Continuous casting sheet billet cutting tracking method

A slab and continuous casting technology, applied in the field of continuous casting slab cutting and tracking, can solve the problems of human factors, low accuracy, and inability to accurately match the slab and the hot metal furnace number to which it belongs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

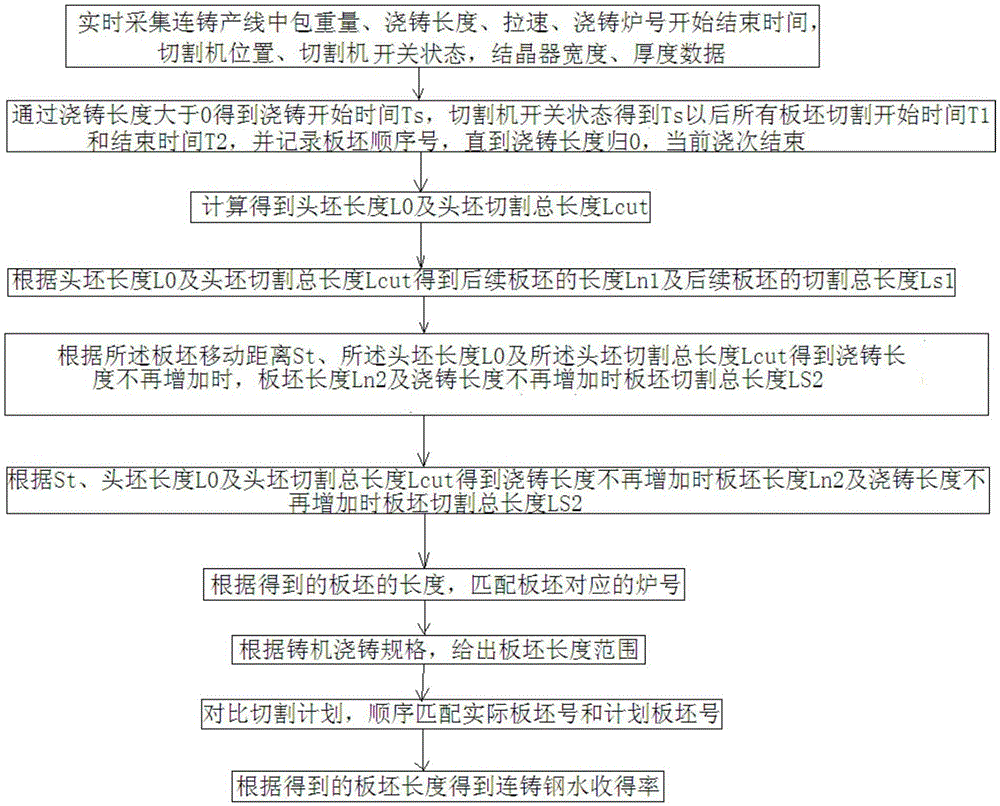

[0014] see figure 1 A continuous casting slab cutting tracking method provided in an embodiment of the present invention includes the following steps:

[0015] Step 1. Real-time collection of the weight of the continuous casting line, the casting length, the casting speed, the start and end time of the casting furnace number, the position of the cutting machine, the switch status of the cutting machine, and the width and thickness of the crystallizer.

[0016] Step 2: Obtain the casting start time Ts through the casting length greater than 0, get the start time T1 and end time T2 of all slab cutting after the cutting machine switch state after Ts, and record the sequence number of the slab until the casting length returns to 0, and the current casting time ends .

[0017] Step 3, calculate the length L of the head blank 0 And the total length of blank cutting L cut .

[0018] Step 4, according to the length L of the head blank 0 And the total cutting length L of the head ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap