Thermal fatigue testing machine for metal corrugated pipe of automobile exhaust system

A technology of automobile exhaust system and metal bellows, which is applied in the field of thermal fatigue testing machines, can solve the problems of increasing design cost and test period, and cannot truly reflect the movement of bellows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

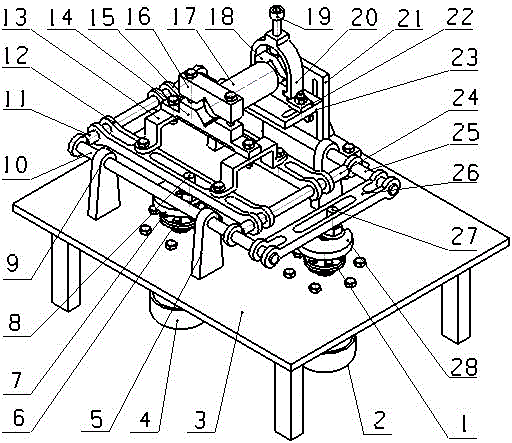

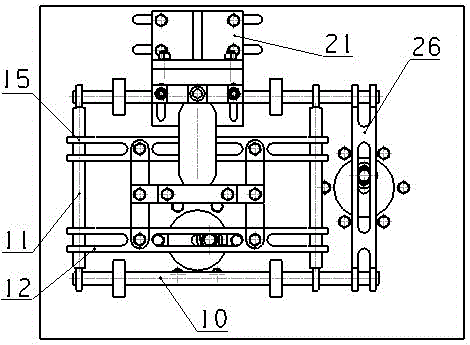

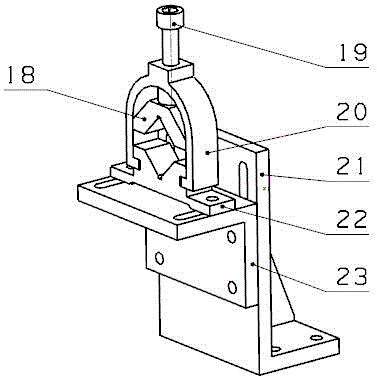

[0014] The testing machine is composed of two modules, the mechanical structure and the electric control system. The mechanical structure module includes three parts: the driving part, the transmission mechanism and the clamping mechanism. The electronic control system module includes a measurement and control interface, an industrial computer, and a motor controller. When the testing machine is working, the user sets the movement direction and frequency of the bellows through the measurement and control interface, and the industrial computer outputs control commands to the drive system to control the thermal fatigue testing machine to perform thermal fatigue tests according to the operating conditions set by the measurement and control interface. The machine collects the actual motion state parameters of the bellows thermal fatigue test and displays them on the measurement and control interface. The testing machine can realize the radial and axial independent and combined mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com