Self-piercing adhesive riveting connection device and adhesive riveting method

A riveted connection and self-piercing technology, applied in furnaces, furnace types, heat treatment equipment, etc., can solve the problems of difficult deformation of ultra-high-strength steels, inability to form effective joints, etc., to increase the joint connection strength and reduce the thermal convection between plates. and heat radiation, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

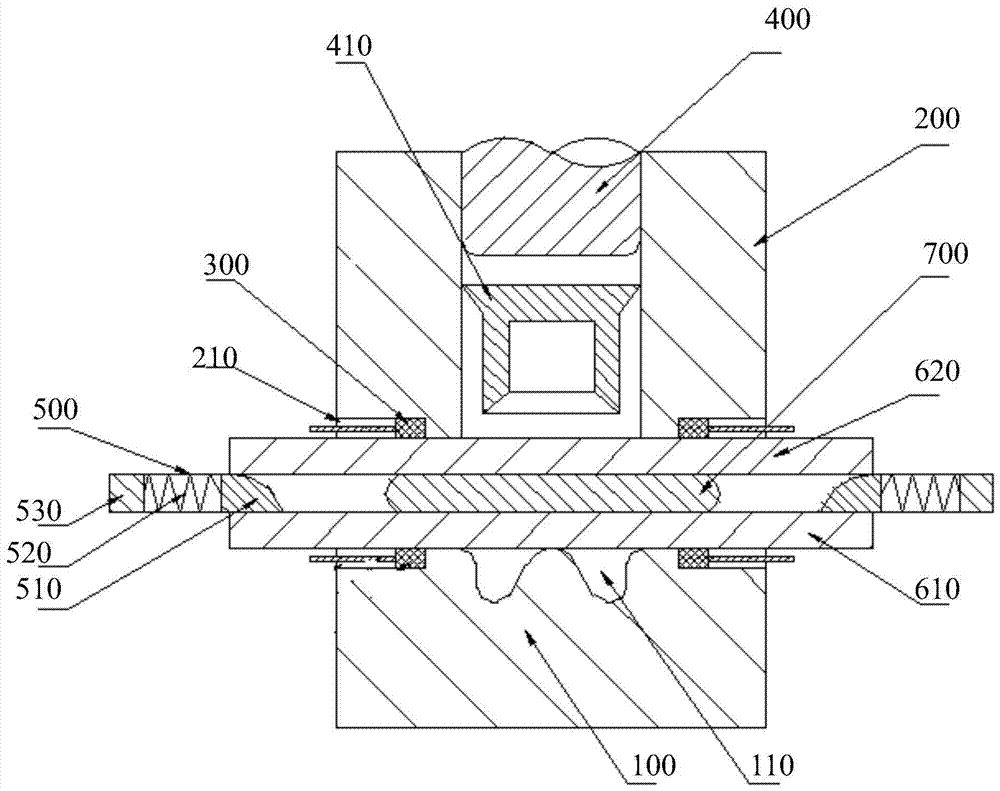

[0048] Such as figure 1 As shown, the self-piercing adhesive riveting connection device provided by the present invention includes: a composite die 100 , a composite blank holder 200 , a thermally conductive electrode 300 and a punch 400 .

