Wind power generating unit and vertically stacked wind power generation system

A rotating force and impeller technology, which is applied in the field of wind power generation units and vertical stacked wind power generation systems, can solve the problems of low wind energy density, reduced wind continuity, and changes in wind direction and speed at any time, so as to improve power generation efficiency and improve wind direction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Referring to the accompanying drawings, the wind power generation unit and the vertically stacked wind power generation system according to the preferred embodiments of the present invention will be described in detail. In this specification, the same or similar reference numerals are attached to the same or similar configurations even if they are mutually different examples, and the description thereof will be replaced by the first description.

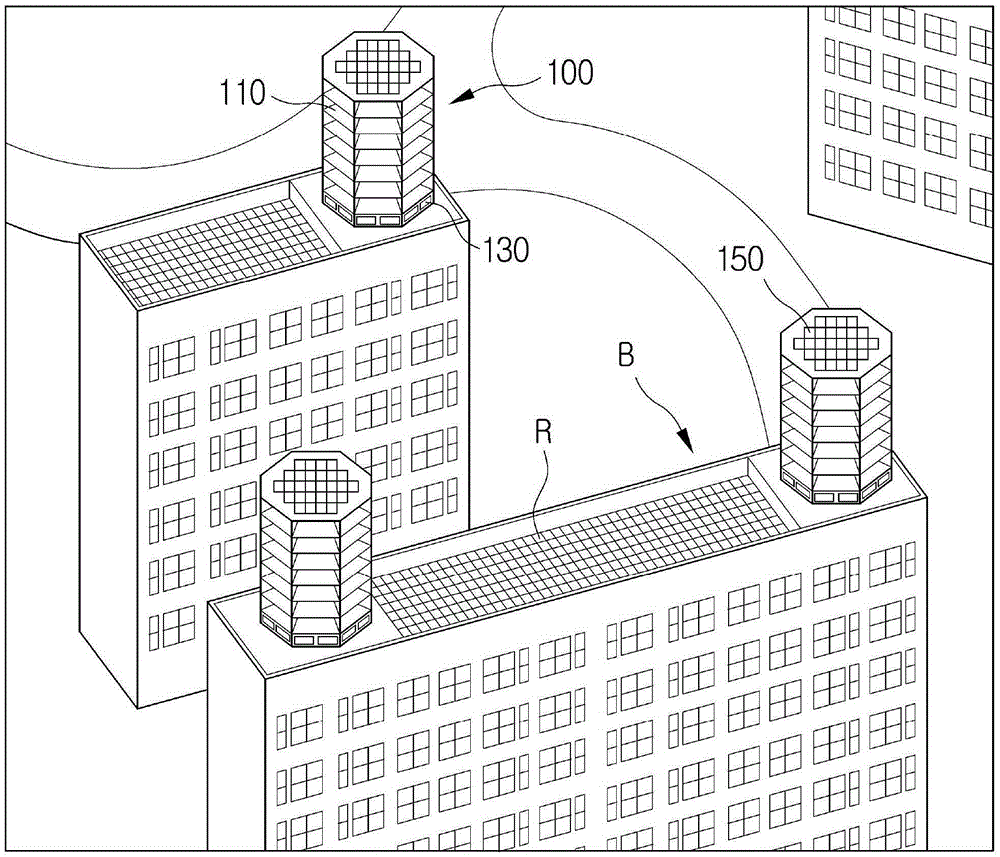

[0026] figure 1 It is a perspective view showing an installed state of a vertically stacked wind power generation system 100 according to an embodiment of the present invention.

[0027] Referring to this figure, the vertically stacked wind power generation system 100 may include a driving machine 110 , a generator 130 and accessories 150 .

[0028] The driving machine 110 is configured to generate rotational force upon receiving wind. The driver 110 can be a single layer, or can be stacked to form multiple layers as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com