Breaking spring compression device

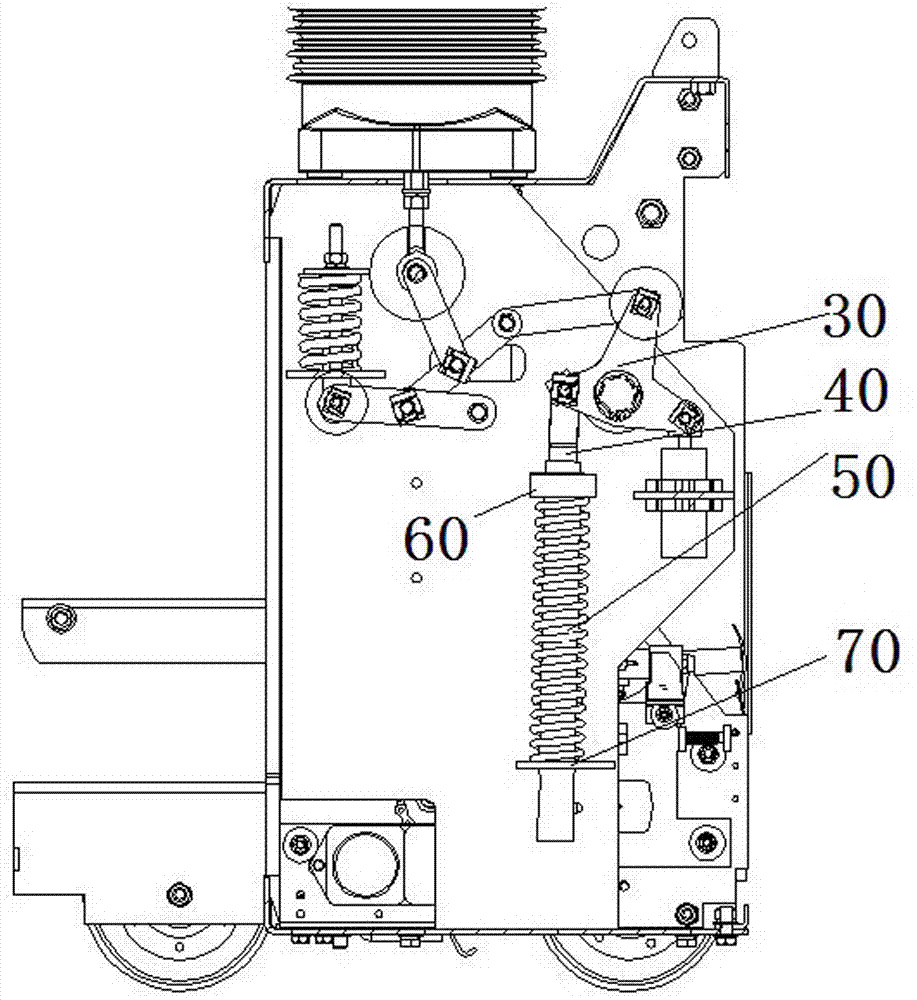

A technology of opening spring and compression device, applied in emergency protection device, emergency protection device manufacturing, electrical components and other directions, can solve the problems of inconvenient installation, low installation efficiency, hidden safety hazards in the assembly process, etc., and achieve the effect of avoiding hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

