Mobile terminal shell and manufacturing method therefor

A technology of mobile terminal and manufacturing method, which is applied in the direction of casing/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, electrical components, etc., and can solve the problems of plastic and metal peeling, design difficulties, appearance and complete machine Reliability degradation and other problems, to achieve the effect of reliable fixed connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present disclosure will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present disclosure, and structural, method, or functional changes made by those skilled in the art based on these embodiments are all included in the protection scope of the present disclosure.

[0026] The terminology used in the present disclosure is for the purpose of describing particular embodiments only, and is not intended to limit the present disclosure. As used in this disclosure and the appended claims, the singular forms "a", "the", and "the" are intended to include the plural forms as well, unless the context clearly dictates otherwise. It should also be understood that the term "and / or" as used herein refers to and includes any and all possible combinations of one or more of the associated listed items.

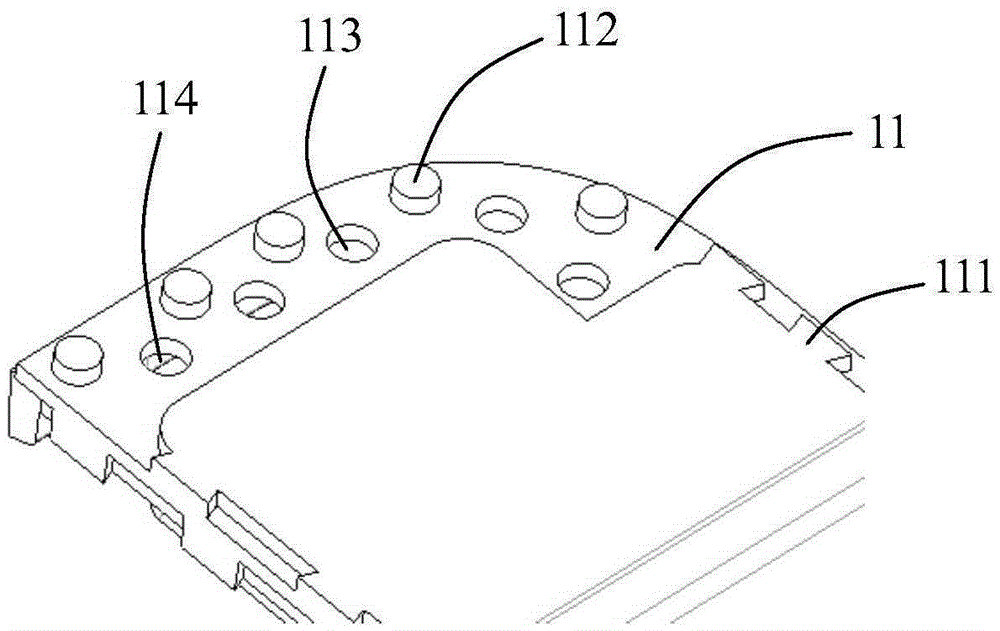

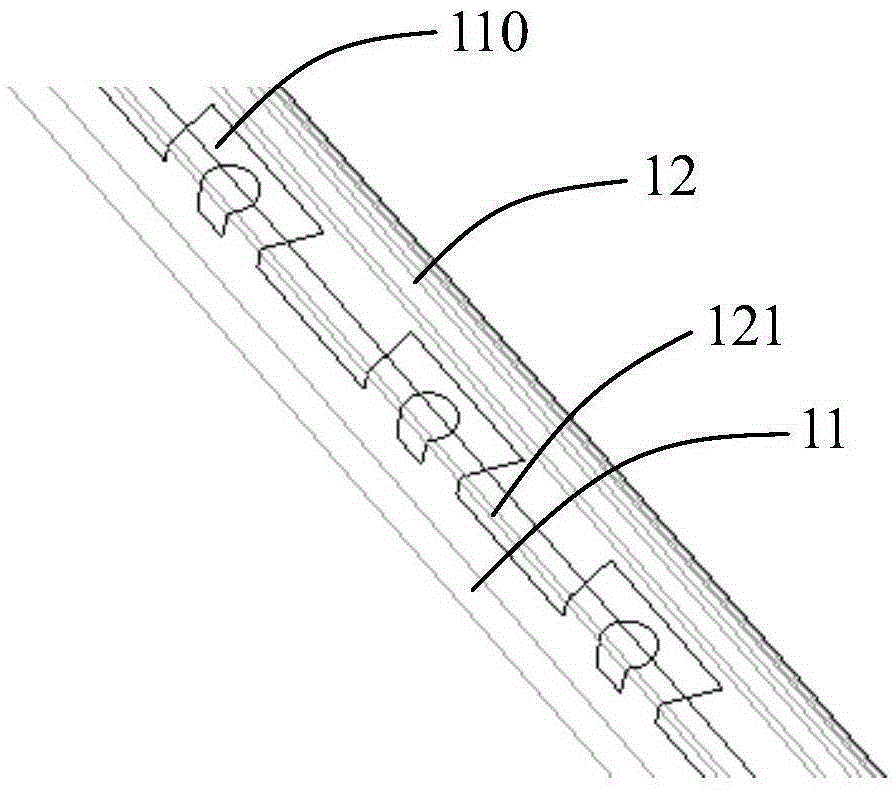

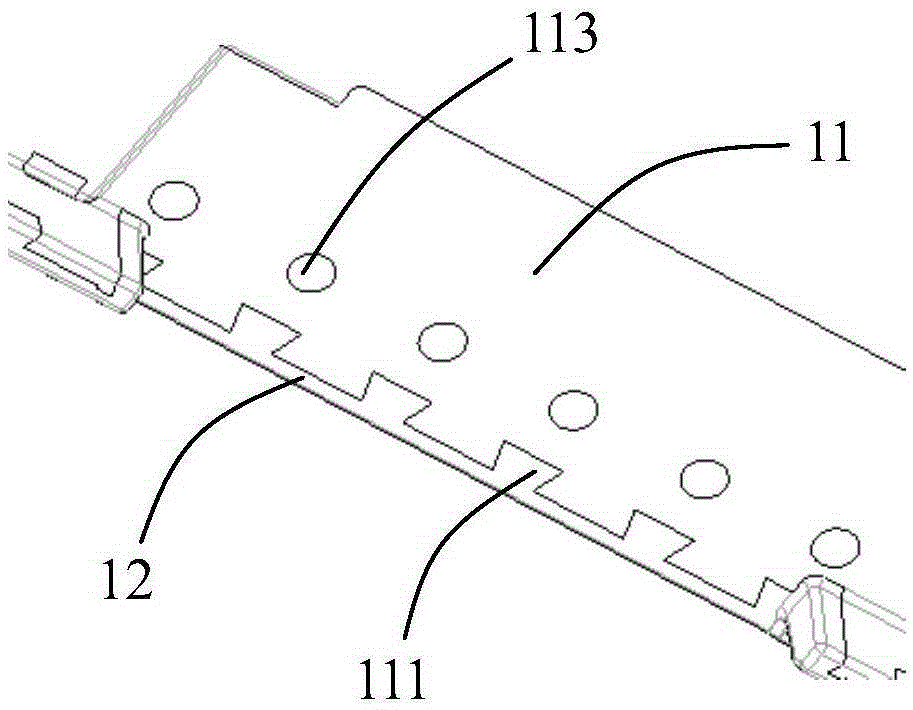

[0027] Such as figure 1 and figure 2 as shown, figure 1 It is a partial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com