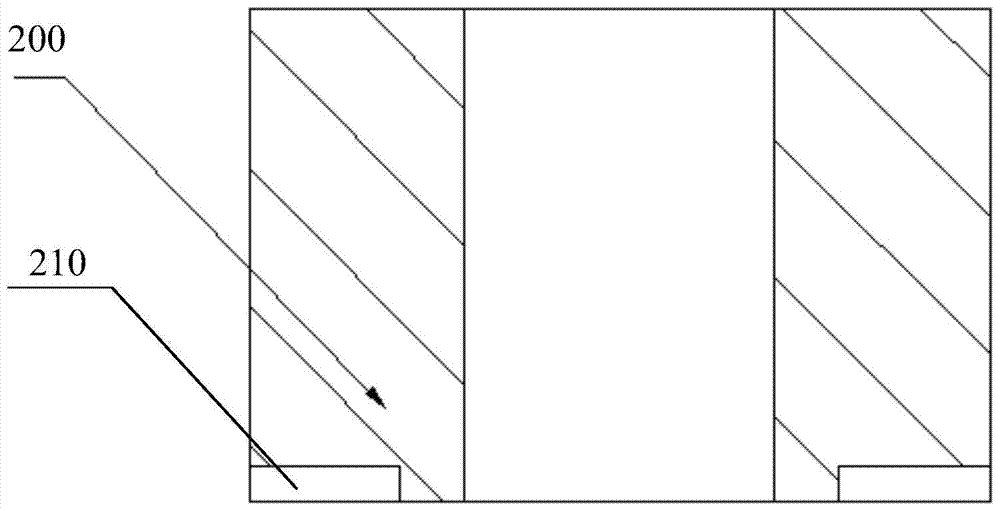

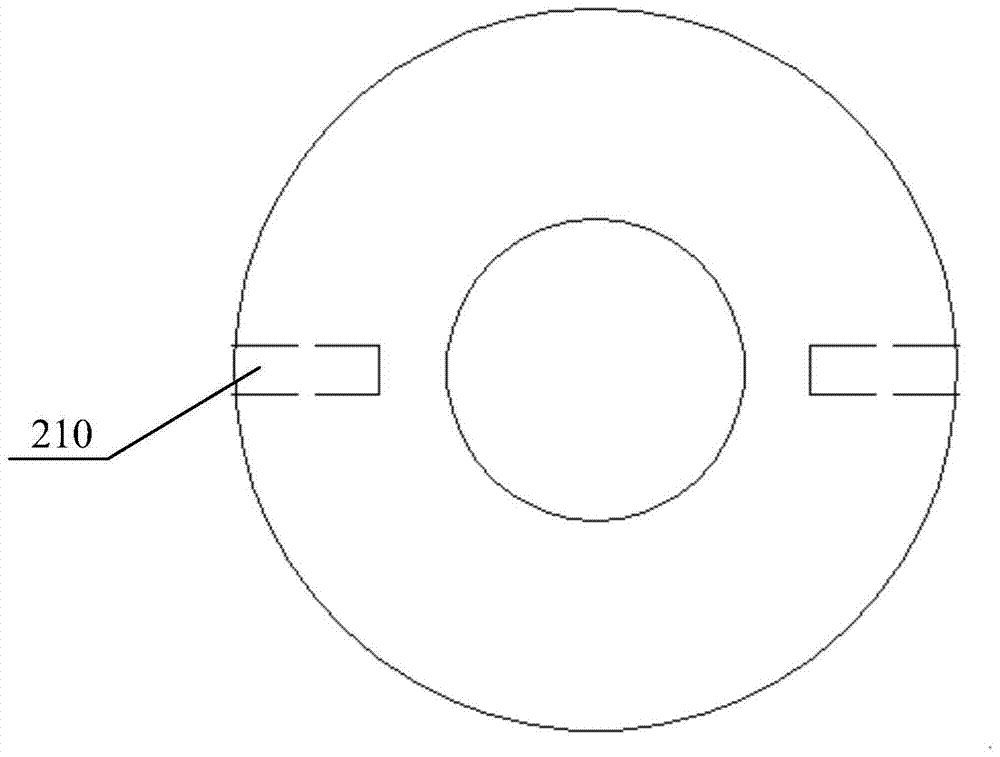

[0049] Such as Figure 2-3 As shown, the composite binder ring 200 is set opposite to the composite die 100, and the center of the composite binder ring 200 is provided with a through hole, and the bottom surface of the composite binder ring 200 is connected to the top surface of the composite die 100 in a contactable manner. On the bottom ring surface of the edge ring 200, a plurality of rectangular grooves 210 with the same structure are provided from the outside to the inside. The through hole at the center of the binder ring 200 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com