A kind of ink coating method using lens edge ink coating equipment

A lens and ink coating technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems affecting product quality and appearance, and achieve the effects of convenient ink coating operation, high work efficiency and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

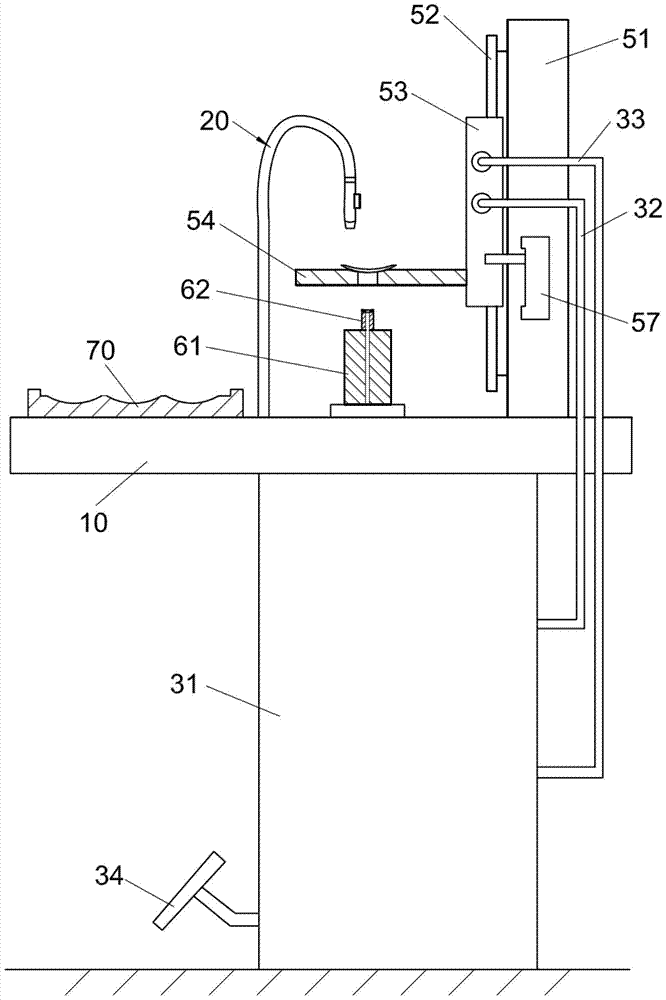

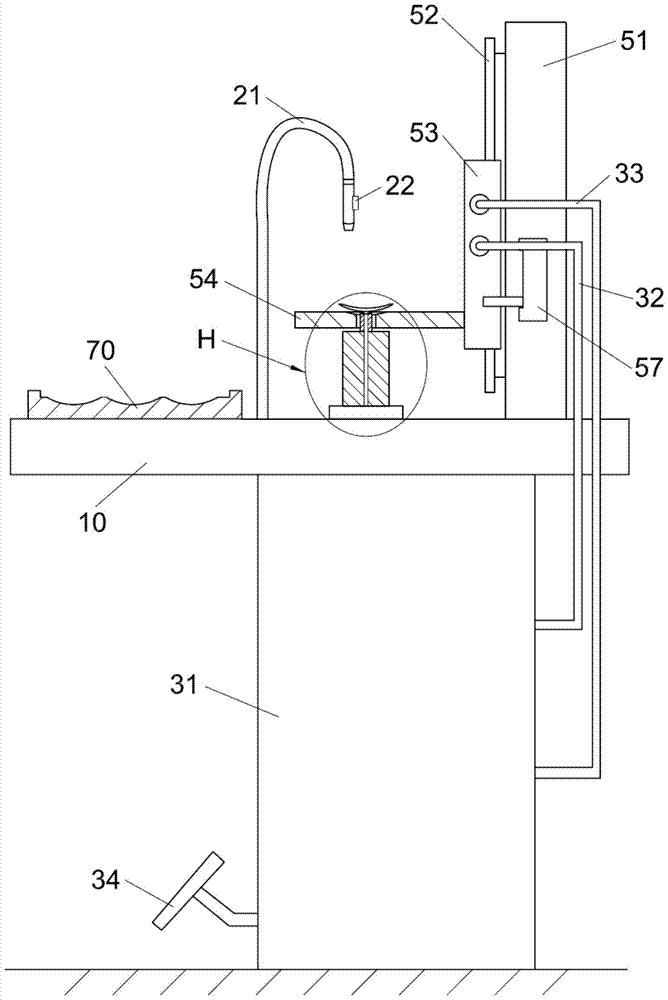

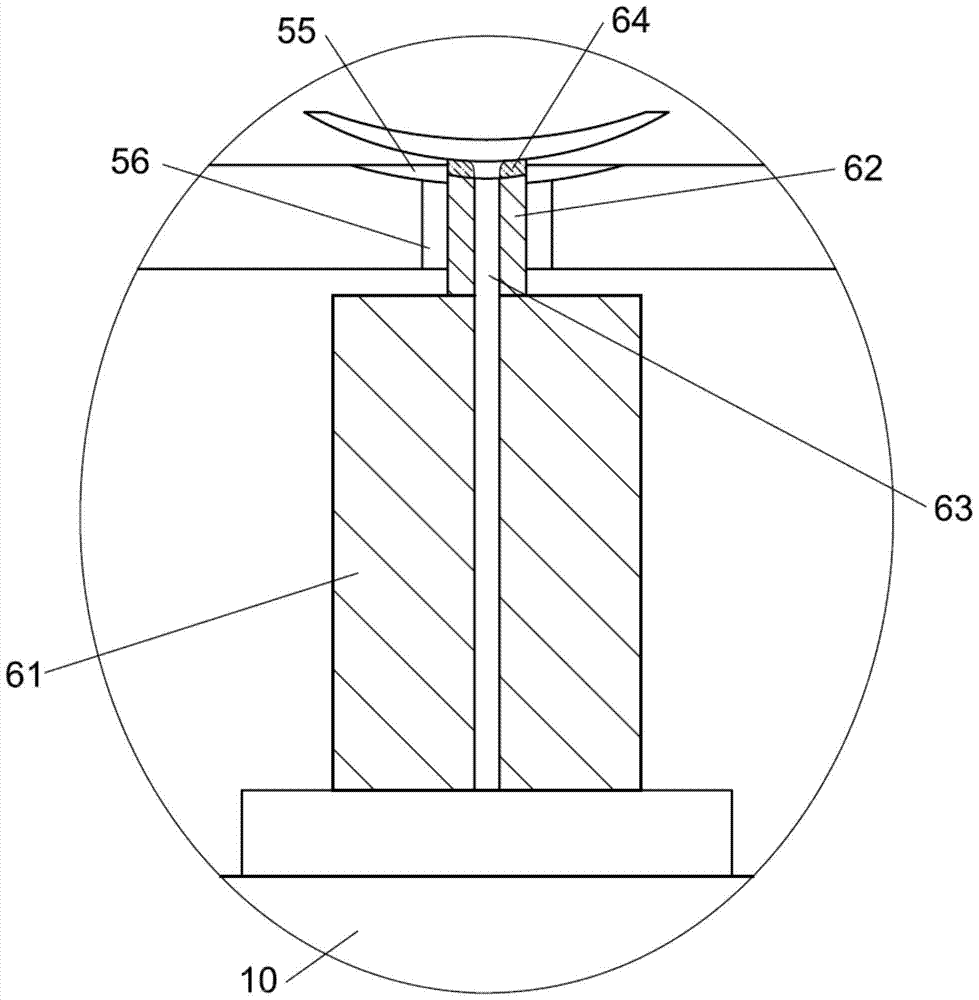

[0021] The invention provides a lens edge ink coating equipment, as attached figure 1 And attached figure 2 As shown, it includes a desktop 10, a workpiece moving device 20, a pneumatic control box 31, an ink pen 40, and a base 51, a rotating member 61 and a swing plate 70 arranged on the desktop 10, and a guide rail 52 is fixedly connected to the base 51. A slide block 53 is arranged on the guide rail 52 , and a loading platform 54 is fixedly connected to the slide block 53 . as attached image 3 As shown, the upper surface of the stage 54 is provided with a spherical groove 55 for lens positioning, and a through hole 56 is arranged below the spherical groove 55. The spherical groove 55 is coaxial with the rotating member 61, and the upper surface of the rotating member 61 is fixedly connected. For the ejector 62 that lifts the lens away from the spherical groove 55 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com