bv line bending stamping die with combined upper die

A stamping die and combined technology, which is applied in the field of BV line bending stamping die, can solve the problems of difficulty in matching distribution boxes, unfavorable production cost control, and different shapes of BV lines, so as to achieve simple structure and avoid BV lines Misalignment, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

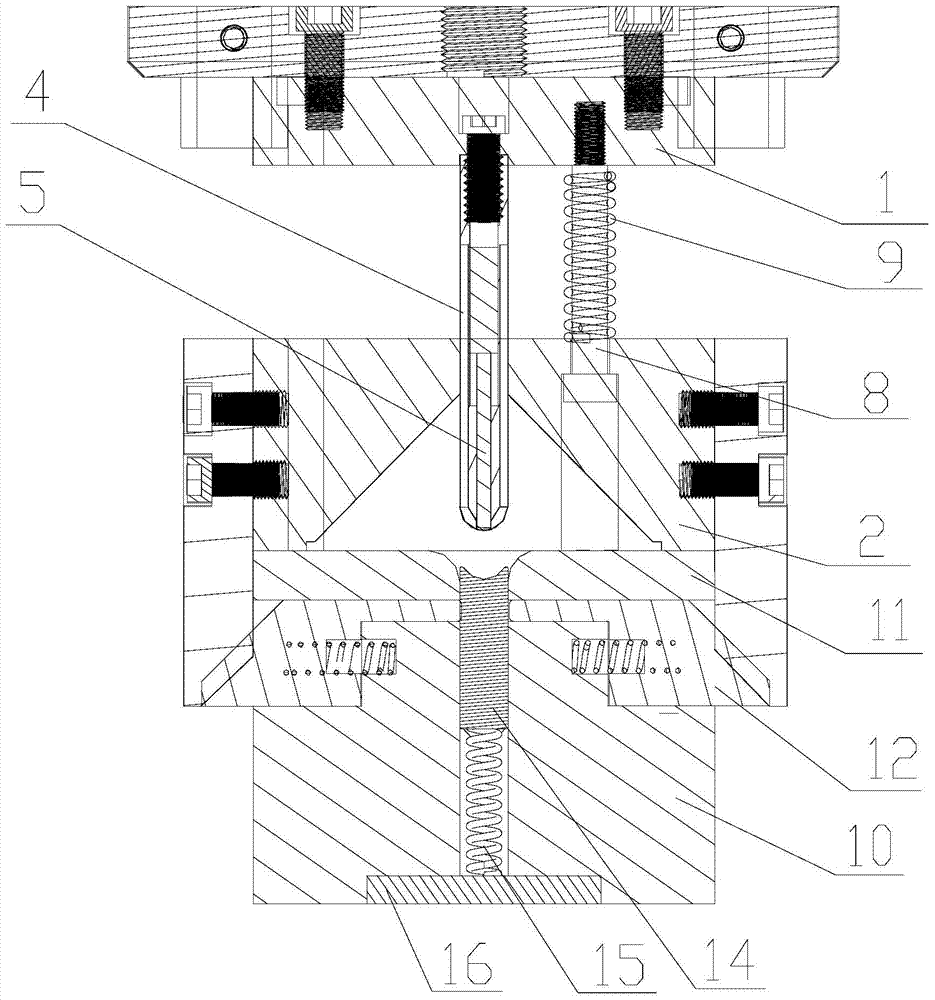

[0029] In this embodiment, a BV line bending stamping die with a combined upper die, its overall structure is as follows figure 1 As shown, it includes matching upper mold and lower mold. The top of the upper mold is connected to the stamping equipment through the upper mold mounting plate, and the bottom of the lower mold is connected to the stamping equipment through the lower mold mounting plate. Among them, the existing stamping equipment is selected for Just install it.

