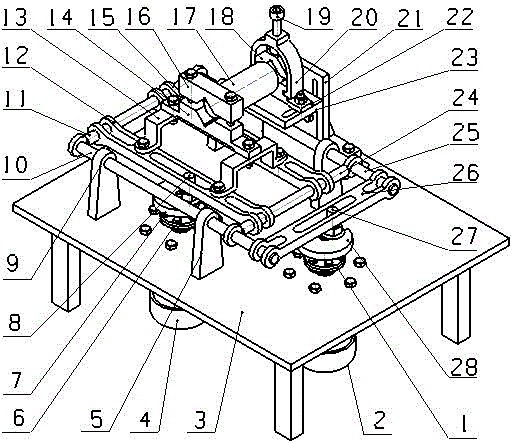

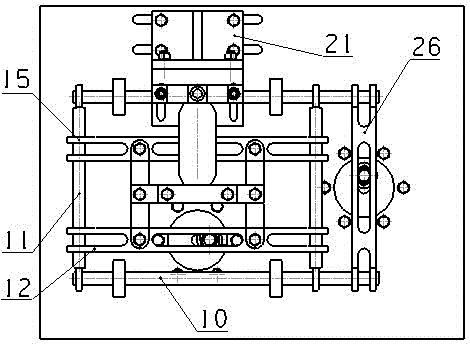

[0014] The device of the present invention mainly includes three parts: a driving part, a transmission part and a clamping part. Among them, the driving part is realized by two motors, which control the radial and axial movements of the metal bellows through the two motors. The device can realize the radial and axial combined movement of the bellows while realizing the radial or axial independent movement of the bellows.

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

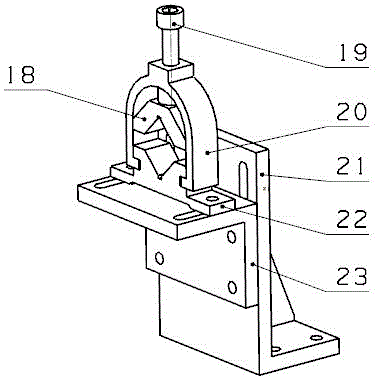

[0016] refer to figure 1 , the overall structure of the device is connected: the fixed end of the metal bellows is completely fixed by the clamping mechanism (18) (19) (20) (22), and the moving end is fixed on the vibration mechanism by the clamping mechanism (14) (16) . The drive motor (2) (4) is fixed under the test bench (3), and drives the eccentric rotation mechanism (7) and (28) respectively through the coupling (1) (6), wherein the eccentric rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com