Micro-cultivator

A micro tillage machine and frame technology, applied in the field of micro tillage machines, can solve the problems that the armrest frame cannot be rotated and adjusted, the micro tillage machine has a large dead angle of cultivation, and does not have a shock absorbing mechanism, so as to eliminate the difficulty of steering, eliminate the dead angle of cultivation, Rotate to adjust the effect conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

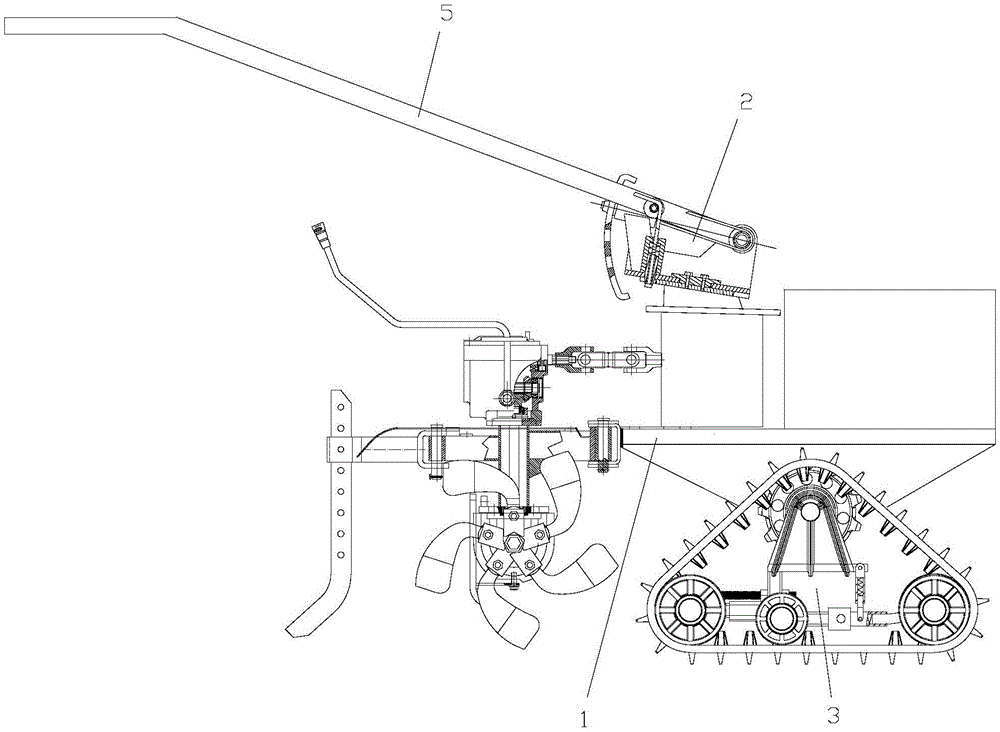

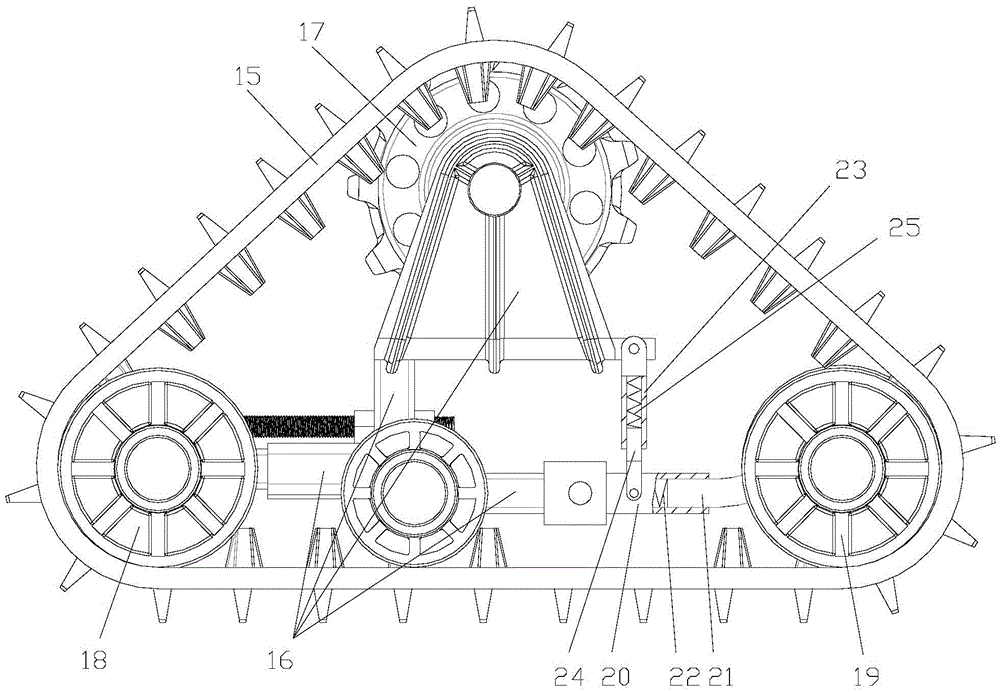

[0021] As shown in the figure, this embodiment includes a frame 1 on which a handrail frame device 2 and a crawler belt running mechanism 3 are arranged;

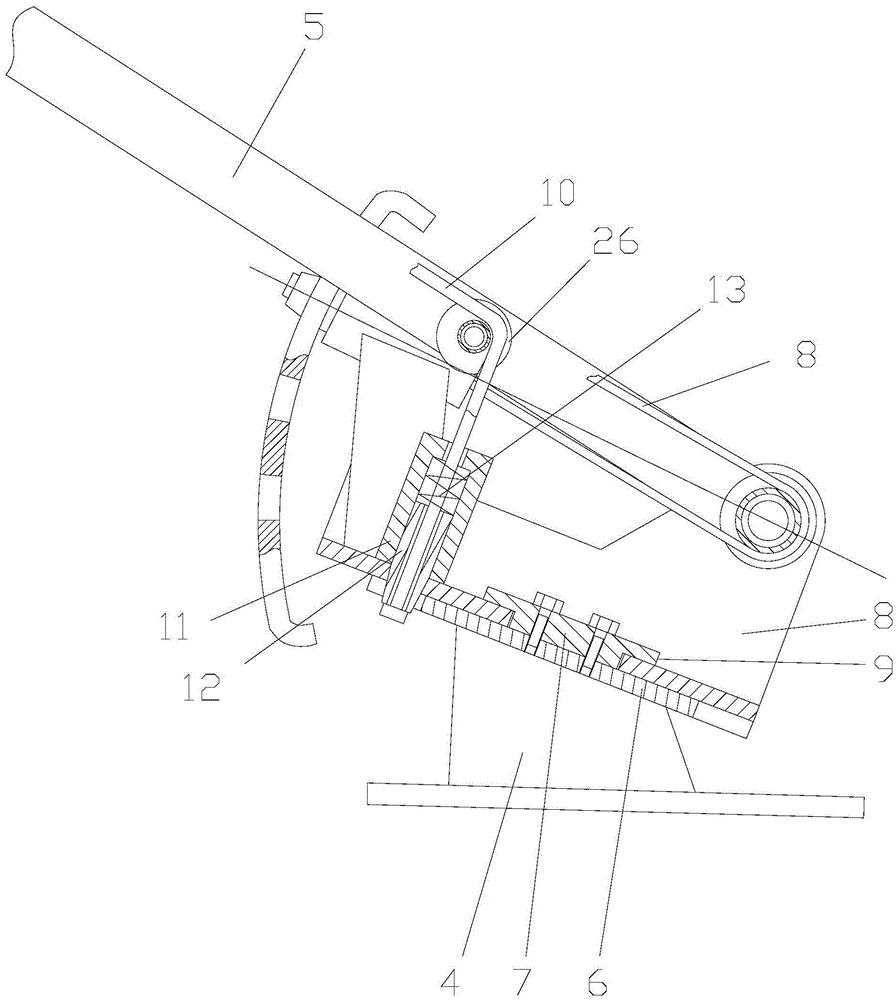

[0022] The armrest frame device includes a support 4 and an armrest frame 5, the support is fixedly connected with a rotating positioning disc 6, and the rotating positioning disc is fixedly connected with a positioning shaft 7 by screws, and the positioning shaft is covered with a rotating shaft 7 that is matched with its rotation. Seat 8, the upper end of the positioning shaft is also provided with an annular flange 9 to prevent the rotating seat from coming out in the axial direction;

[0023] The armrest frame device also includes a latch device and an adjustment cable 10, the latch device includes a latch sleeve 11 vertically fixedly connected to the swivel base, a latch 12 slidingly fitted with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com