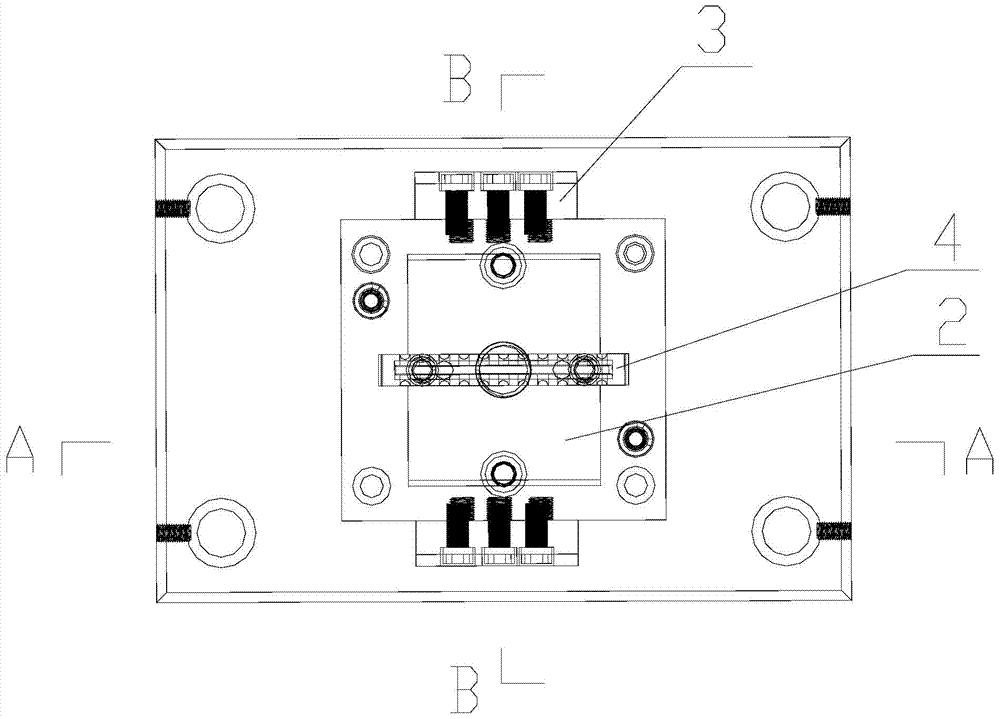

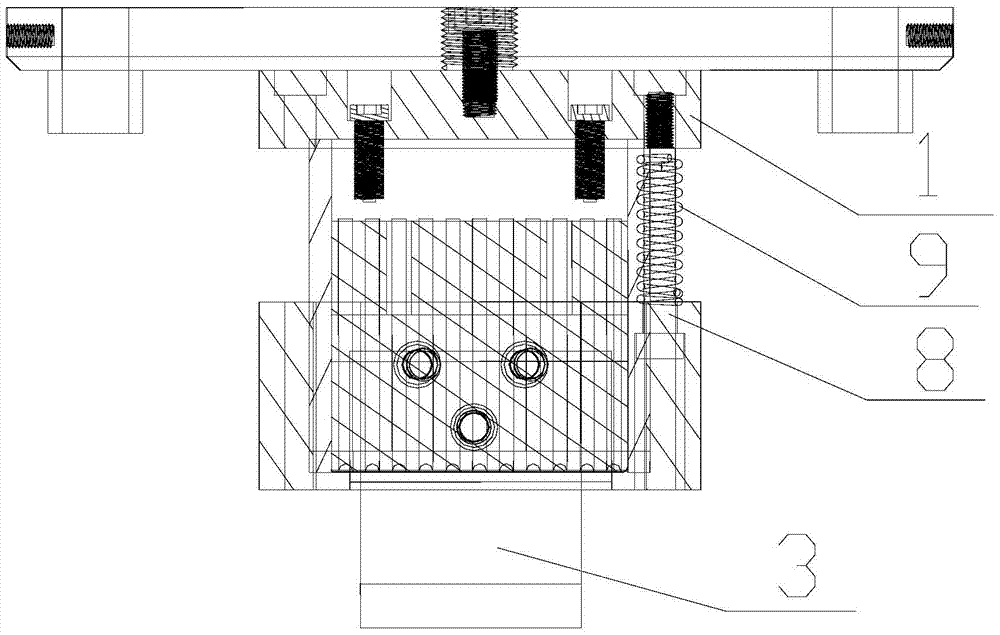

[0030] Such as Figure 2~4 As shown, the upper mold includes the upper mold pressing needle assembly, the upper mold pressing needle fixing block 1, the BV line pressing block 2, the side stress pressing plate 3 and the upper mold pressing needle guide rod assembly, and the upper part of the upper mold pressing needle assembly is connected with the upper mold pressing needle fixing block , the lower part of the upper mold pressing needle assembly is located in the BV line pressing block, and the upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com