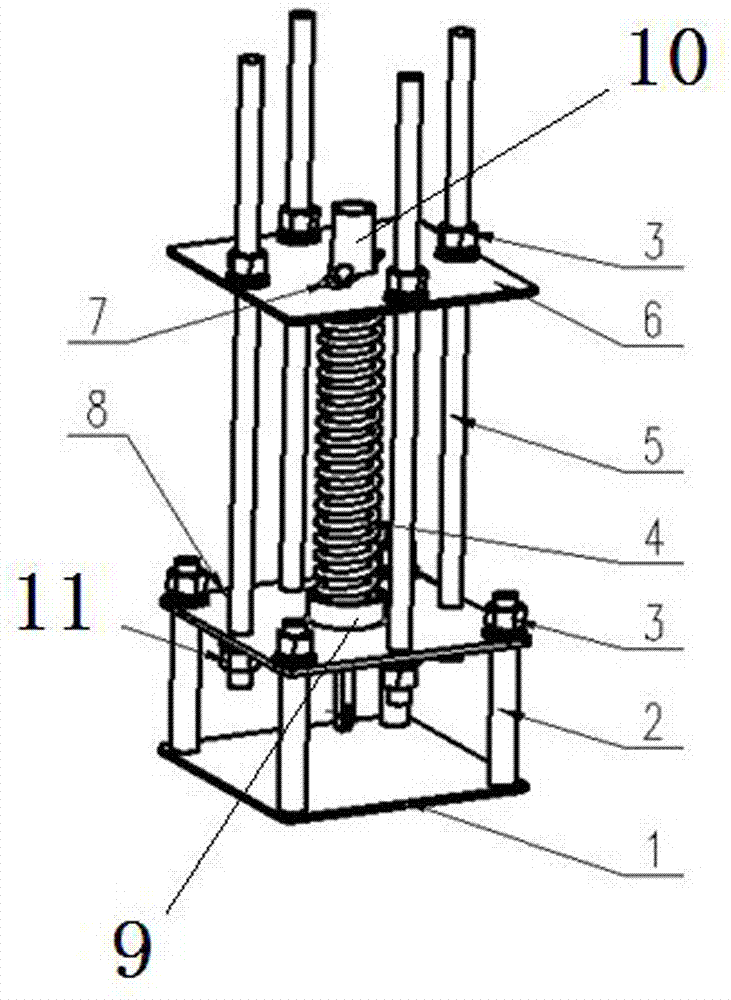

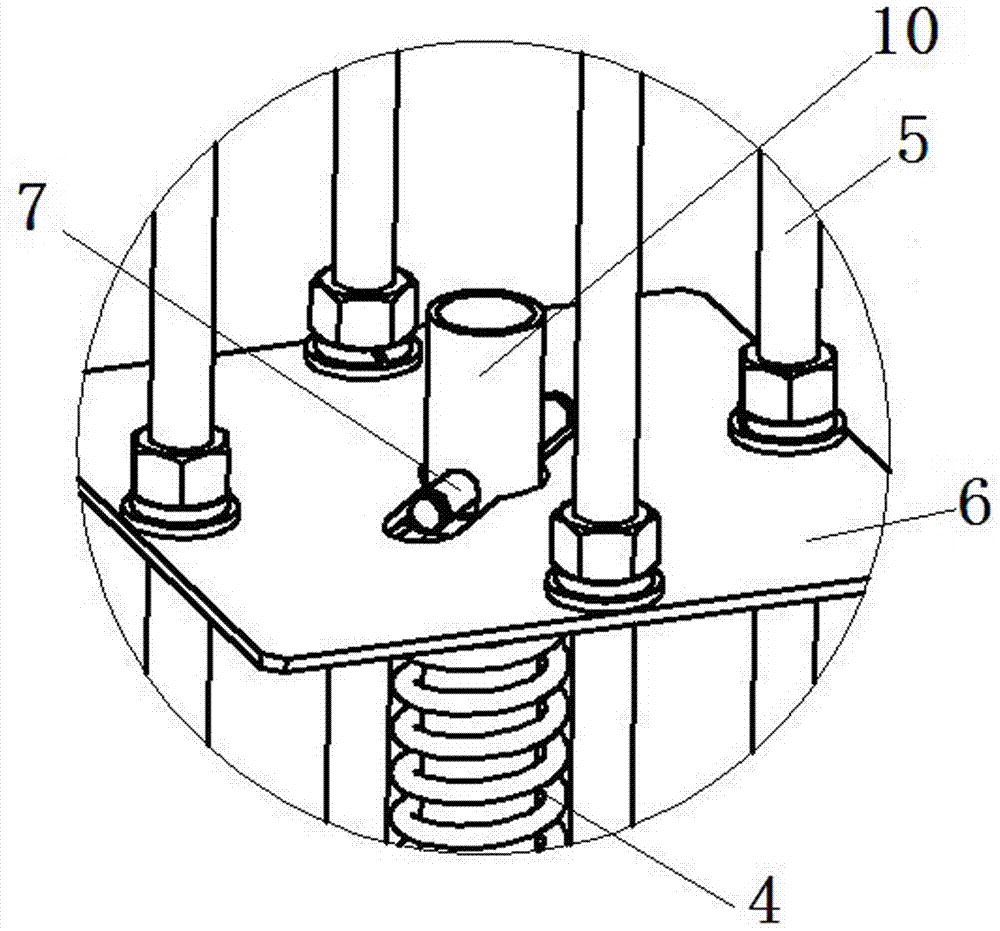

[0018] Embodiments of the opening spring compression device of the present invention: as Figure 2-5 As shown, the opening spring compression device includes a support base and a driving mechanism. The support base is provided with a limit structure for moving the spring seat 9 in the opening spring assembly to the side away from the opening spring 4. The driving mechanism It includes the driving part and the transmission part that moves in the direction of the spring seat 9 under the action of the driving part and compresses the opening spring 4. The transmission part is provided with a perforation for the pull rod 10 of the opening spring assembly to pass through. The opening spring compression device also It includes a locking structure that keeps the opening spring 4 in the compressed state after it is compressed in place.

[0019] The support base is a frame structure, and the support base also includes a support plate 8, a base plate 1, and a support column 2 connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com