Self-punching riveting device of ultrahigh strength steel plate and aluminum alloy plate

A technology of aluminum alloy plate and self-piercing riveting, which is applied in metal processing equipment, forming tools, manufacturing tools, etc. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

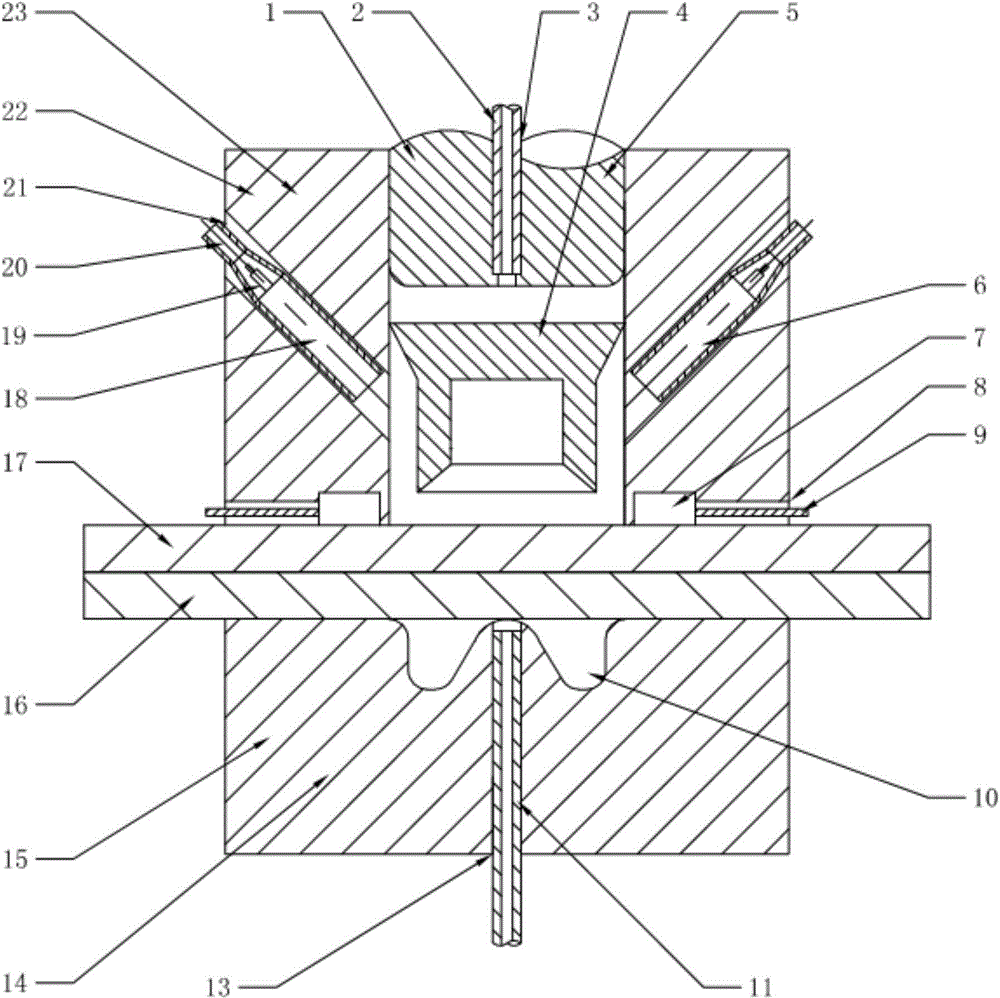

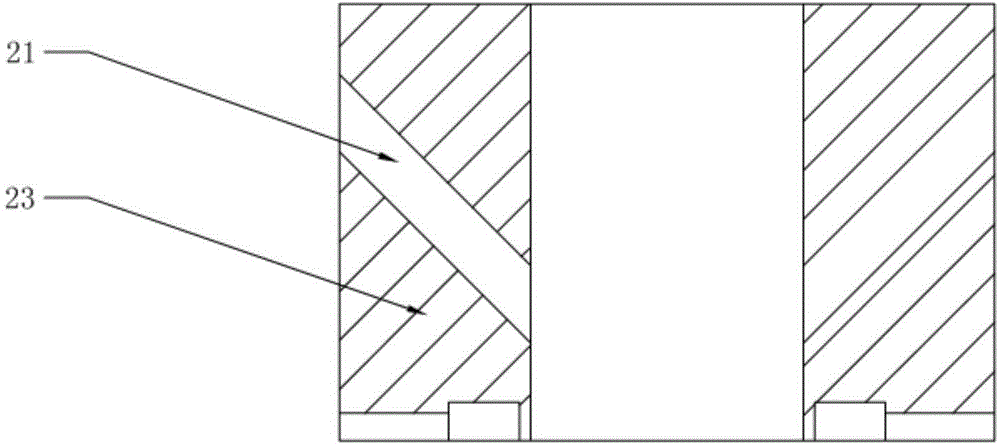

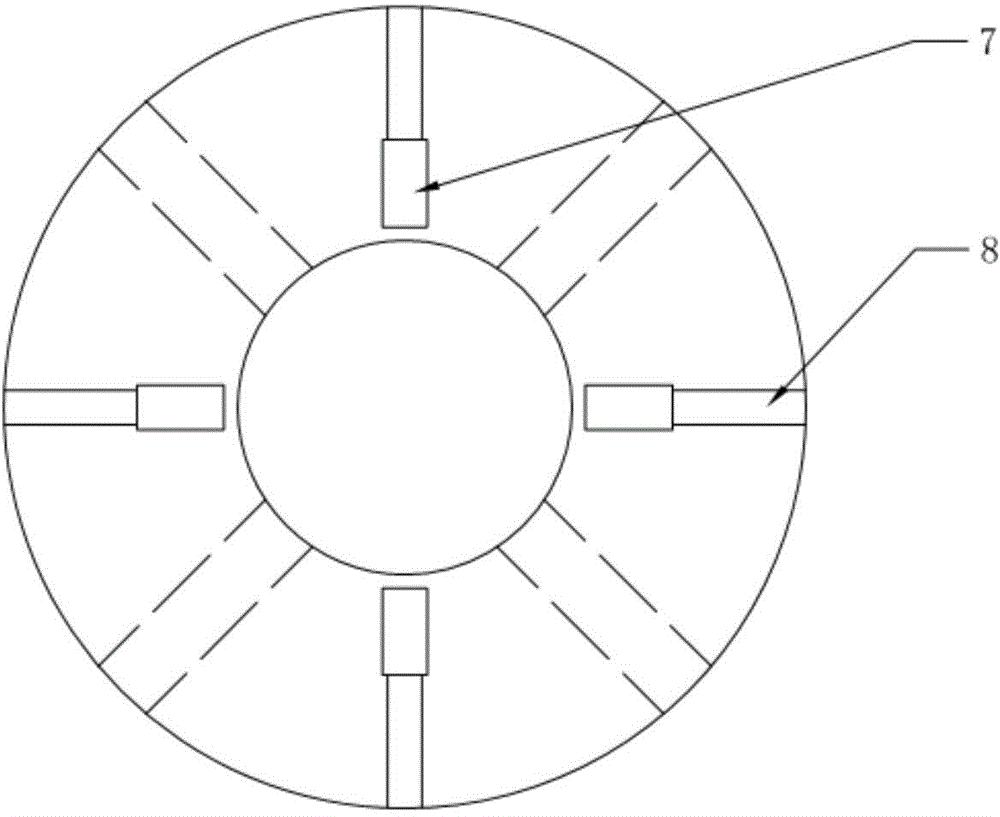

[0050] refer to figure 1 , The self-piercing riveting device of the ultra-high-strength steel plate and the aluminum alloy plate described in the present invention includes a composite punch 1 , a composite blank holder 22 , and a composite die 14 .

[0051] The composite blank holder 22 and the composite die 14 are stacked up and down, and the composite punch 1 is placed in the center hole of the composite blank holder 22 for sliding connection. The composite punch 1, the composite blank holder 22 and the composite die 14 The collinear axis of rotation is the coaxial arrangement.

[0052] refer to figure 1, the punch body 5 is a hollow cylindrical structure, the outer diameter of the punch body 5 is 5 mm, the fillet radius of the bottom edge of the punch body 5 is 0.5 mm, and the center of the punch body 5 is provided with a stepped hole in the axial direction, The upper section is the first hollow circular hole 3 with a diameter of 2mm, and the lower section has a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com