Assembling device and method for shaft connection bearing of engine cooling water pump

A technology for engine cooling and bearing assembly, applied in transportation and packaging, metal processing, metal processing equipment, etc., can solve the problems of low efficiency of press-fit bearings, low yield, low assembly efficiency, etc., and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

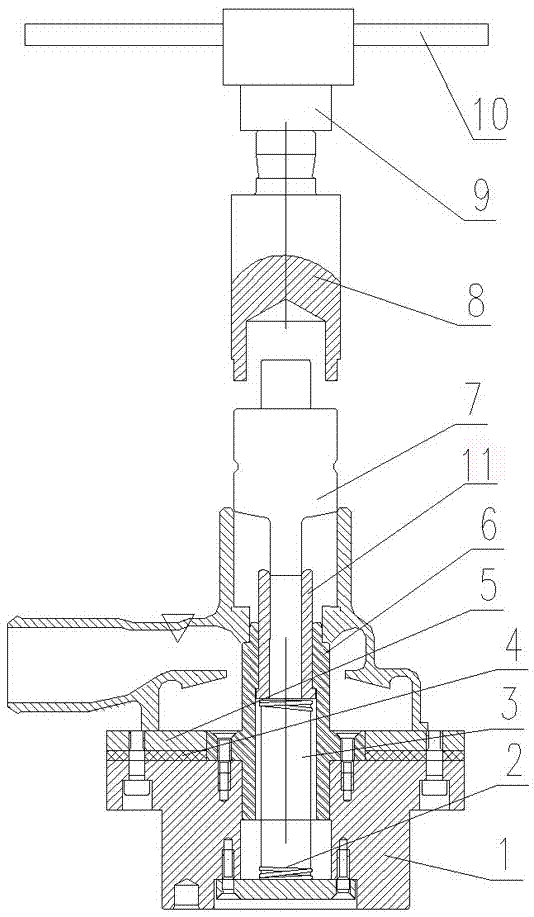

[0028] Such as figure 1 As shown, an engine cooling water pump shaft-connected bearing assembly device includes a worktable 1, a clamp body 5 is provided on the workbench 1, a press-fitting mechanism is provided on the clamp body 5, and a bearing is provided on the workbench 1. Righting the guiding and positioning mechanism.

[0029] The bearing righting guide positioning mechanism includes a guide sleeve 6 arranged on the workbench and a guide head 11 located in the guide sleeve coaxial with the telescopic rod of the press-fitting mechanism, and the guide head 11 is connected with the clip body through an elastic mechanism.

[0030] The elastic mechanism includes a guide rod arranged under the guide head and a spring 2 or cylinder positioned under the guide rod 3, and the spring plays a role in supporting the guide rod and the guide head.

[0031] The guide head is slidingly matched with the bearing shaft, and the guide head acts as a guide for the bearing shaft and prevents...

Embodiment 2

[0047] Such as figure 1 As shown, an engine cooling water pump shaft-connected bearing assembly device includes a worktable 1, a clamp body 5 is provided on the workbench 1, a press-fitting mechanism is provided on the clamp body 5, and a bearing is provided on the workbench 1. Righting the guiding and positioning mechanism.

[0048]The bearing righting guide positioning mechanism includes a guide sleeve 6 arranged on the workbench and a guide head 11 located in the guide sleeve coaxial with the telescopic rod of the press-fitting mechanism, and the guide head 11 is connected with the clip body through an elastic mechanism.

[0049] The elastic mechanism includes a guide rod arranged under the guide head and a spring 2 or cylinder positioned under the guide rod 3, and the spring plays a role in supporting the guide rod and the guide head.

[0050] The guide head is slidingly matched with the bearing shaft, and the guide head acts as a guide for the bearing shaft and prevents ...

Embodiment 3

[0061] Such as figure 1 As shown, an engine cooling water pump shaft-connected bearing assembly device includes a worktable 1, a clamp body 5 is provided on the workbench 1, a press-fitting mechanism is provided on the clamp body 5, and a bearing is provided on the workbench 1. Righting the guiding and positioning mechanism.

[0062] The bearing righting guide positioning mechanism includes a guide sleeve 6 arranged on the workbench and a guide head 11 located in the guide sleeve coaxial with the telescopic rod of the press-fitting mechanism, and the guide head 11 is connected with the clip body through an elastic mechanism.

[0063] The elastic mechanism includes a guide rod arranged under the guide head and a spring 2 or cylinder positioned under the guide rod 3, and the spring plays a role in supporting the guide rod and the guide head.

[0064] The guide head is slidingly matched with the bearing shaft, and the guide head acts as a guide for the bearing shaft and prevents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com